Optical fiber gas concentration detection method with temperature compensation capacity

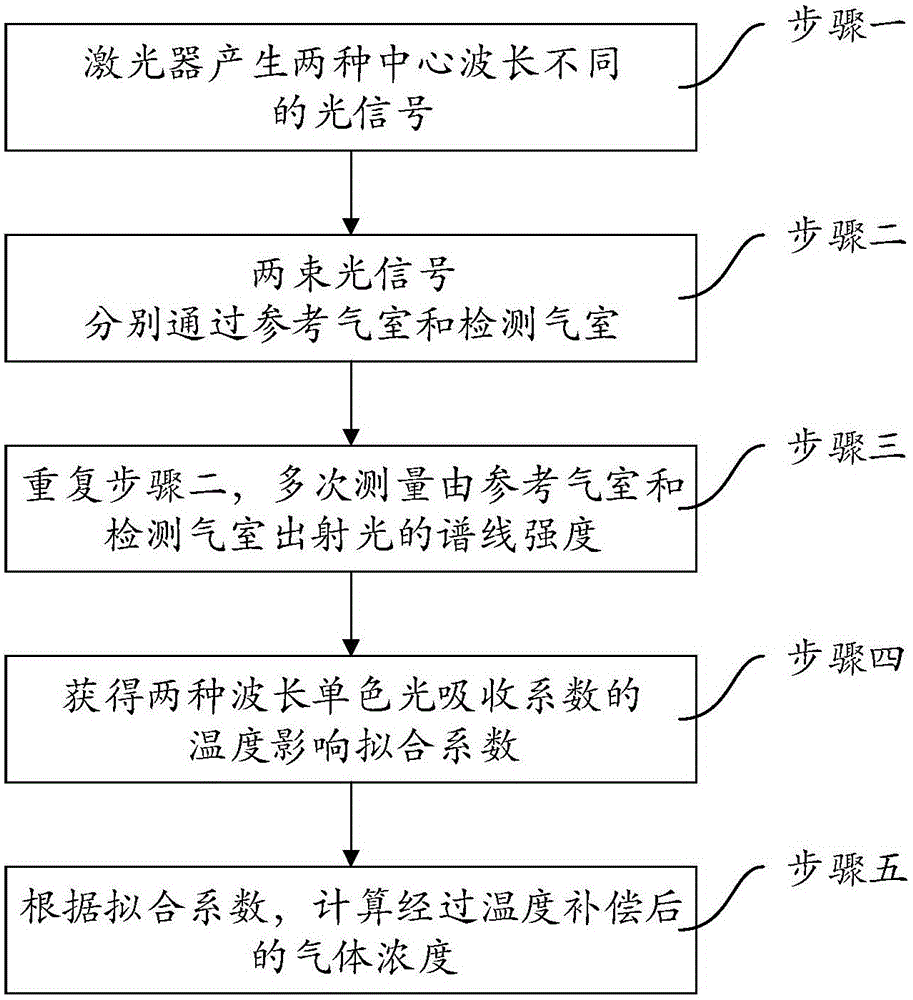

A technology for gas concentration detection and temperature compensation, which is used in the measurement of color/spectral characteristics to improve detection accuracy and reduce measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

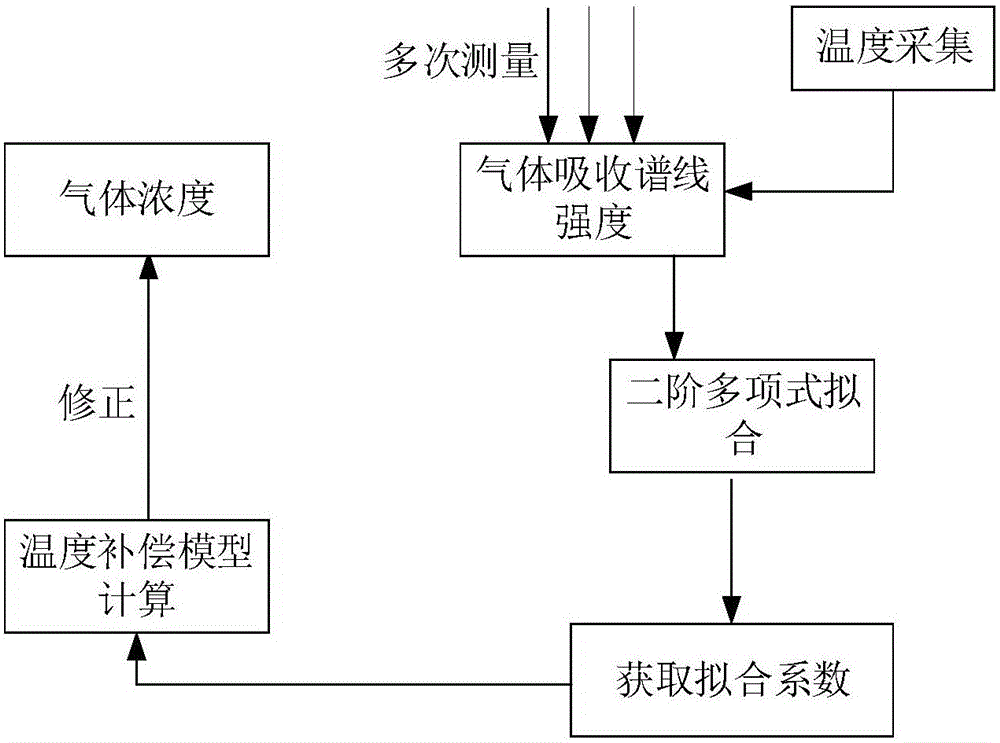

Method used

Image

Examples

example

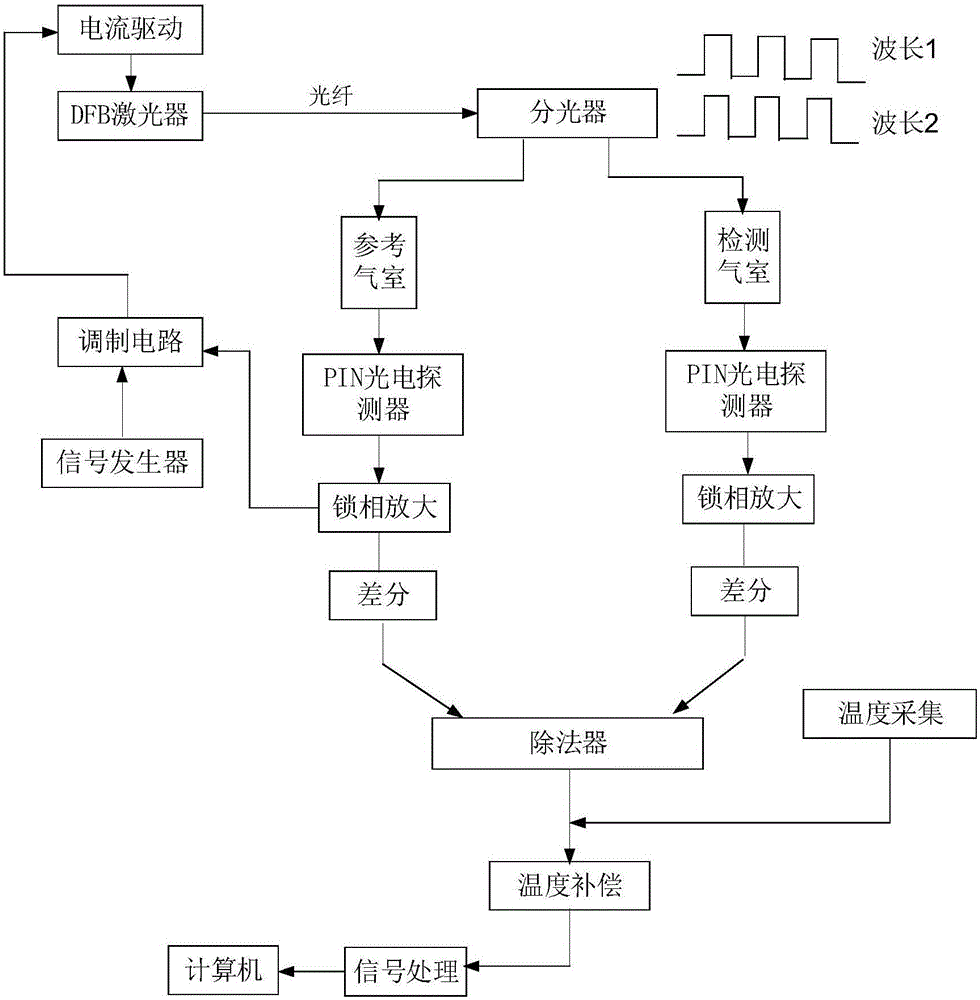

[0072] Differential absorption detection systems based on existing two-electrode DFBLD, such as figure 2 As shown, the signal generator generates a sine wave, and its output wavelength is modulated by adjusting the injection current of the laser. By changing the current ratio input by the two electrodes of the semiconductor laser, two optical signals with center wavelengths λ1 and λ2 are generated, λ2 is the reference light, and λ1 corresponds to the absorption peak of gas molecules, and the intensity is approximately equal. The light emitted from the DFBLD passes through the optical isolator to the fiber coupler, and the light coupled into the fiber is divided into two beams by the beam splitter. One beam of light passes through the reference gas chamber to the PIN detector, and the PIN output signal is phase-locked and amplified. It is used to feed back the injection current of the laser and stabilize the output frequency of the laser; another beam of light passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com