Artificial plastic hinge at beam end of building concrete structure and construction method thereof

A technology of concrete structure and plastic hinge, which is applied in the direction of building structure and architecture, and can solve the problems that have not been widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

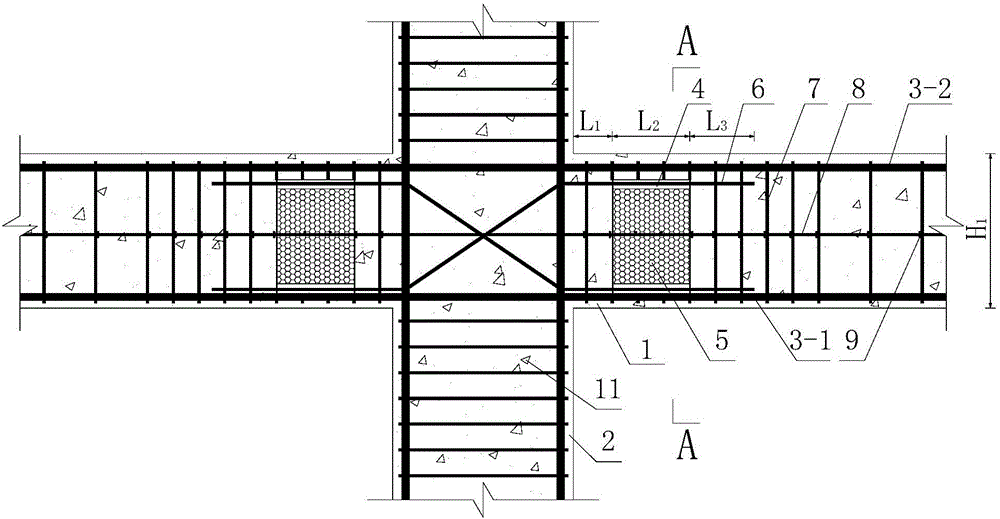

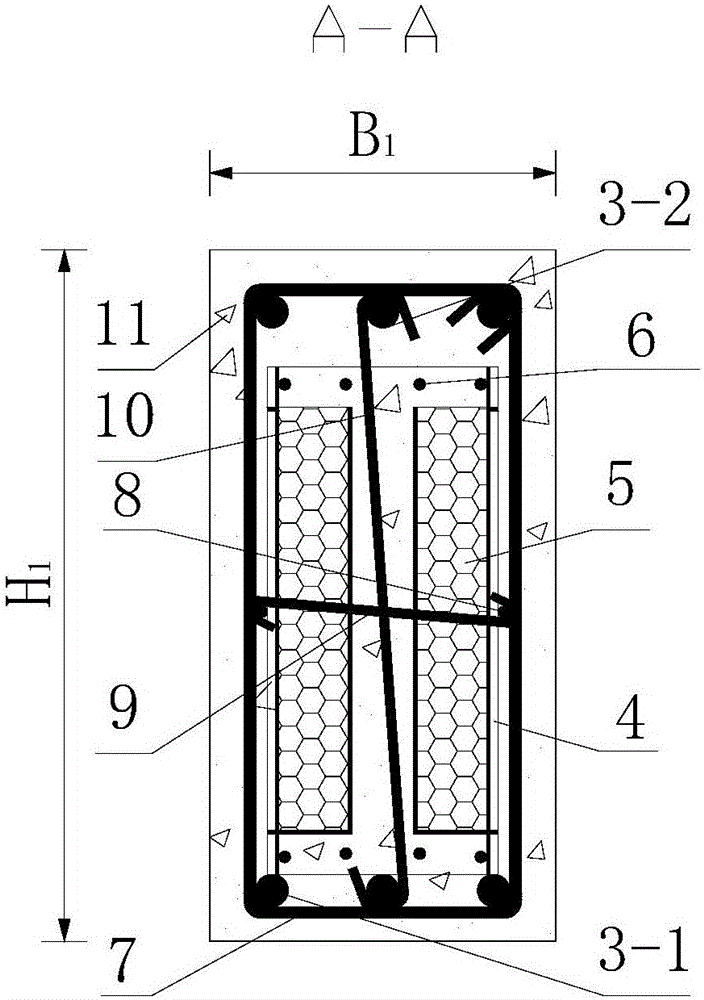

[0148] like figure 1 as well as Figure 3 ~ Figure 7 As shown, the artificial plastic hinge at the beam end of the building concrete structure of the present invention, the building concrete structure includes a beam 1 to be set and a column connected to the beam 1 to be set, and the beam 1 to be set is provided with a beam bottom longitudinal reinforcement 3- 1. Beam top longitudinal reinforcement 3-2, beam stirrup 7, beam waist reinforcement 8 and S-shaped stirrup 10, the artificial plastic hinge at the beam end includes a plastic hinge structure arranged at the end of the beam 1 to be installed and the column connected box 4, and the plastic hinge structural reinforcement 6 and tie reinforcement 9 for fixing the plastic hinge structural box 4; the plastic hinge structural box 4 is placed between the longitudinal reinforcement 3-1 at the bottom of the beam and the longitudinal reinforcement 3-2 at the top of the beam, so The number of the plastic hinge structural steel bars...

Embodiment 2

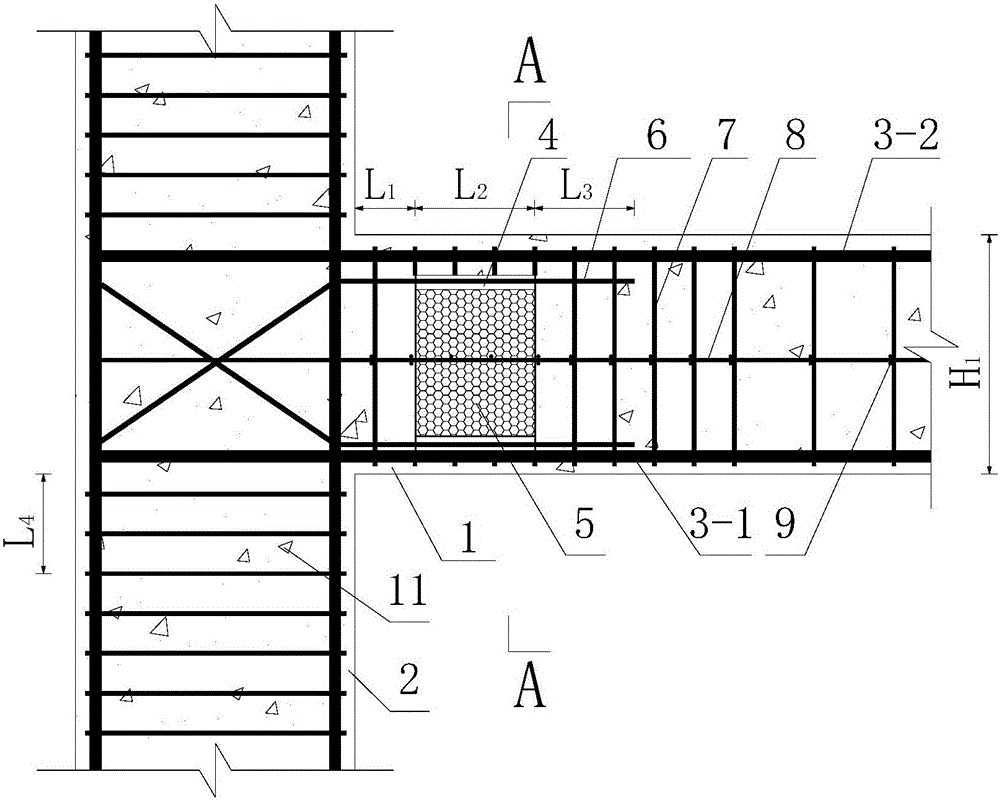

[0157] like figure 2 as well as Figure 3 ~ Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the column is a side column 2-2, the number of the plastic hinge construction box 4 is one, and one end of the plastic hinge construction steel bar 6 crossed in pairs Through the plastic hinge structure reinforcement hole 12 arranged on the plastic hinge structure box 4, the other end of the plastic hinge structure reinforcement 6 crossed in pairs stretches out from the connection node between the beam 1 to be set and the column and connects with the side column 2-2 rebar connections. All the other structures are the same as in Example 1.

[0158] During specific implementation, the plastic hinge structural reinforcement 6 extends out the length L of the beam 1 to be set. 4 is 250mm.

[0159] like Figure 8 As shown, the method for constructing the artificial plastic hinge at the beam end of the building concrete structure in embodiment 1 and emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com