Laminated articles having discontinuous bonded regions

A technology of bonding layer and bonding area, which is applied in the direction of layered products, textiles, papermaking, clothing, etc., can solve the problems of limitation of high tensile force, reduce stiffness, improve tensile performance, and improve spectrum reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

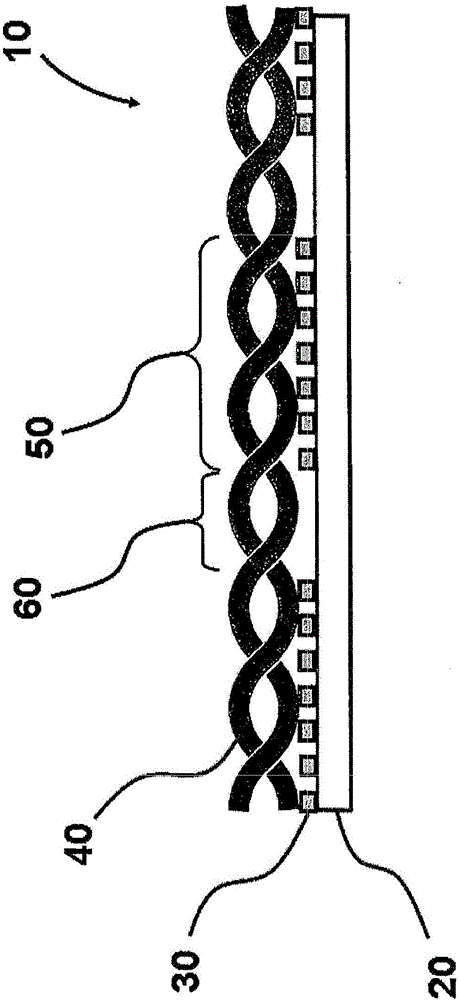

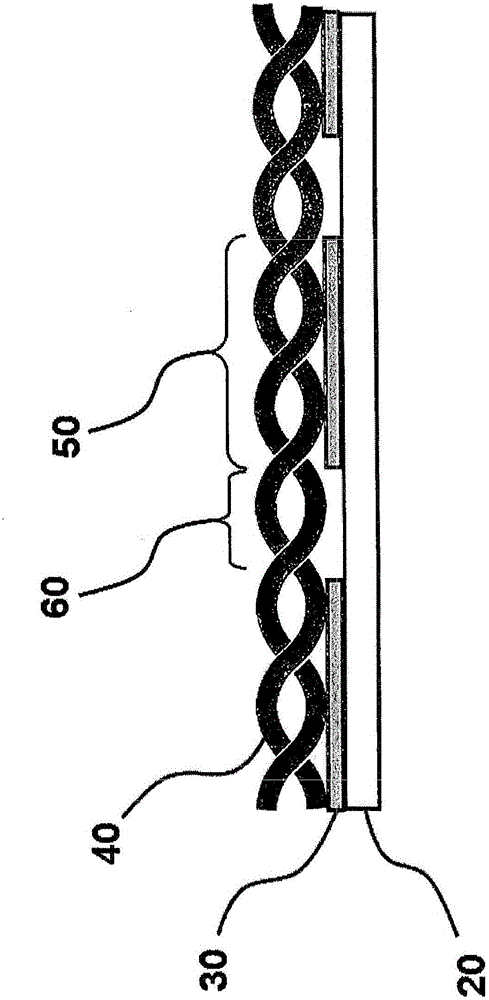

[0121] Get a section of 129g / m 2 Nylon / Stretch woven material (model GNS3, from Fumao Xingye Co., Ltd., Douliu City, Taiwan) and a length of ePTFE coated with polyurethane. The ePTFE has the following characteristics: the thickness is equal to 0.043 mm, the density is equal to 0.41 g / cubic centimeter, and the matrix tensile strength in the length direction is equal to 31×10 6 MPa, the tensile strength of the matrix in the width direction is equal to 93×10 6 MPa, bubble point is equal to 1.5×10 5 MPa. Polyurethane (PU) was applied by coating the ePTFE membrane and allowing it to at least partially penetrate the pores of the membrane and then allowed to cure.

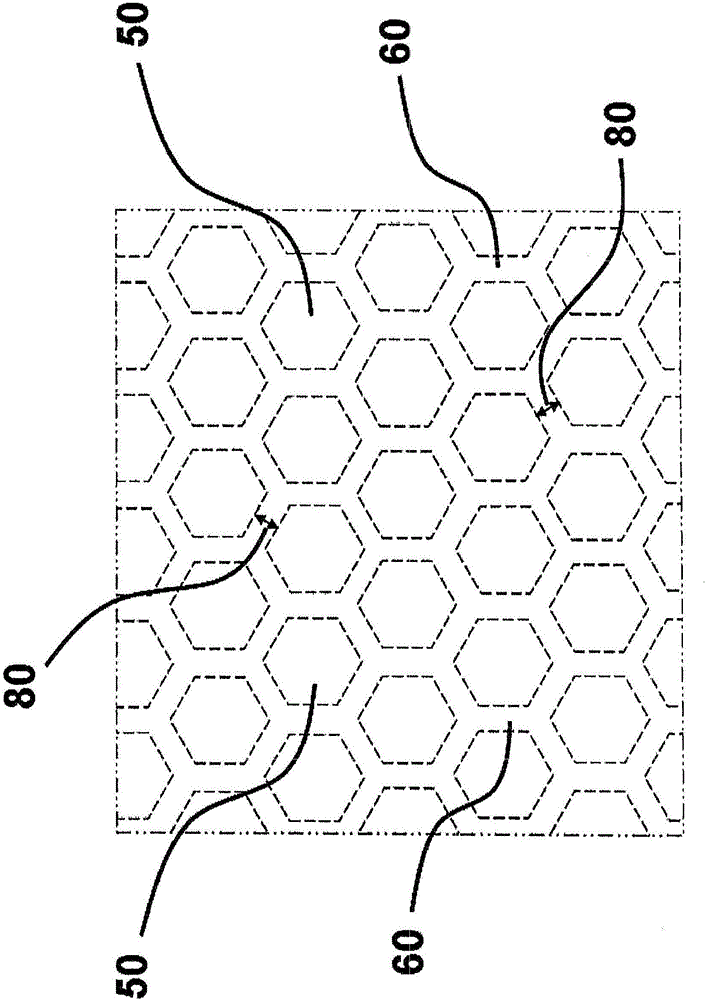

[0122] use Figure 12 The honeycomb (hexagonal) pattern shown was used to laser cut the release paper 215 . The hexagonal voids 220 were cut 10 mm wide and separated by release paper strips 230 4 mm wide. The release paper was positioned on the ePTFE side of the coated membrane, and the release paper and membrane...

Embodiment 2

[0127] Another laminate was formed as generally described in Example 1 with the following exceptions. The fabric is 93.2g / m 2 Nylon fabric (model 131913 from Milliken, Spartanburg, SC) with hexagonal voids in the release paper approximately 30 mm wide and separated by 6 mm wide release paper strips , the textile was not pre-stretched, additional adhesive dots were also applied to the coated side of the ePTFE, and a third textile layer—37.3 g / m 2 A polyester weave (model A1012 from GlenRaven, North Carolina) was added to the adhesive on the side opposite the nylon woven fabric.

[0128] The final laminate weighed 180g / m 2 . The water vapor transmission rate of this sample is 7,069g / m 2 / 24 hours. The sample is liquid impermeable but gas permeable. The thermal resistance per unit mass of the laminate is 0.024 (m 2 K / W) / (kg / m 2 ). The ratio of the thickness of the sample to the weight per unit area is 0.0021mm / (g / m 2 ). The flexural modulus in the bonding area was 11.3...

Embodiment 3

[0130] Obtain a section of 49.0g / m 2(Model 131907, Milliken & Company, Spartanburg, SC) and a length of ePTFE membrane. The ePTFE has the following characteristics: the thickness is equal to 0.126 mm, the density is equal to 0.402 g / cubic centimeter, and the matrix tensile strength in the length direction is equal to 28.5×10 6 MPa, the tensile strength of the matrix in the width direction is equal to 144.3×10 6 MPa, the bubble point is equal to 9.55×10 4 MPa. By using 12g / m 2 up to 15g / m 2 The ePTFE membrane was laminated to a 25.4 micron thick monomeric thermoplastic polyurethane film (part number PT1710S from Delphi Polyurethanes, South Deerfield, MA) with a continuous layer of air-permeable polyurethane adhesive applied at a coverage rate of Company (Deerfield Urethane)). The breathable polyurethane binder is a moisture cured polyether polyurethane binder as described in US Patent No. 4,532,316 to Robert Henn.

[0131] The patterned rubber roller is composed of a plu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com