Making device and method for soft glass optical fiber preform

A technology for optical fiber preforms and manufacturing devices, which is applied in glass manufacturing equipment, manufacturing tools, etc. It can solve the problems of difficult to obtain core layer preforms, difficult timing and lifting height, and difficult to produce glass rods with excellent optical uniformity. and other problems, to avoid surface devitrification effect, ensure optical uniformity, and achieve the effect of excellent optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

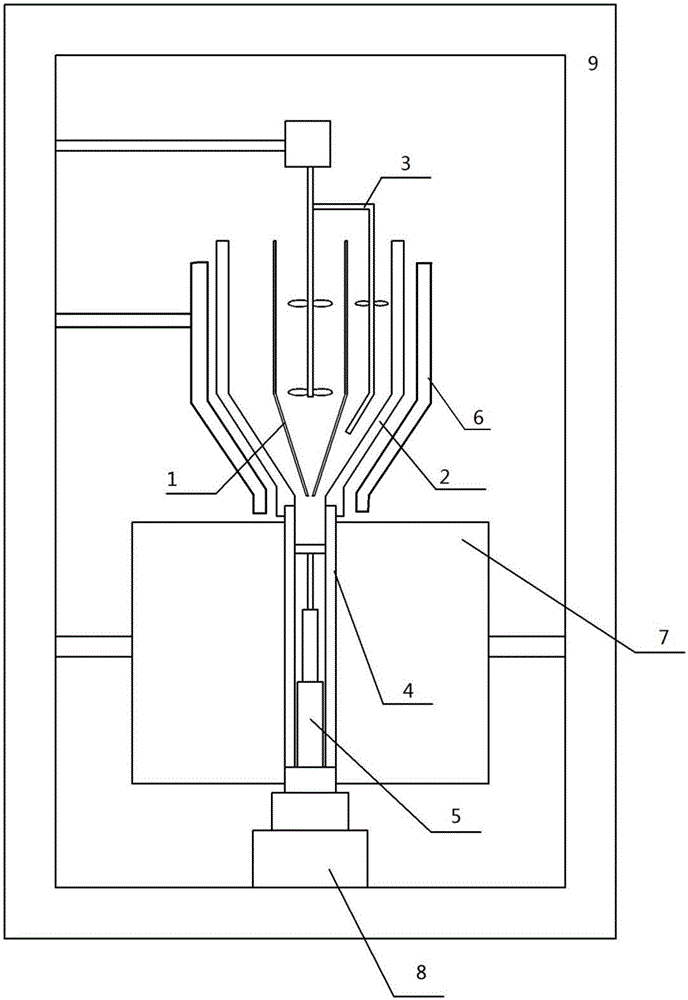

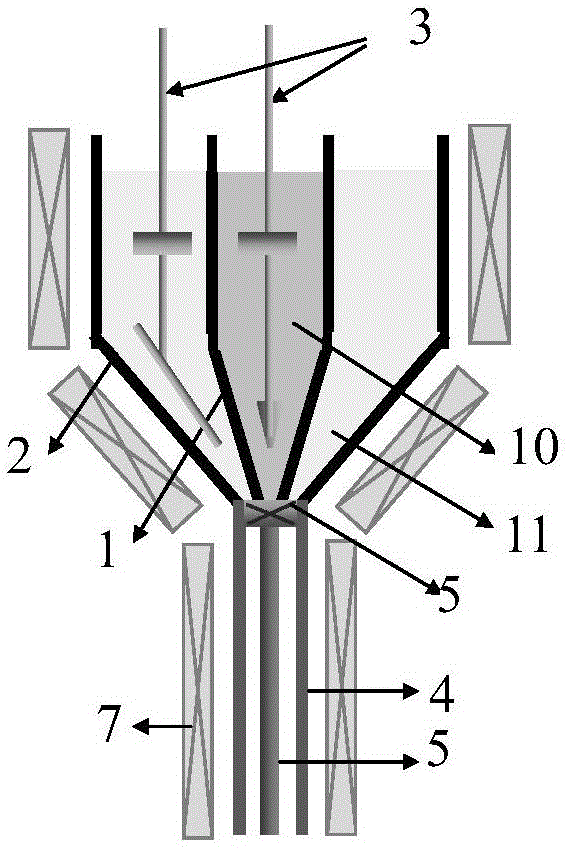

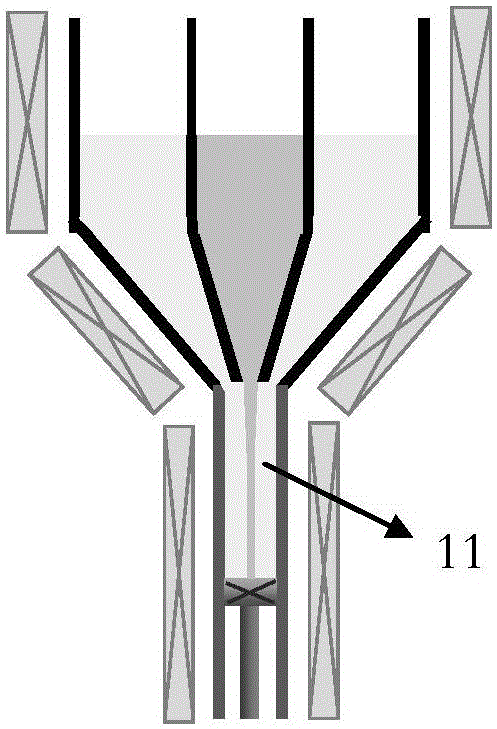

[0040] Such as Figure 1-2As shown, a soft glass optical fiber preform manufacturing device based on double-crucible laminar flow leak injection includes a coaxial inner crucible 1 and an outer crucible 2, and the outer crucible is longer than the inner crucible so as to be able to seal the After the inner crucible is completely surrounded, a stirring device 3 is respectively arranged in the inner crucible 1 and the outer crucible 2, and the lower part of the inner crucible 1 has an outlet communicating with the mold 4, and the mold 4 has a built-in piston and its electric drive mechanism 5, the inner crucible 1 and the outer crucible 2 are placed in the high-temperature furnace 6, the mold 4 is placed in the heating element 7, and the mold 4 and the electric drive mechanism 5 are placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com