Adjusting method of slab caster roll gap under unsteady state pouring condition

A technology of slab continuous casting machine and adjustment method, which is applied in the field of continuous casting production technology, can solve problems such as cracks in the middle of the slab, stagnation of the slab, and increased resistance to casting slab, so as to avoid excessive strain of the slab, reduce degradation or Waste, the effect of avoiding sudden changes in the roll gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

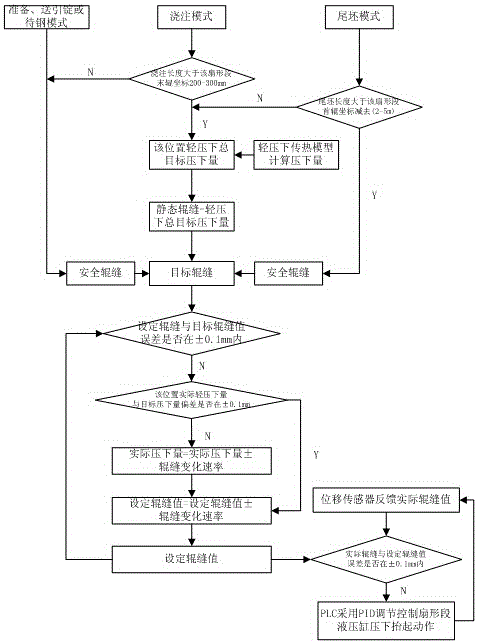

[0022] The present invention is a method for adjusting the roll gap of a slab continuous casting machine under unsteady pouring conditions, comprising the following steps:

[0023] (1) At least 2 incremental encoders are installed on different segment drive motors, which are used to calculate the length of the billet during the pouring stage and the length of the tail billet during the stage of drawing the tail billet;

[0024] (2) Set the safety roll gap as the thickness of the upper mouth of the crystallizer;

[0025] (3) Set the static roll gap as the free shrinkage roll gap value when dynamic light reduction is not used;

[0026] (4) Set the roll gap change rate to 0.02mm / s-0.04mm / s;

[0027] (5) In the mode of pouring preparation, dummy bar delivery, and pouring stop, set the target roll gap value as the safe roll gap value in step (2);

[0028] (6) In the pouring stage, the length of the billet is calculated by one of the encoders installed on the drive motor of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com