Grooved roller type separating and broken seedling removing mechanism of potato tubers

A technology of potatoes and grooved rollers, which is applied in the direction of topping machines, digging harvesters, harvesters, etc., can solve problems such as troublesome operations, complex structures, and unsatisfactory separation effects, and achieve increased frictional pulling force and improved The effect of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

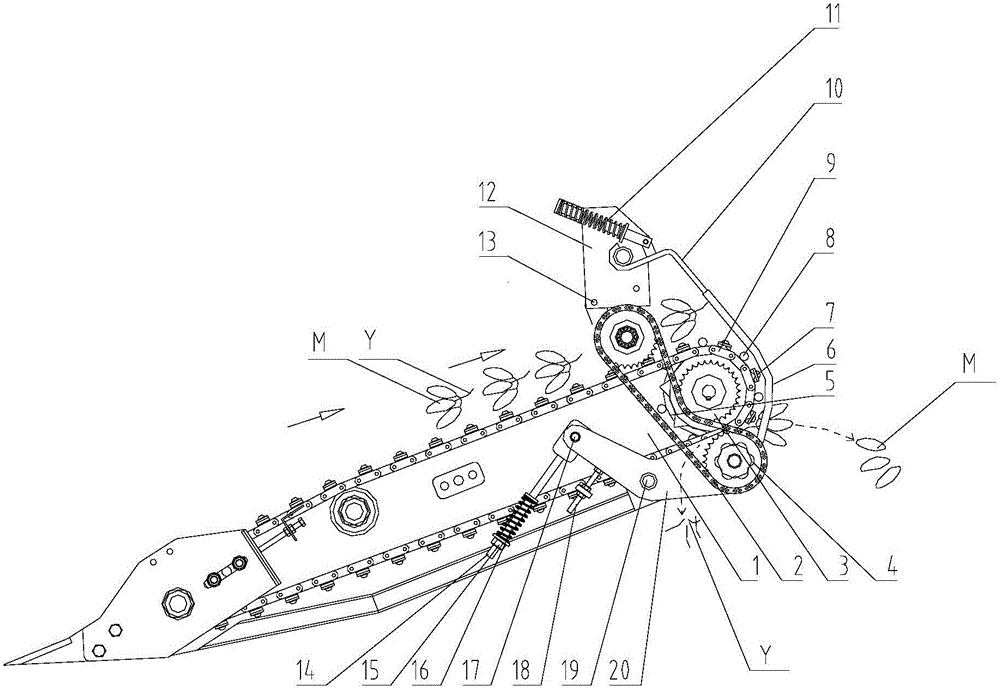

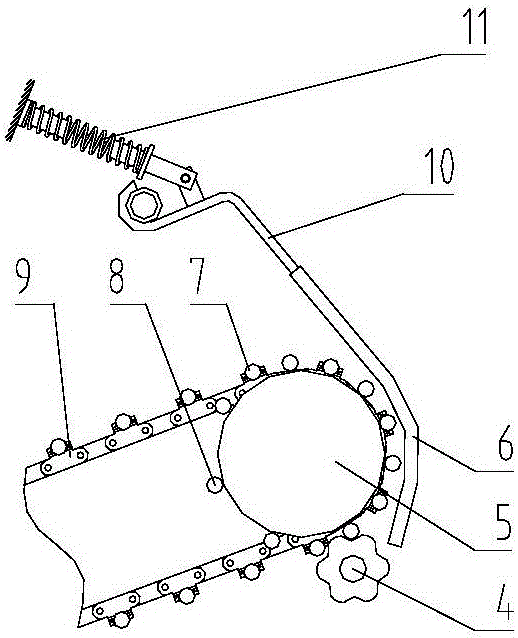

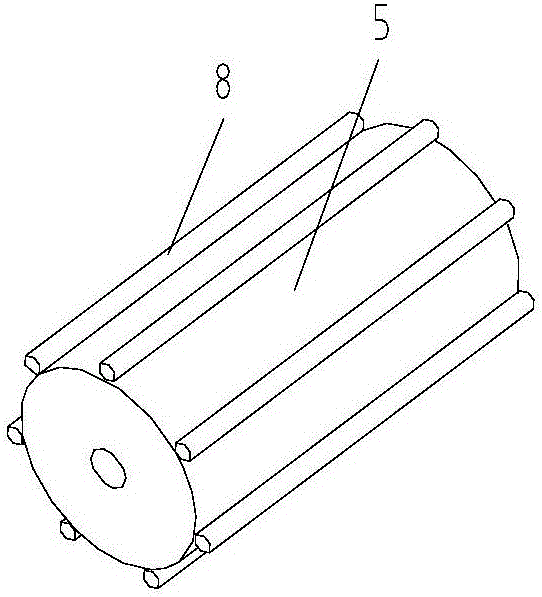

[0020] The grooved roller type potato tuber separation and residual seedling removal mechanism of the present embodiment is as follows: figure 1 and figure 2 As shown, the conveying rod lifting chain 9 is surrounded on the excavating conveying device 1 at the front end of the potato combine harvester, and the high end of the conveying rod lifting chain 9 is equipped with a rod pressing roller 5 driven by a power device. Bar top pressure roller 5 such as image 3 As shown, when the outer circumference is uniformly distributed, it is positioned at the pressing roller bars 8 between the interval distribution lifting chain bars.

[0021] The top of the bar pressing roller 5 is equipped with an elastic bar mechanism 12 mainly composed of an elastic curved bar 10 and an elastic bar compression spring 11. The upper end of the elastic curved bar 10 is hinged on the frame, and the lower end Extending from the elastic bar mechanism, it is an arc section matching the outer circle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com