A method of overcurrent protection for small-capacity bus capacitor drivers

A bus capacitor and overcurrent protection technology, applied in emergency protection circuit devices, electronic commutation motor control, single motor speed/torque control, etc., can solve the problem of small drives, can not protect the bus capacitor capacity, can not protect the driver safety, etc. problem, to achieve the effect of simple algorithm implementation, high reliability, and elimination of voltage pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

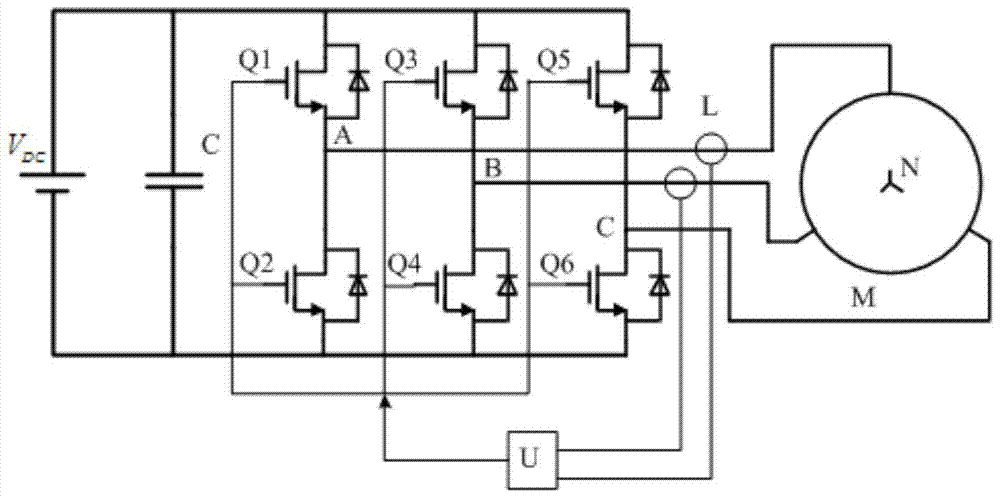

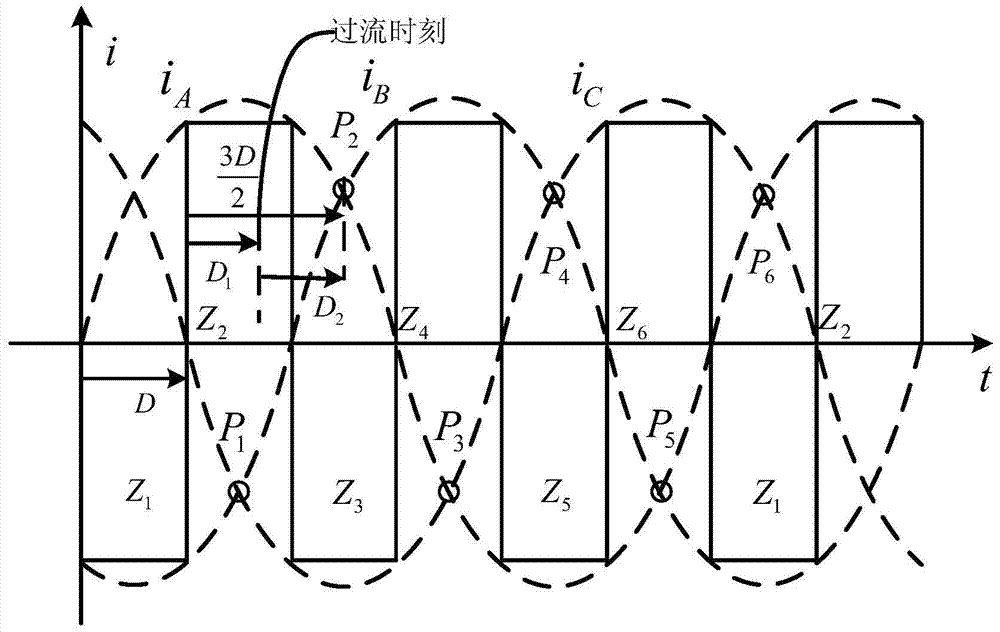

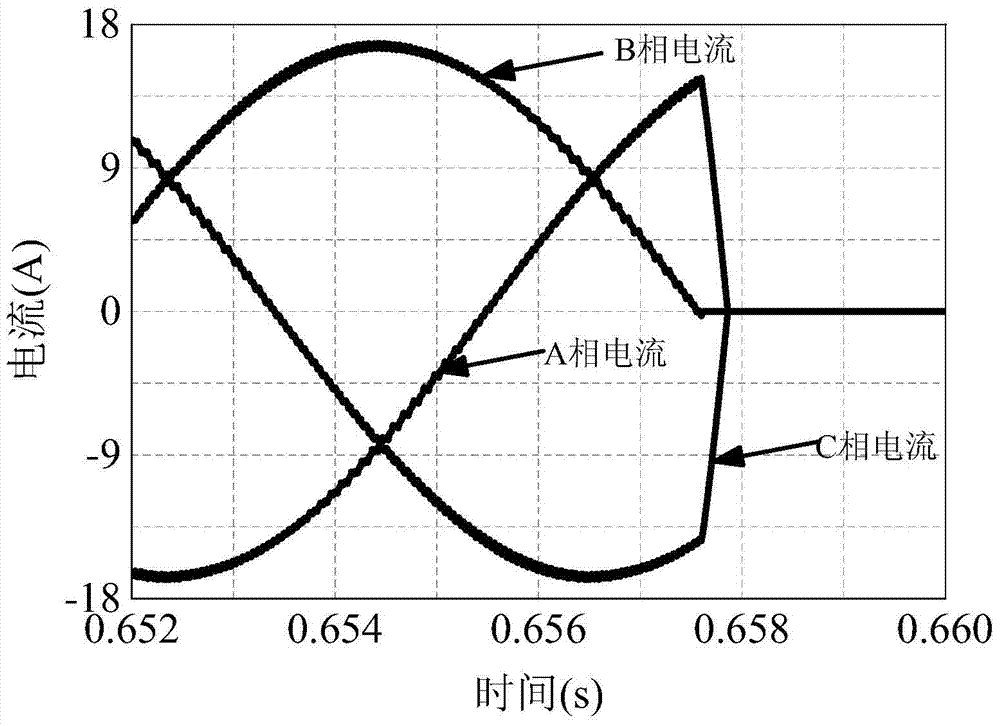

[0024] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, its method steps are:

[0025] Step 1: When the permanent magnet synchronous motor M is running normally, the microcontroller U detects and records the time when any two phase currents are adjacent to the zero crossing point through its internal counter in real time, and this time is denoted by D; the starting time of timing is a certain phase At the zero crossing point of the current, the counter is cleared to zero at the next phase current zero crossing point, and the timing is restarted;

[0026] Step 2: When the permanent magnet synchronous motor M has an overcurrent or needs to be shut down in an emergency, the microcontroller U detects the current status of the three phases A, B, and C through the current sensor L, and controls the switch tubes Q1, Q2, Q3, Q4, The switching states of Q5 and Q6, namely:

[0027] When the A-phase current is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com