Automobile water collecting tank reinforcing plate checking fixture

A gutter and reinforcement plate technology, applied in the field of inspection tools, can solve problems such as inconvenient maintenance of inspection tools, cumbersome processing technology, and heavy handling of inspection tools, and achieve the goals of improving product market competitiveness, simplifying processing technology, and shortening the development cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

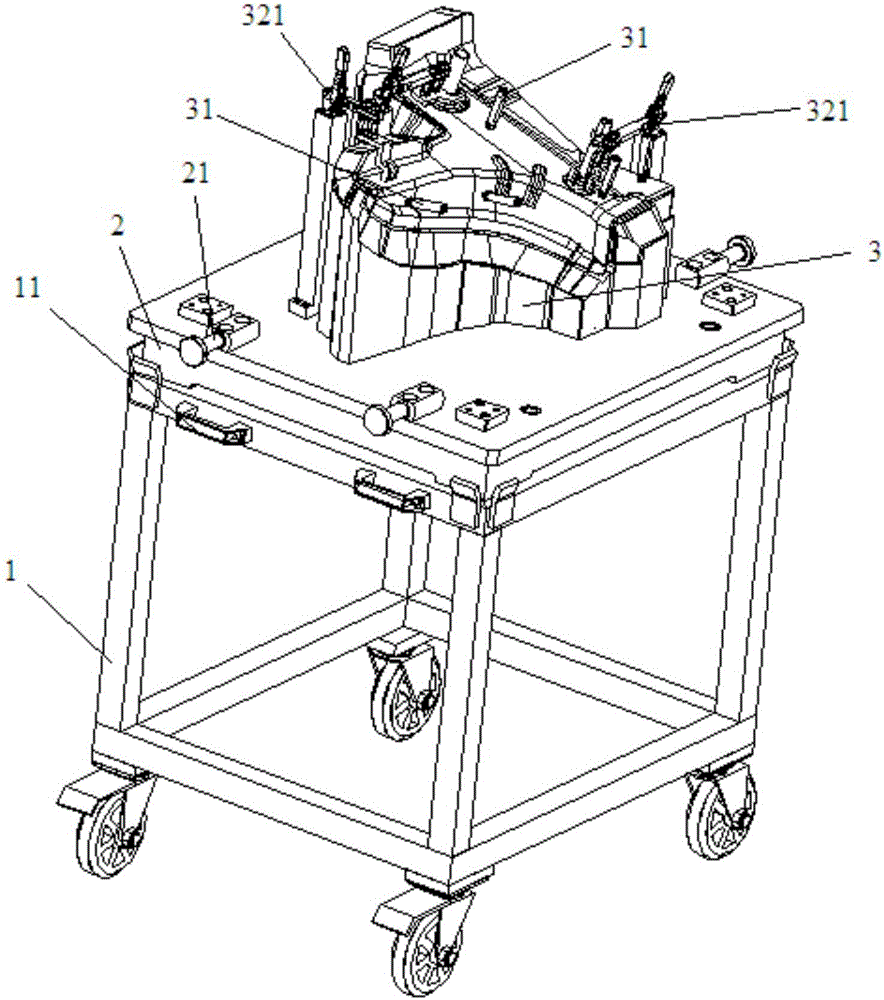

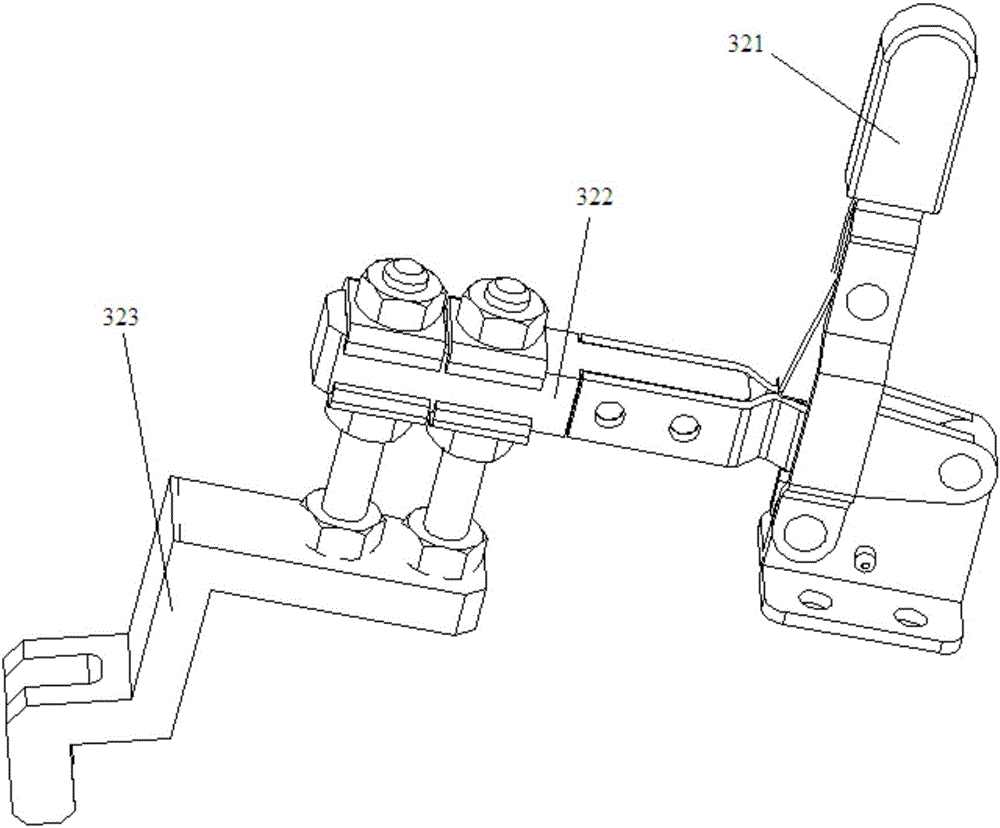

[0022] Such as figure 1 As shown in the figure, a checker for the reinforced plate of the automobile gutter is used to detect whether the position, size, trimming size and profile of the holes on the reinforced plate of the automobile gutter are qualified. The checker includes a wheel frame 1, a mounting seat 2 and The main body 3 and the mounting seat 2 are arranged on the wheel frame 1 and fixed by pivot pins. The main body 3 of the inspection tool is fixed on the installation seat 2. The main body 3 of the inspection tool is provided with a plurality of hole detection pins 31 and hole detection holes. And the clamping assembly, the surface shape of the main body 3 of the inspection tool is the same as the shape of the automobile gutter reinforcement plate, the positions of the hole position detection pin 31 and the hole detection hole are the same as the positions of the holes on the automobile gutter reinforcement plate, and the wheel frame 1 Hanging lugs 11 are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com