A device and method for reducing shrinkage difference of concrete foundation

A concrete foundation and concrete layer technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of small contact area between resistance wire and concrete, increasing the risk of cracking of newly poured concrete, and high local temperature of the resistance wire. Achieve the effect of low realization difficulty, solving practical problems of quality control, and small transformation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

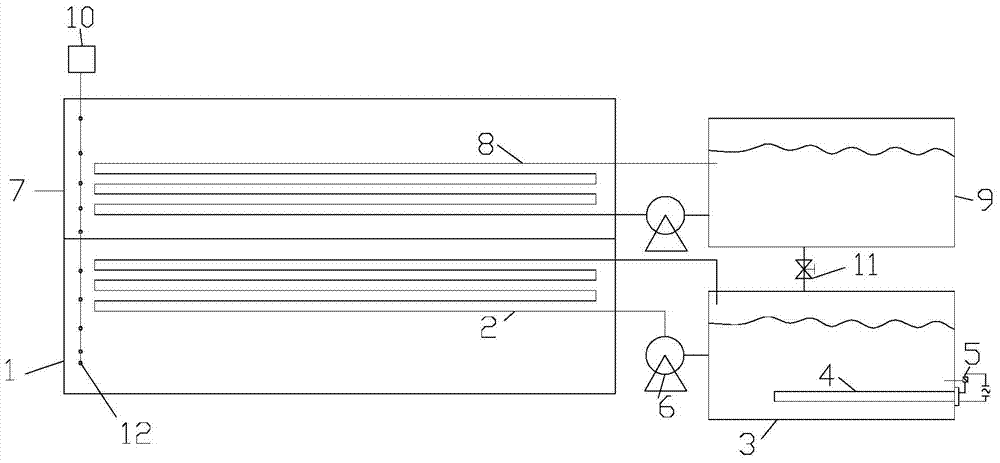

[0034] like figure 1 As shown, the embodiment of the present invention provides a device for reducing the shrinkage difference of the concrete foundation, including a first cooling water pipe 2 and a second cooling water pipe 8, both of which are serpentine pipes. Wherein, the first cooling water pipe 2 and the second cooling water pipe 8 are existing cooling water pipe systems in the prior art, which reduces the difficulty and cost of system implementation.

[0035] The first cooling water pipe 2 is connected with the hot water circulating water tank 3, the second cooling water pipe 8 is connected with the cold water circulating water tank 9, the first cooling water pipe 2 and the second cooling water pipe 8 are connected with the hot water circulating water tank 3 and the cold water circulation through the circulating water pump 6 respectively Water tank 9 is connected. The hot water circulating water tank 3 is communicated with the cold water circulating water tank 9 throu...

Embodiment 2

[0040] Embodiments of the present invention provide a method for reducing the shrinkage difference of concrete foundations, comprising the following steps:

[0041] S1. Concrete the lower concrete layer 1, pre-embed the first cooling water pipe 2 in the horizontal direction at the pouring front of the lower concrete layer 1, the number of the first cooling water pipe 2 is at least one, and the first cooling water pipes 2 are stacked on top of each other In the area between the surface of the lower concrete layer 1 and a certain depth, the certain depth is 0.2 times the transverse width of the concrete. It should be noted that this area is a strong confinement area. Then the temperature measuring element 12 is pre-embedded around the first cooling water pipe 2, and the temperature measuring element 12 is respectively arranged in the middle part of the vertical direction of the lower concrete layer 1, and the temperature measuring element 12 is used to monitor the internal maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com