Elevating type pipeline protective layer synchronous molding device

A technology of shaping device and protective layer, which is applied in the field of synchronous shaping device for liftable pipeline protective layer, can solve the problems of large manpower and material resources, large space, large volume, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

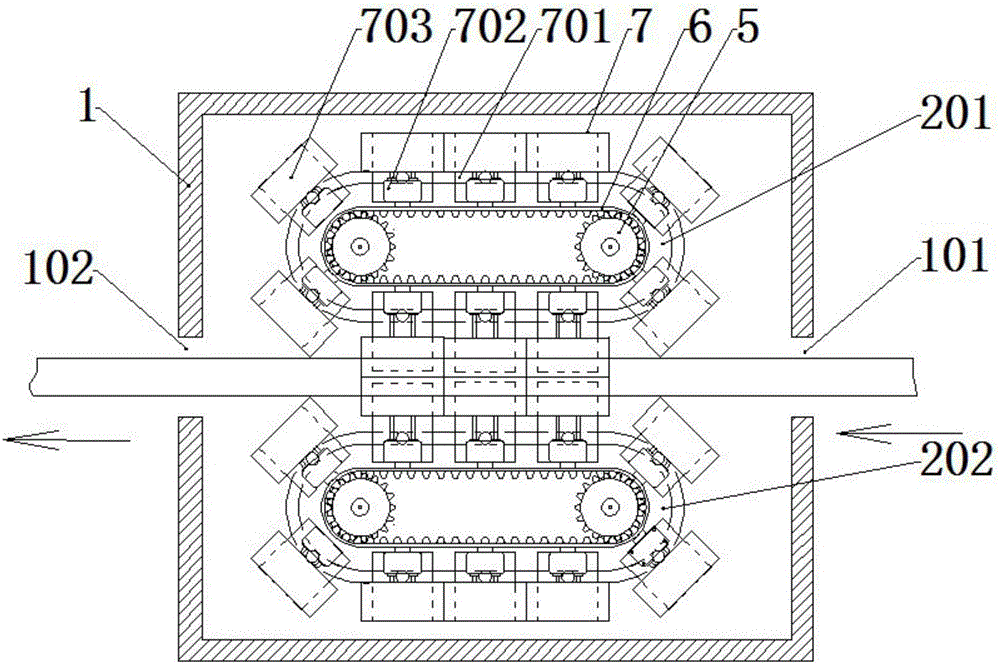

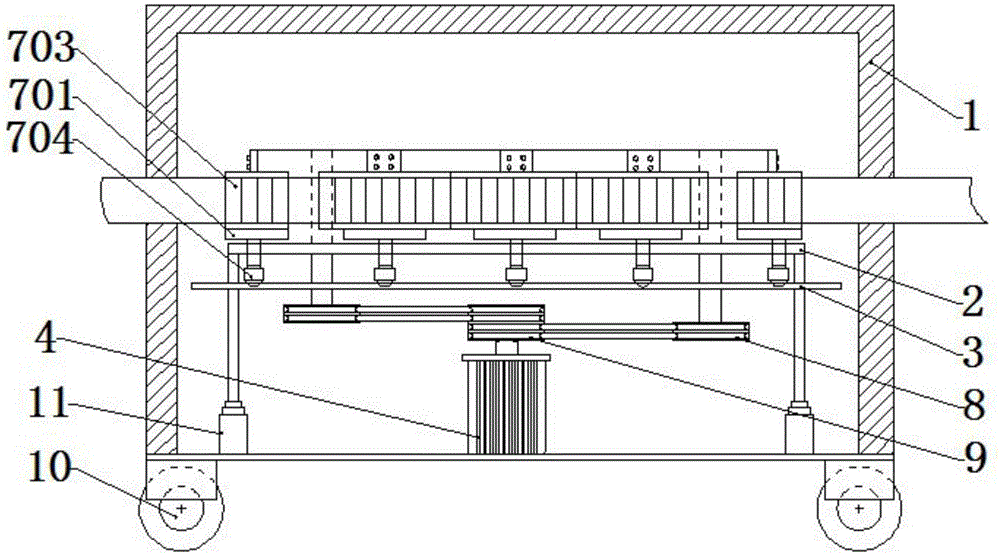

[0025] A liftable pipeline protective layer synchronous shaping device, comprising: a box body (1), a workbench (2), a guide rail (3), a motor (4), a sprocket (5), a timing belt (6), Sizing device (7), small pulley (8), large pulley (9), roller (10), oil cylinder (11); said box body (1) is provided with pipeline inlet (101) and pipeline outlet (102); Described workbench (2) comprises No. I workbench (201) and No. II workbench (202), and described No. I workbench (201) and described No. II workbench (202) are respectively fixed on On both sides of the inside of the box (1), the guide rails (3) are installed below the workbench (2); the motor (4) is fixed on the bottom plate of the box (1), and the The main shaft of the motor (4) is connected with the large pulley (9), and the large pulley (9) is connected with the small pulley (8) through a V-shaped belt; The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com