Screw drive electrode adjustable water resistor

A screw drive and adjustable technology, applied in the direction of liquid resistors, etc., can solve problems such as difficulty in replacement, achieve the effects of reducing use costs, easy operation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

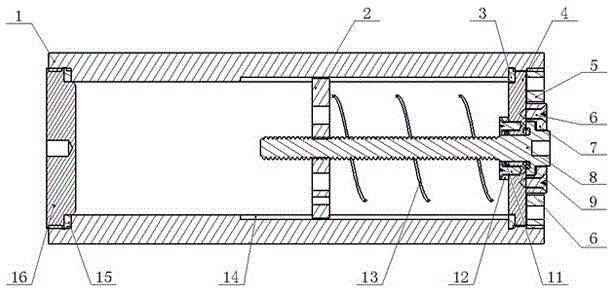

[0018] Such as figure 1 As shown, a screw-driven electrode adjustable water resistor includes a resistor body 1, and the two ends of the resistor body 1 are respectively closed by an input electrode plate 16 and an output electrode sealing plate 4 to form a closed cavity, and the cavity is filled with Electrolyte solution, resistor body 1 selects a plexiglass cylinder with a certain thickness, and two square chute 14 are symmetrically processed from the rear end of the inner wall of the resistor body to the front end, and the two square chute 14 form a group. According to actual needs, A plurality of chutes 14 can also be set, and a mobile electrode plate 2 is placed in the chute 14. The mobile electrode plate 2 is made of red copper. Its external shape is adapted to the inside of the resistor body 1, and a There is a protruding slider matching the chute 14, and a plum blossom-shaped through hole is set on the mobile electrode plate 2, wherein the central through hole is a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com