Steel strand connecting piece

A technology of steel strands and connectors, applied in the direction of transmission elements or ropes or cables for pulleys, textile cables, belts/chains/gears, etc. The effect of easy molding and mass production, high structural strength and large adjustment margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

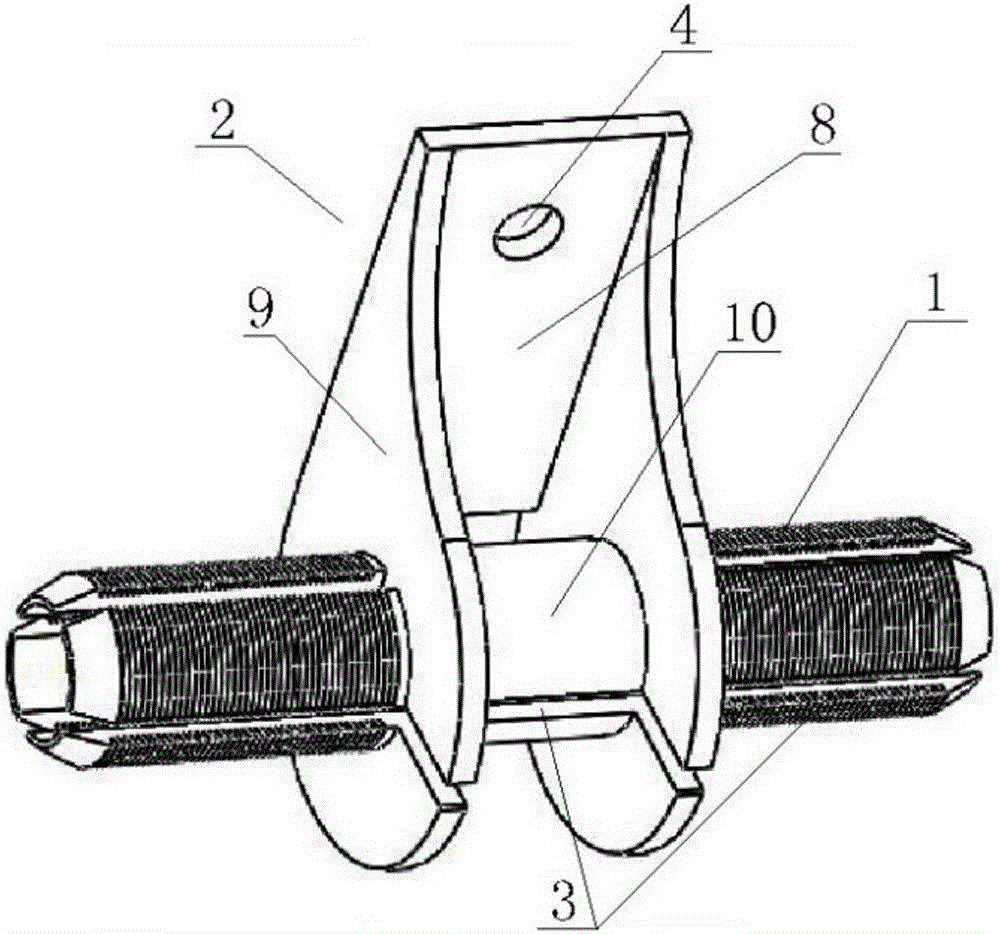

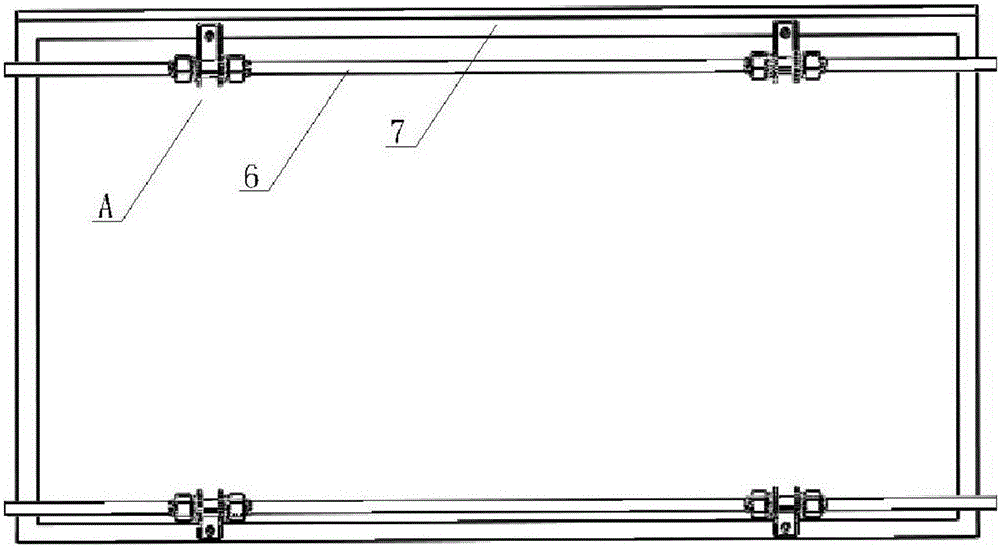

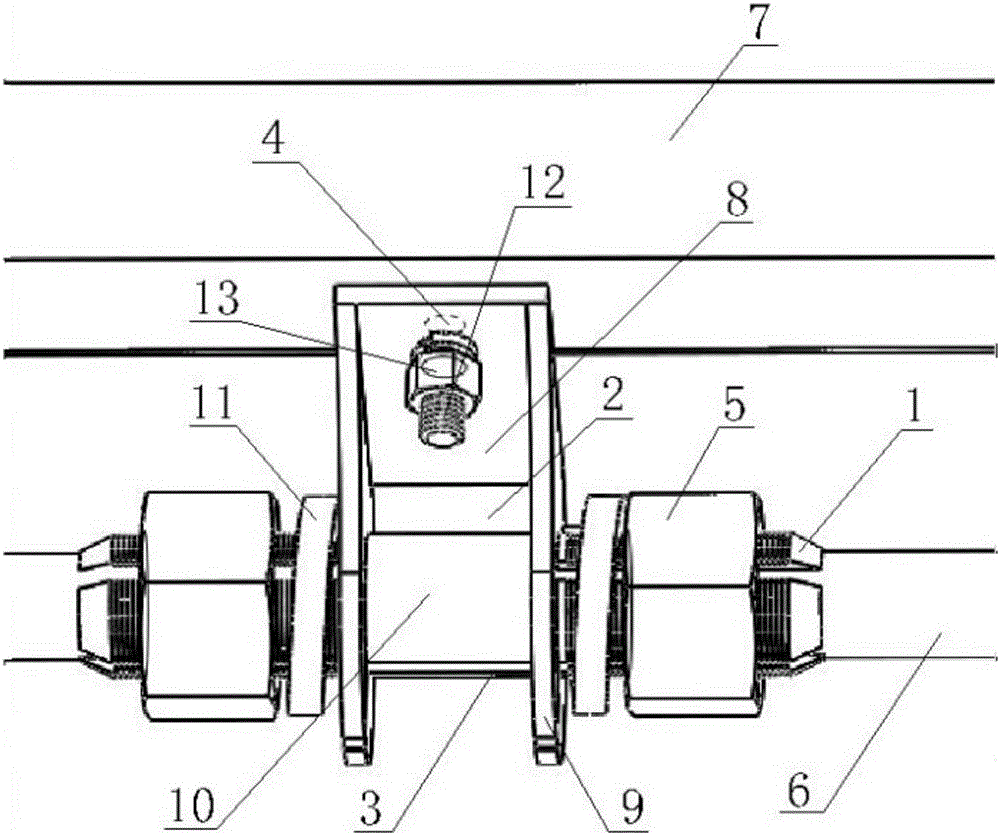

[0018] Such as Figure 1-3 As shown, a steel strand connector provided by the present invention includes a connecting platform 2 and two expansion pipes 1 oppositely arranged.

[0019] The connecting platform 2 has a "6"-shaped structure, including a rectangular fixed plate 8, two "6"-shaped baffles 9 oppositely arranged on both sides of the fixed plate 8, and a through pipe 10 located between the two baffles 9, the through pipe The two ends of 10 are respectively connected to the inner sides of the two baffles 9. This structure can disperse the load on the platform during the downward transmission process, reduce stress concentration, and ensure that the platform can bear a relatively large load. There is a connection hole 4 on the fixing plate 8, and an adjustment seam 3 is opened on the bottom of the two "6"-shaped baffles 9 and the through pipe 10, so that the steel strand connector can be adjusted according to the thickness of the steel strand. Facilitates the sliding of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com