Universal lamp

A lamp and lamp housing technology, applied in the field of general lamps, can solve problems such as failure to match market demand, increase in production costs, unfavorable production arrangements, etc., and achieve the effects of facilitating market changes, stable income, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

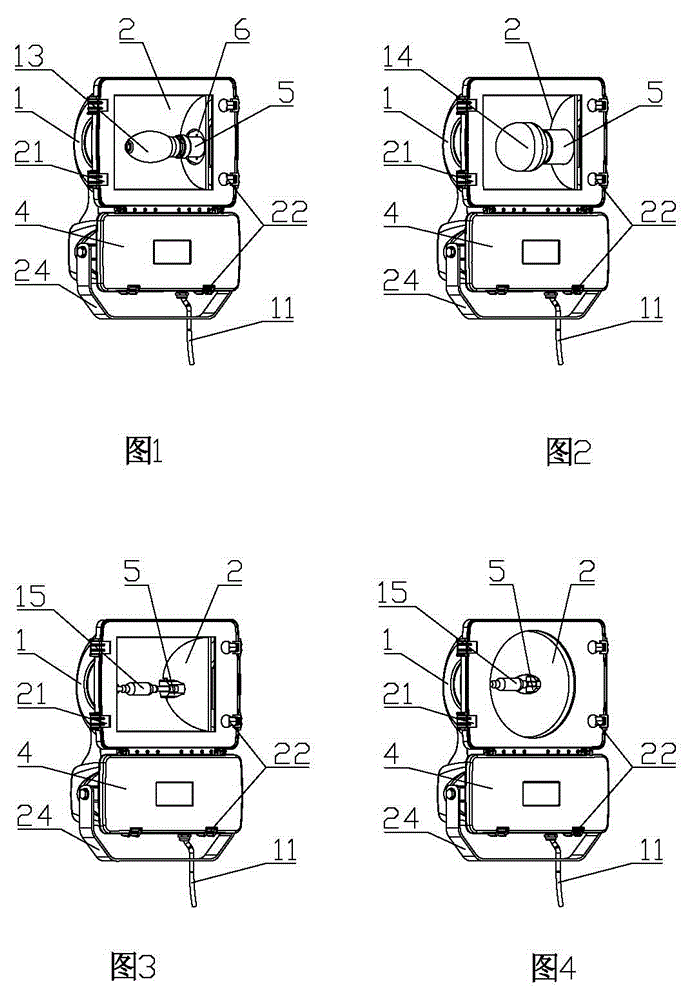

[0025] Embodiment one: as attached figure 1 As shown, the light source is a single-ended metal halide light source 13 .

Embodiment 2

[0026] Embodiment two: as attached figure 2 As shown, the luminescent light source is an electrodeless light source 14 .

Embodiment 3

[0027] Embodiment three: as attached image 3 , 4 As shown, the light source is a double-ended metal halide light source 15 .

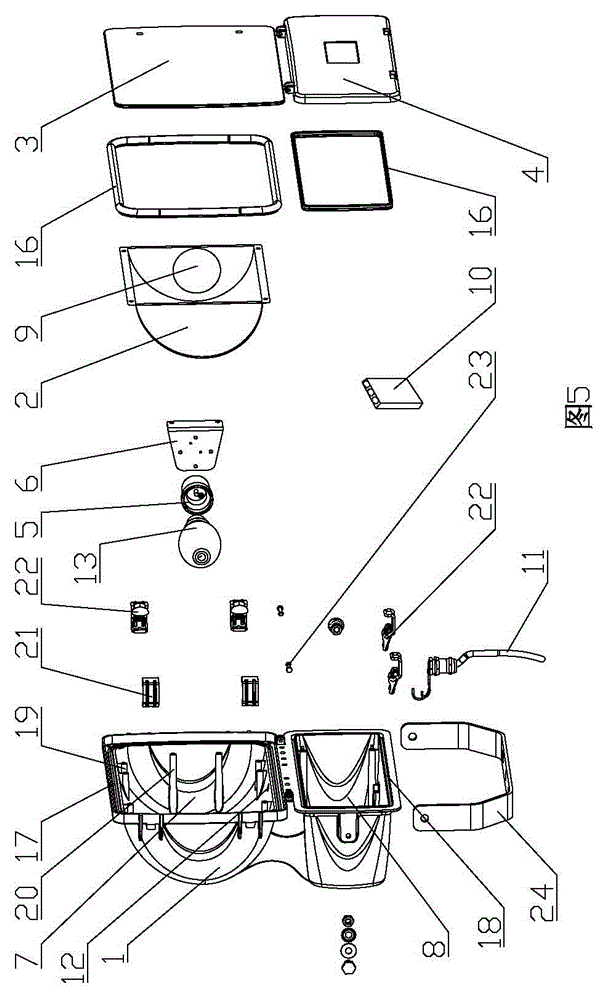

[0028] as attached figure 1 , 2 , 3, 4, and 5, a sealing strip 16 is provided between the light source opening and the light-transmitting sealing plate 3 and between the accessory opening and the accessory sealing plate 4. In this way, a good seal can be formed to prevent dust, water mist, etc. from entering the light source cavity 7 or / and the accessories cavity 8 .

[0029] as attached figure 1 , 2 , 3, 4, and 5, the light source opening and the accessory opening are respectively provided with a light source sealing groove 17 and an accessory sealing groove 18, and a sealing strip 16 is installed in the light source sealing groove 17 and the accessory sealing groove 18 and passes through the corresponding transparent groove respectively. The optical sealing plate 3 or the accessories sealing plate 4 limit the position. In this way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com