Large-size radial ultrasonic auxiliary end face grinding abrasive disk

An ultrasonic-assisted, end-face grinding technology, used in grinding/polishing equipment, machine tools suitable for grinding workpiece planes, grinders, etc., can solve problems such as difficulty in realizing large-size grinding discs or ultrasonic vibration of workpieces, and achieve improved rigidity. , The effect of reducing transmission and improving radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

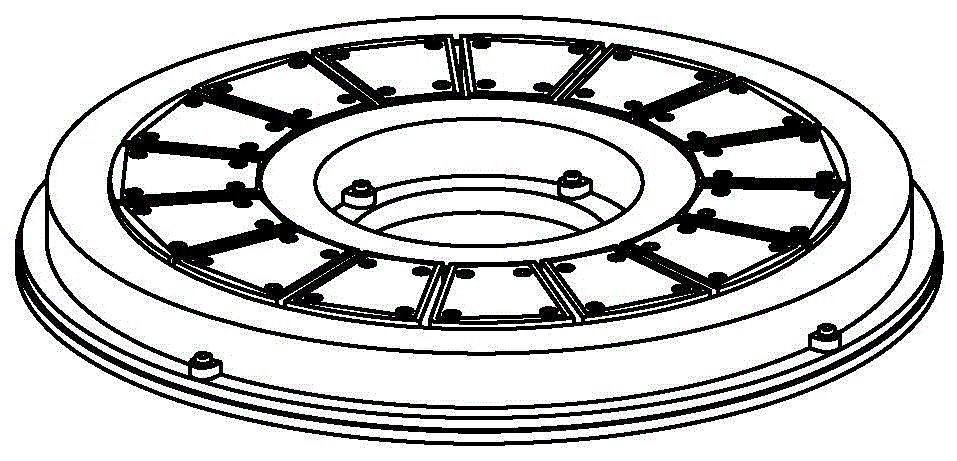

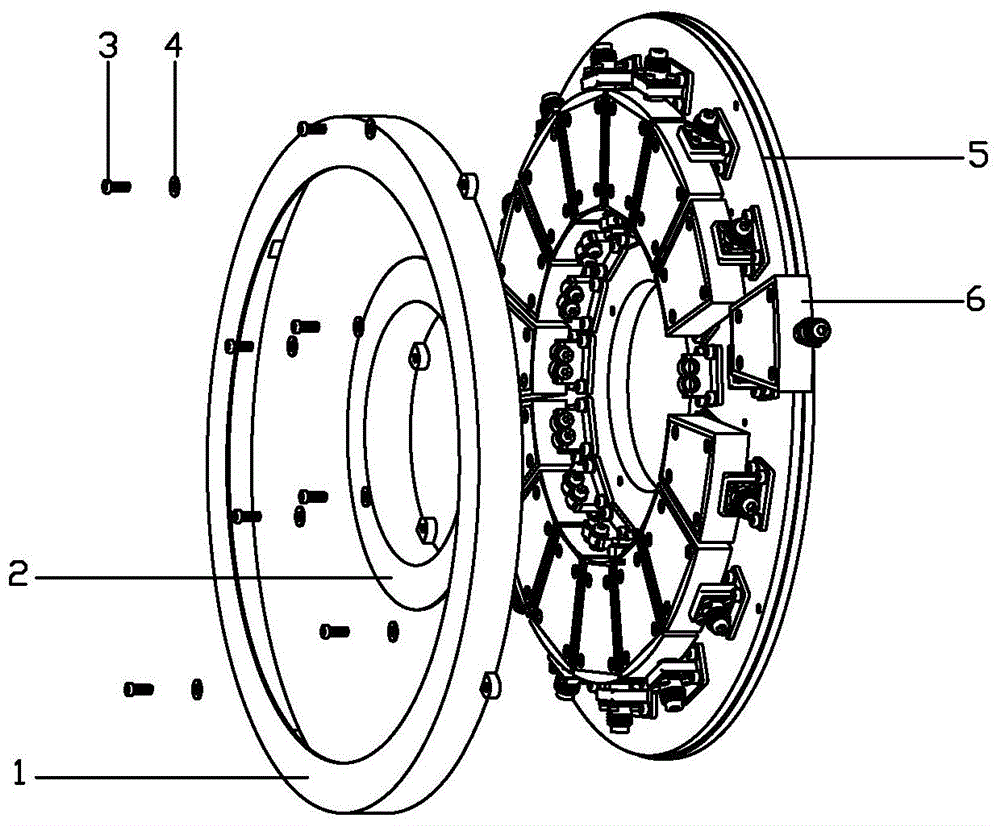

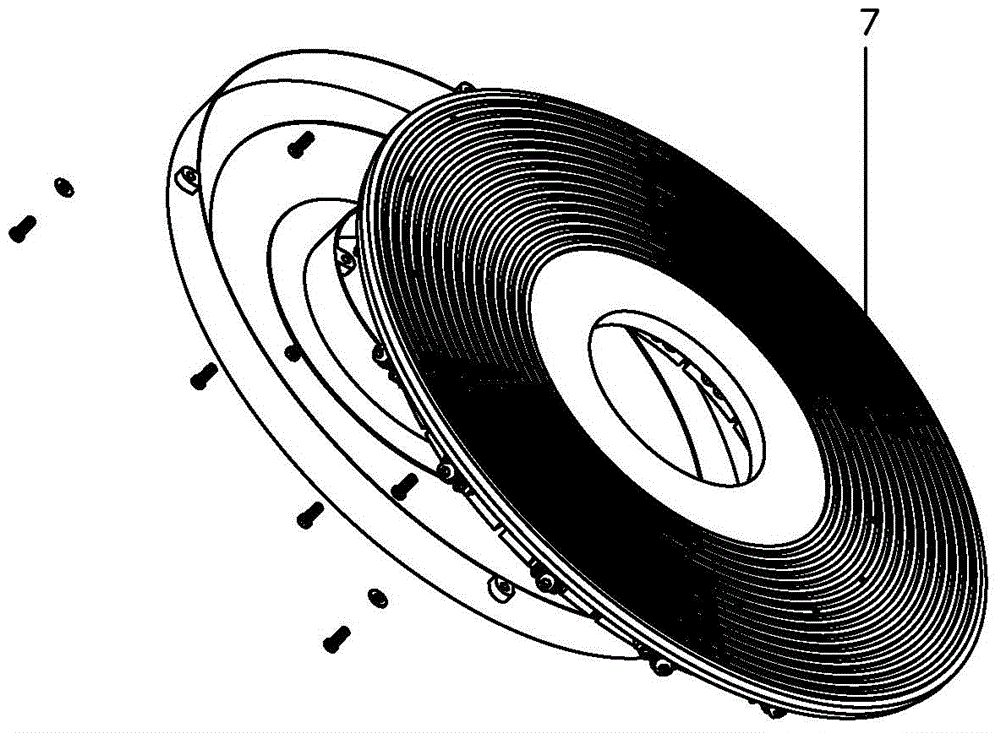

[0036] see figure 1 with figure 2 As shown, a large-size radial ultrasonic-assisted end face grinding grinding disc of the present invention includes: an outer cover 1, an inner cover 2, a base plate 5, a number of magnetic support seats 33, a horn support seat 34 and an ultrasonic vibrating block 6 ;

[0037] The plurality of ultrasonic vibrating blocks 6 are evenly distributed along the circumferential direction of the base plate 5, and assembled into a large-sized annular grinding disc to realize radial ultrasonic vibration of the grinding disc; the ultrasonic vibrating mass 6 is composed of ultrasonic transducers 13, The horn 12, the magnetic rod 8 and the grinding block 9 are composed; one end of each ultrasonic vibration block 6 is fixed on the base plate 5 through the zero amplitude of the horn 12, and the other end is supported by a magnetic force installed on the base plate 5. The seat 33 supports the magnetic rod 8 at the end of the ultrasonic vibration block 6 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com