Hemerocallis citrina processing method

A processing method, the technology of day lily, is applied in the direction of preserving fruits/vegetables through dehydration, which can solve the problems of lower quality and effective nutrients, lack of availability of day lily, and large output, so as to prevent mold and deterioration and improve production efficiency , reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

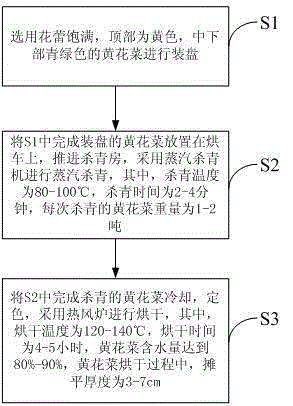

[0027] A kind of day lily processing method, comprises the following steps:

[0028] S1: Packing: select the day lily with full flower buds, yellow top, and turquoise middle and lower part;

[0029] S2: Finishing: Place the daylilies that have been plated in S1 on a drying car, push them into the finishing room, and use a steam curing machine for steam finishing. The temperature for finishing is 90°C, and the time for finishing is 3 minutes. Vegetables weigh 1.5 tons;

[0030] S3: Drying: Cool the day lily that has been completed in S2, fix the color, and dry it with a hot air stove. The drying temperature is 130°C, and the drying time is 4.5 hours. The water content of the day lily reaches 85%. During the drying process of vegetables, the flattened thickness is 5cm.

Embodiment 2

[0032] A kind of day lily processing method, comprises the following steps:

[0033] S1: Packing: select the day lily with full flower buds, yellow top, and turquoise middle and lower part;

[0034] S2: Finishing: Place the daylilies that have been plated in S1 on a drying car, push them into the finishing room, and use a steam cleaning machine for steam finishing. The temperature for finishing is 100°C, and the time for finishing is 2 minutes. Vegetables weigh 2 tons;

[0035] S3: Drying: Cool the day lily that has been completed in S2, fix the color, and dry it with a hot air stove. The drying temperature is 120°C, and the drying time is 5 hours. The water content of the day lily reaches 80%. During the drying process of vegetables, the flattened thickness is 7cm.

Embodiment 3

[0037] A kind of day lily processing method, comprises the following steps:

[0038] S1: Packing: select the day lily with full flower buds, yellow top, and turquoise middle and lower part;

[0039] S2: Finishing: Place the daylilies that have been plated in S1 on a drying car, push them into the finishing room, and use a steam cleaning machine for steam cleaning. The temperature for finishing is 95°C, and the time for finishing is 2.5 minutes. Vegetables weigh 1.7 tons;

[0040] S3: Drying: Cool the day lily that has been completed in S2, fix the color, and dry it with a hot air stove. The drying temperature is 125°C, and the drying time is 4.8 hours. The water content of the day lily reaches 82%. During the drying process of vegetables, the flattened thickness is 6cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com