Self-propelled fallen jujube sweeping and picking machine

A pick-up and self-propelled technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as difficulty in harvesting jujubes on the ground, affecting the economic benefits of jujubes, and being unsuitable for harvesting jujubes, achieving compact structure and external dimensions. Small, good ground profiling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

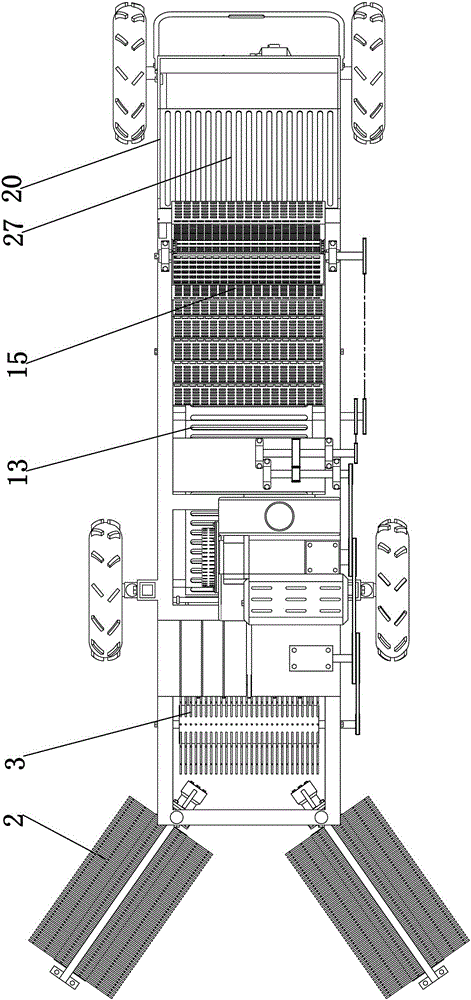

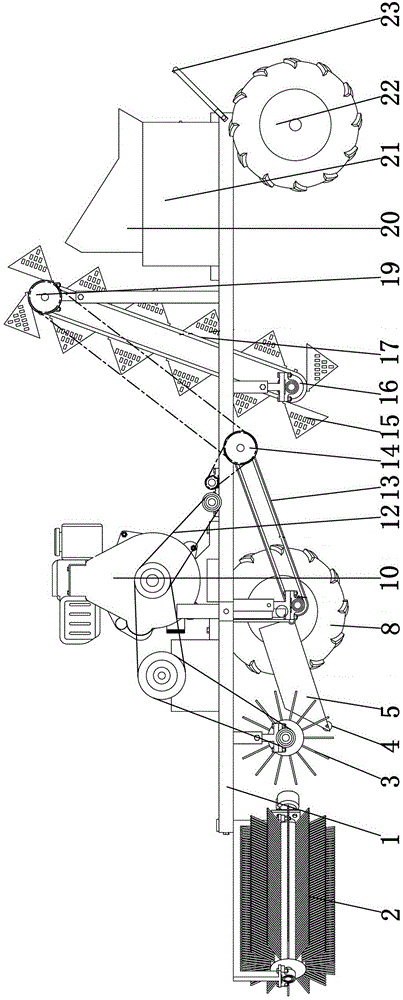

[0009] A self-propelled landing red date cleaning and picking machine, such as figure 1 , figure 2 Shown, comprise the frame 1 that front road wheel 8 and rear road wheel 22 are housed, frame 1 rear end is provided with handrail 23. Two horizontally arranged collection roller brushes 2 are installed under the front end of the frame 1, and the two roller brushes 2 are arranged in a V shape. A sweeping roller 3 is horizontally arranged under the frame at the back of the roller brush 2, and a jujube shovel 5 is hinged on the lower frame of the sweeping roller 3 rear, and a profiling wheel 4 is arranged under the bottom surface of the front end of the jujube shovel 5 to adapt to the unevenness of the ground . Jujube shovel 5 front ends stretch to under cleaning roller 3 roller brushes. Jujube shovel 5 rear end frame is inclined to be equipped with an impurity removal conveyer belt 13 by pulley 9,14, and the lifting belt 17 of inclined arrangement is equipped with in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com