Coarse crushing and sorting process

A coarse-grain and sorting technology, applied in grain processing and other directions, can solve the problems of small screening processing capacity, large screen wear and high wear, and achieve the effect of avoiding equipment wear, high power consumption, and high equipment failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

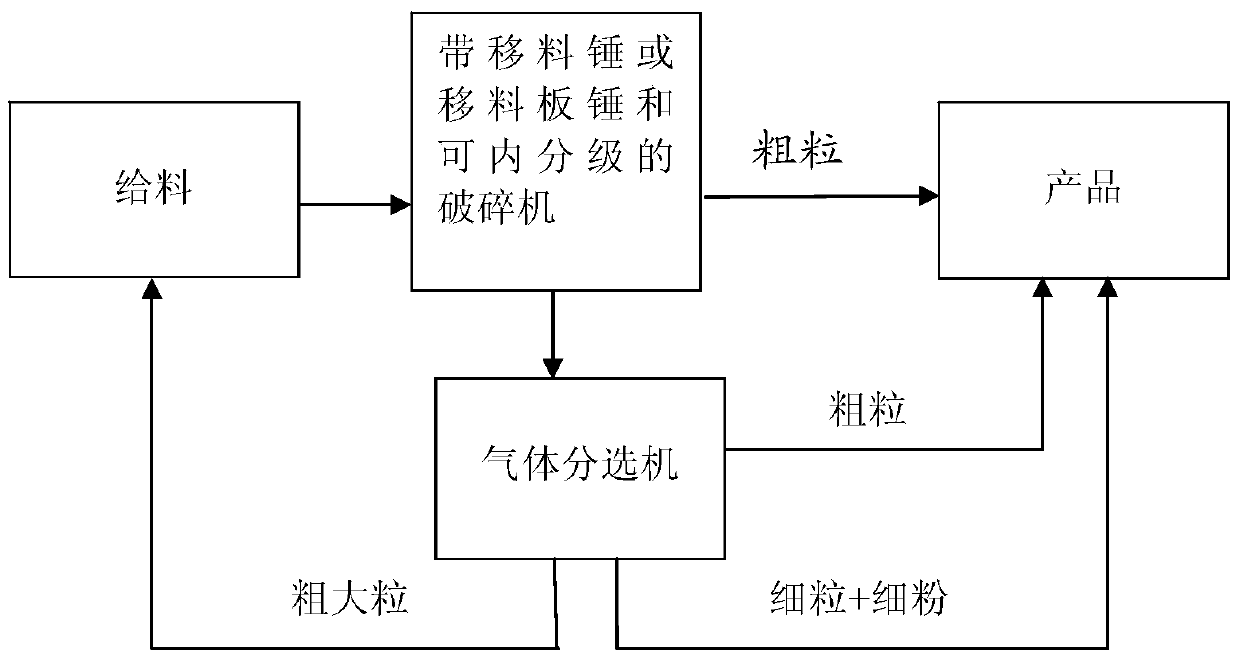

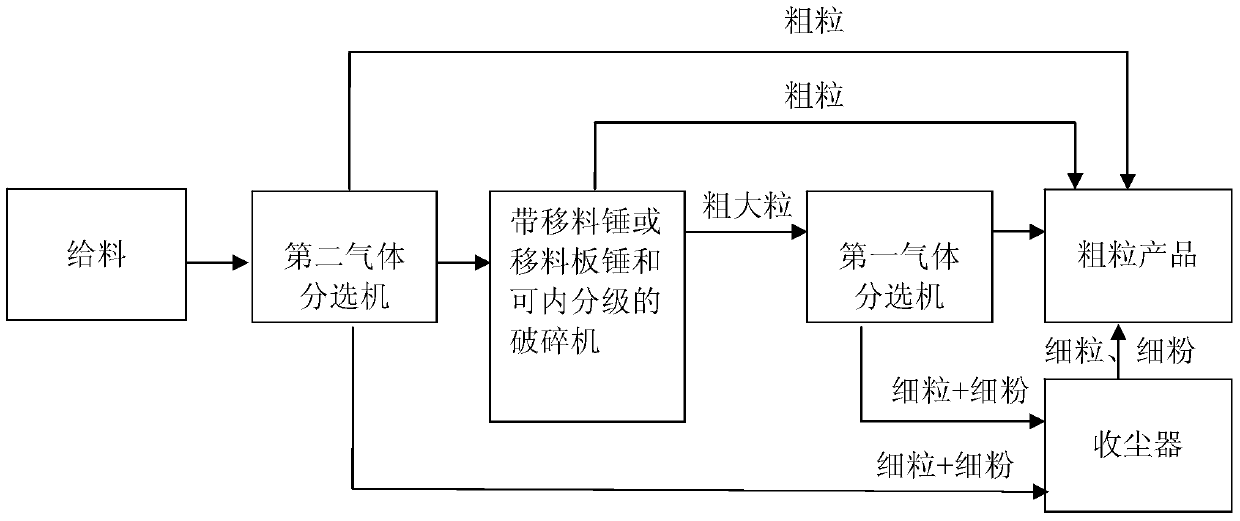

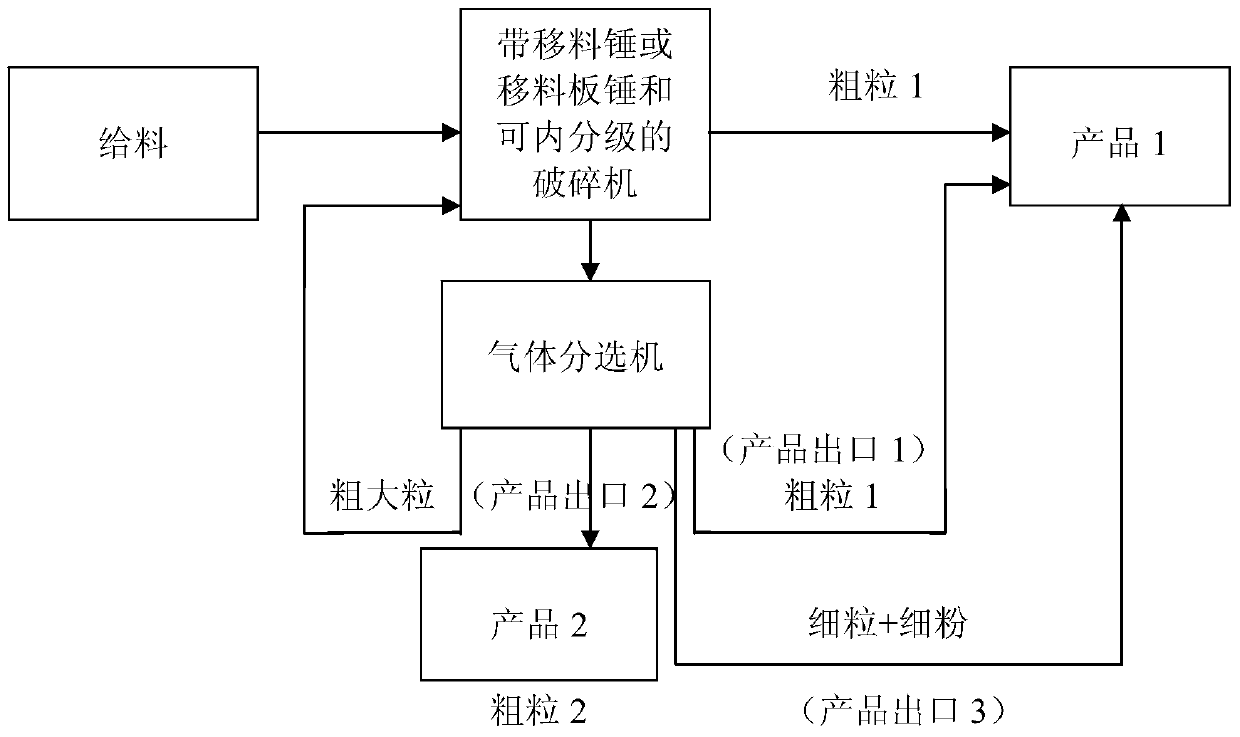

[0028] This specific embodiment provides a coarse grain crushing and sorting process. The process adopts a gas sorter capable of coarse grain sorting and an internal The graded crusher, for coarse crushing and sorting, can effectively improve production efficiency, and has a large output, low energy consumption, and relatively low wear on equipment.

[0029] The invention provides a coarse crushing and sorting process, comprising the steps of:

[0030] S01, the material is crushed while being conveyed on the sieve plate in the crusher with a shifting hammer or a shifting blow bar and a grading machine, that is, the screen, and the material screened from the screen is crushed by a shifting hammer or a shifting blow bar. And the first outlet of the crusher that can be internally classified is discharged and collected as coarse-grained products, and the materials that have not been sieved from the screen are conveyed along the screen to the crusher with moving hammer or moving ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com