Shaft rotation limiting mechanism, shaft system and three-position electric switch using the mechanism

A technology of shaft rotation and limit mechanism, applied in the direction of air switch parts, etc., can solve the problems of increasing the pressure of the transmission connection mechanism, no mechanical limit device, affecting the service life of the shaft system, etc., and achieves high locking accuracy and failure points. Less, accurate and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

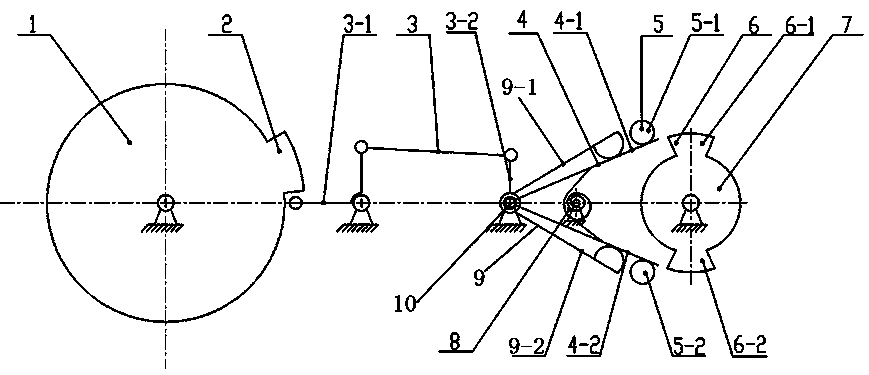

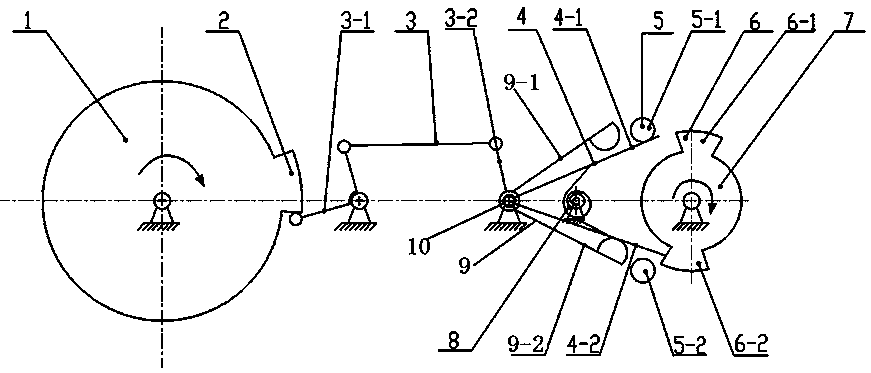

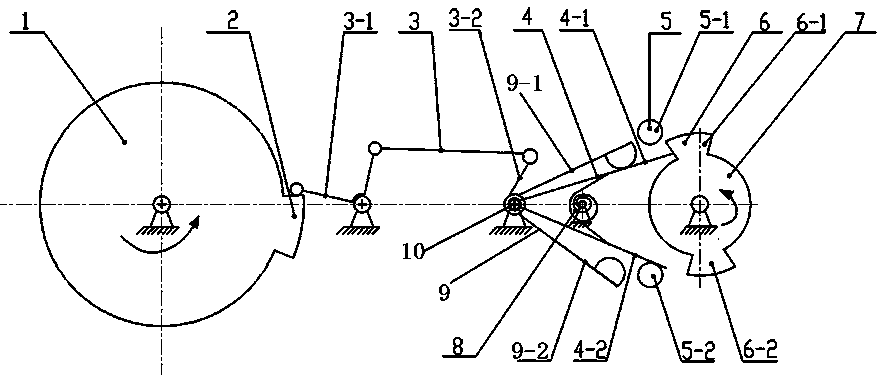

[0034] Such as Figure 1 to Figure 3 As shown, an embodiment of a shaft system using a shaft rotation limiting mechanism, the shaft system in this embodiment includes an input shaft 7 and an output shaft 1, and the input shaft 7 drives the output shaft 1 to rotate through a forward transmission mechanism, here The forward transmission mechanism is a commonly used transmission structure in the existing shaft system. The "forward" here refers to the transmission of the driving force from the input shaft 7 to the output shaft 1 in the transmission system.

[0035] The difference from the shaft system in the prior art is that in the shaft system provided in this embodiment, the output shaft 1 can limit the rotation of the input shaft 7 through the shaft rotation limiting mechanism of the reverse transmission. The rotation limiting mechanism includes a bracket, and the bracket is provided with a stop assembly 4, where the stop assembly 4 includes a clockwise stop bar 4-2 and an ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com