Process and apparatus for controlling continuous and stable discharge of non-condensable gas in benzene recovery system

A recovery system and condensing technology, which is applied in the field of process and device to control the continuous and stable discharge of non-condensable gas in the benzene recovery system, can solve problems such as difficult product quality assurance, poor discharge of non-condensable gas, safety accidents, etc. To achieve the effect of reasonable and compact equipment layout, elimination of unstable factors, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

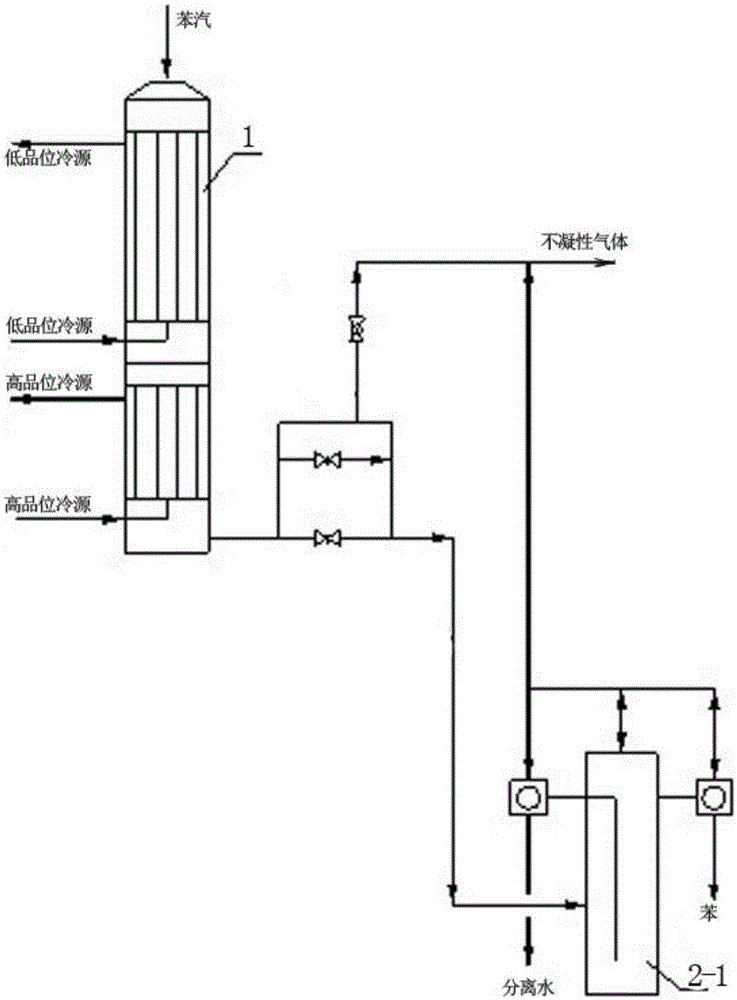

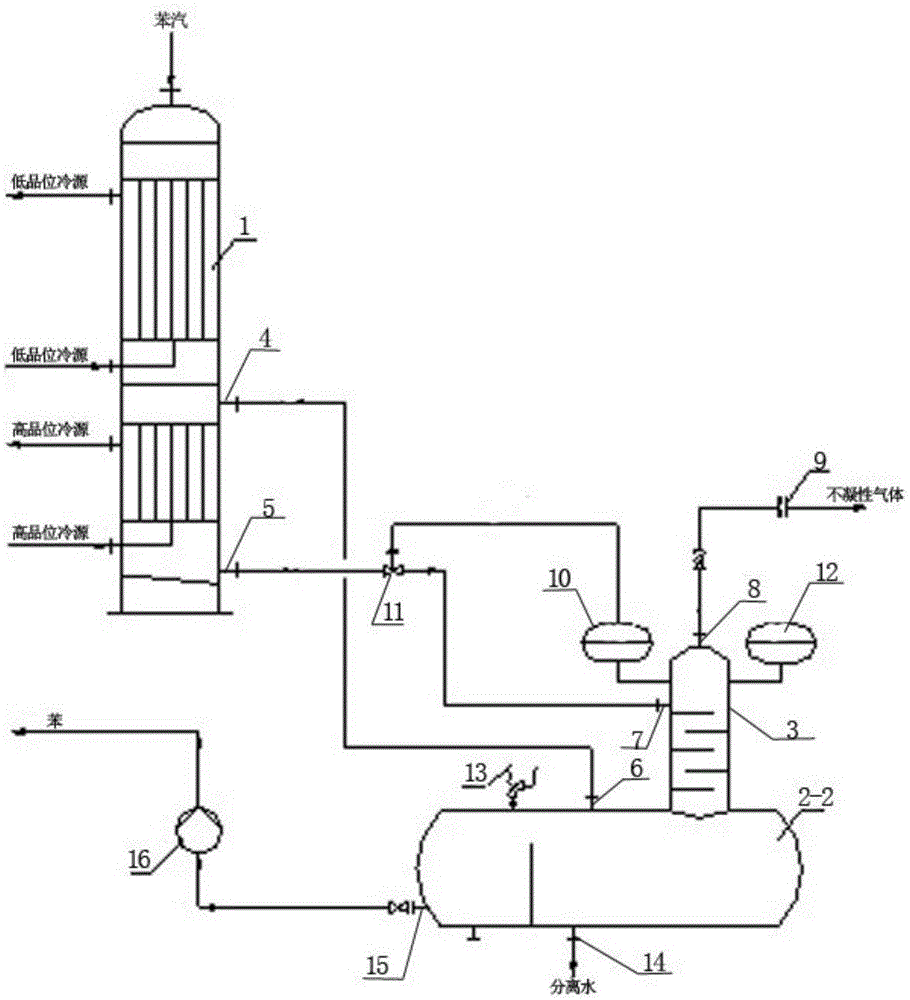

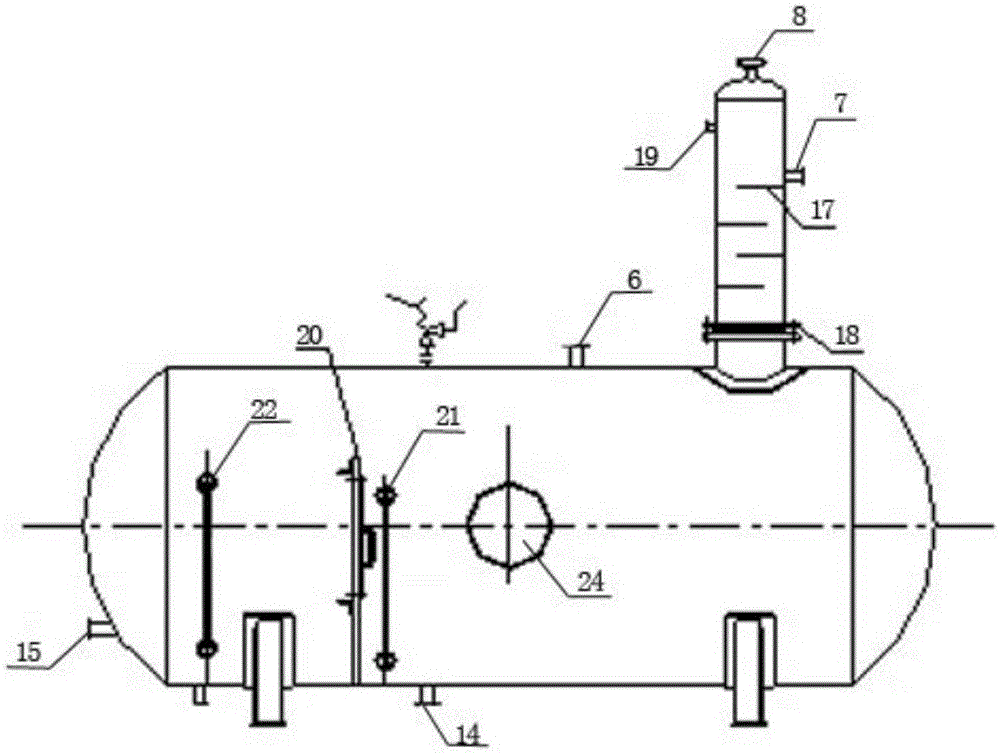

[0019] See figure 2 , is the flow chart of the process for controlling the continuous and stable discharge of non-condensable gas in the benzene recovery system of the present invention, the process for controlling the continuous and stable discharge of non-condensable gas in the benzene recovery system of the present invention, the benzene produced by the top of the benzene removal tower The steam enters the condensing cooler 1, and is cooled by a low-grade cold source and a high-grade cold source in sections to obtain a benzene-water mixture; the benzene-water mixture flows into the gas-liquid mass transfer heat transfer device 3 and flows to the lower benzene-water separator 2- 2 flow, the gas phase in the condensing cooler 1 enters the benzene-water separator 2-2 and flows into the upper gas-liquid mass transfer and heat transfer device 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com