Coal mine underground multi-stage energy-saving roadway cleaning device

A cleaning device and roadway technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as easy failure, failure to realize section cleaning, and many power lines and communication lines, so as to achieve improved safety performance and dust removal effect Good, radiation and wide coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

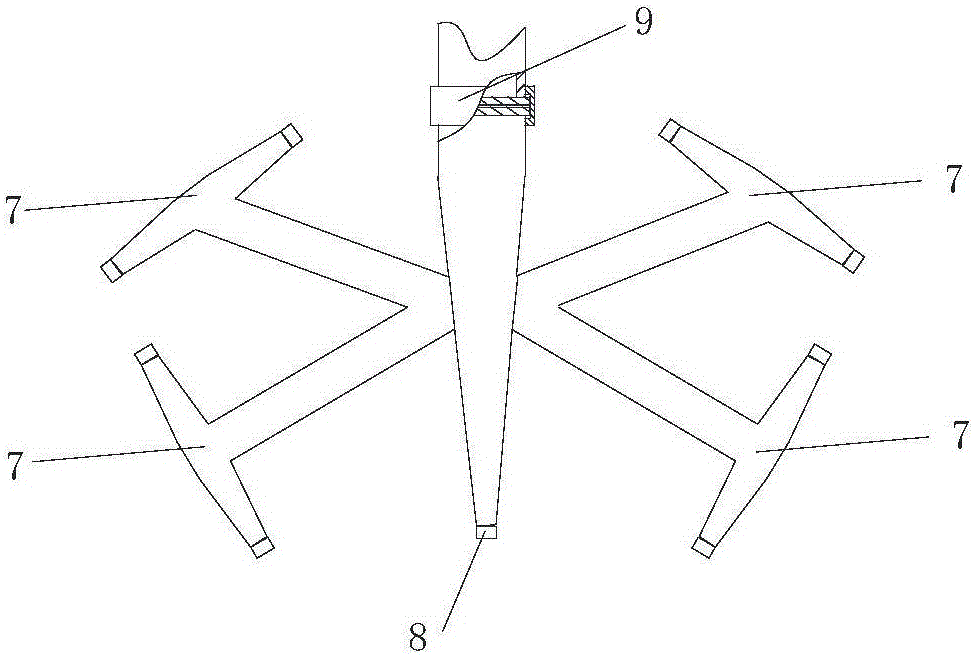

Method used

Image

Examples

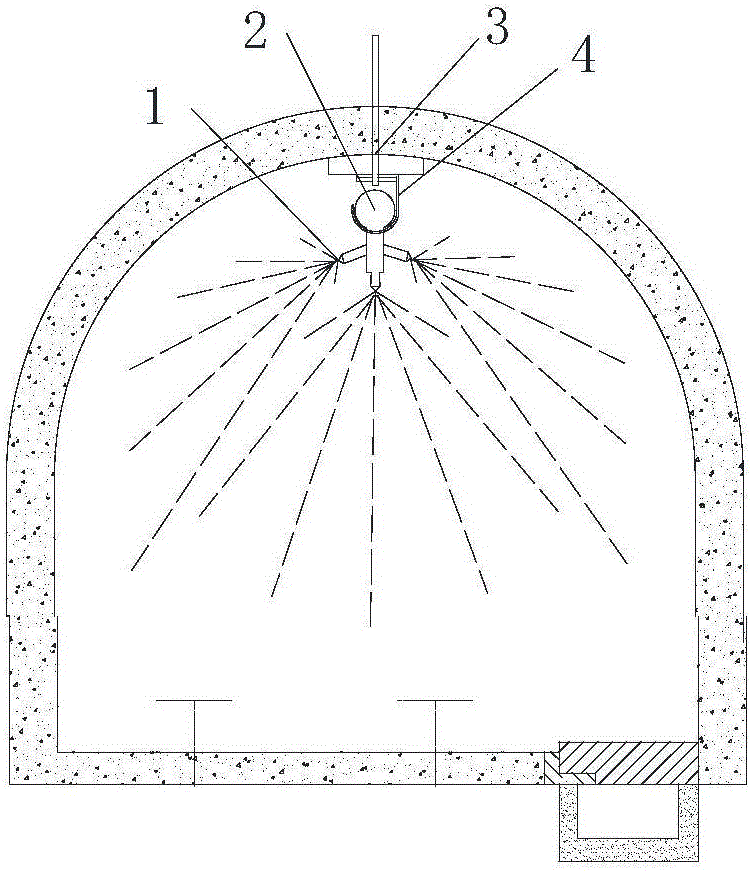

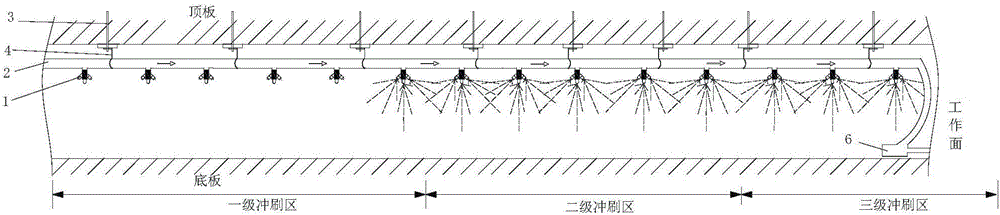

Embodiment 1

[0066] Taking the roadway with a length of 300m as an example, it is divided into three-level scour areas, with the working face as the origin, and the first 100m is the three-level cleaning area (the low-pressure water area is 1MPa, and the threshold value of all nozzles in this area is set below 1MPa);

[0067] 100-200m is the secondary cleaning area (medium pressure water area 2MPa, the threshold x of all nozzles in this area is set to: 1MPa<x<2MPa), 200-300m is the primary cleaning area (high pressure water area 3MPa, all nozzles in this area Set the threshold x as: 2MPa<x<3MPa).

[0068] Note: The set threshold and flushing levels can be adjusted appropriately according to different mine conditions.

[0069] At the beginning of roadway cleaning, first set the pressure of the high-pressure water pump to 1MPa, and the threshold of the nozzles in the third-level scour area near the working face is less than 1MPa, that is, the water pressure is greater than the threshold of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com