Twisting and measuring machine for main cone nut of drive axle assembly

A technology of drive axle assembly and main cone nut, which is applied in the direction of measuring torque/torsional force, metal processing, metal processing equipment, etc. during tightening, which can solve problems such as inaccurate measurement results, reduce costs, reduce intermediate links, and improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

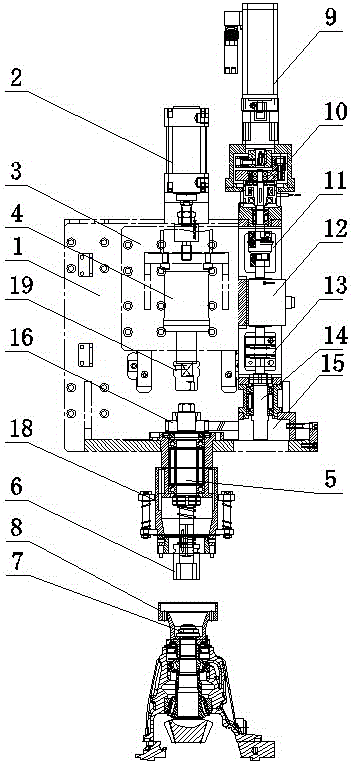

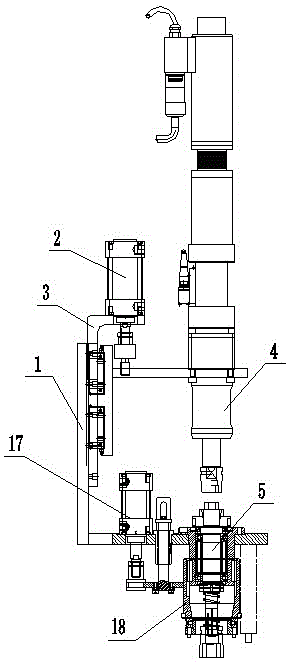

[0013] See figure 1 , the main cone nut tightening machine for the drive axle assembly, including the main cone nut tightening mechanism, the turning moment measuring mechanism and the anti-rotation mechanism; the main cone nut tightening mechanism includes a sliding table drive cylinder 2 connected sequentially from top to bottom, sliding connection Install the slide table 3, the tightening shaft 4 and the common shaft 5 on the positioning plate 1, the bottom end of the tightening shaft 4 is provided with a tightening shaft connecting sleeve 19, and the tightening shaft connecting sleeve 19 is set on the top of the common shaft 5, and the common shaft 5 The bottom is provided with a tightening measurement 6, and the tightening measurement 6 is set on the main cone nut 7; the rotary torque measurement mechanism includes a servo motor 9, a clutch 10, an upper coupling 11, a torque sensor 12, and a lower coupling sequentially connected from top to bottom Device 13 and drive bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com