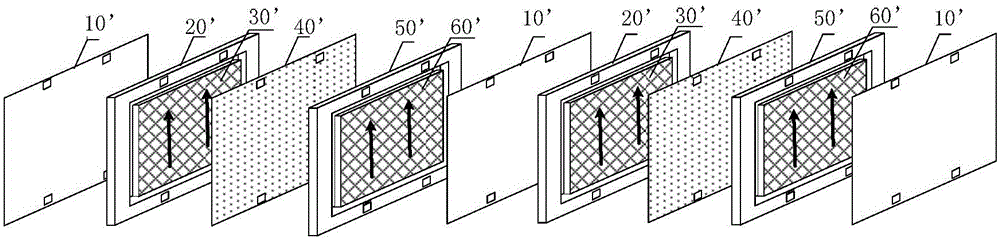

Electrode module for flow battery, preparation method of electrode module and battery stack containing electrode module

An electrode assembly and flow battery technology, applied in the field of battery stacks, can solve the problems of increased electrolyte flow resistance, increased system pump loss, reduced carbon felt porosity, etc., to improve energy efficiency, reduce contact resistance, Reduces the effect of sealing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

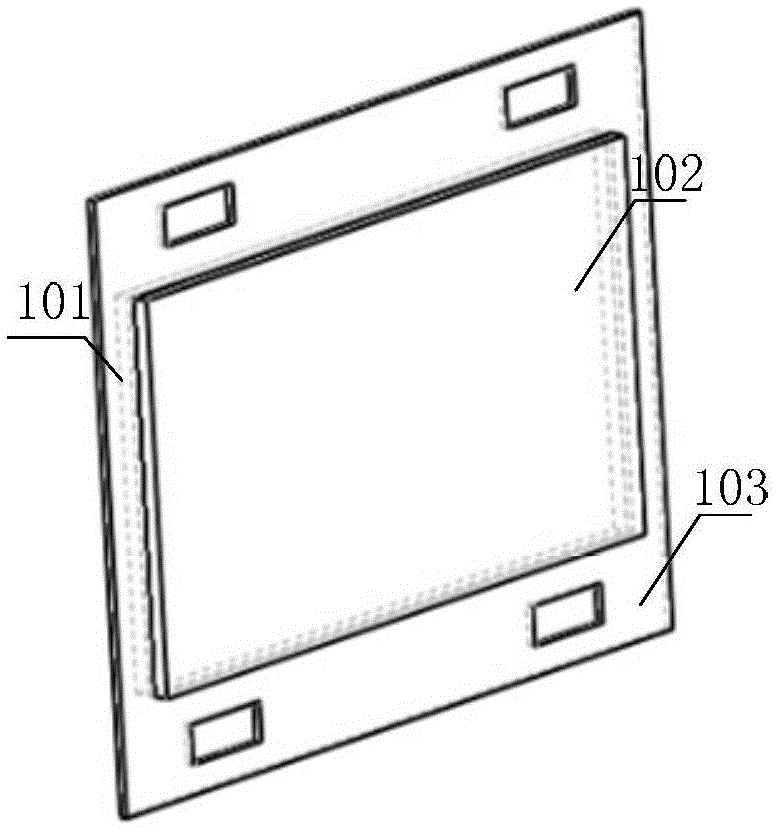

[0040]According to a typical embodiment of the present invention, the positive electrode porous electrode, the electrolyte separator and the negative electrode porous electrode are combined together by bonding, hot pressing or resin impregnation to form the first component, and the positive electrode flow frame is provided with a The first cavity of the positive electrode porous electrode, the second cavity for embedding the negative electrode porous electrode is arranged on the negative electrode flow frame, the positive electrode flow frame, the first part and the negative electrode flow frame are buckled together, the positive electrode flow frame and The negative flow frame is combined by bonding, hot pressing or laser welding. The combination of the positive porous electrode, the electrolyte separator and the negative porous electrode is just an example, and can also be combined in other ways in the art.

[0041] According to a typical embodiment of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com