Overcurrent protection method of PMSM driver

A permanent magnet synchronous motor, overcurrent protection technology, applied in emergency protection circuit devices, electronic commutation motor control, single motor speed/torque control, etc. capacity and other issues, to achieve high reliability, simple algorithm implementation, and eliminate the effect of voltage pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

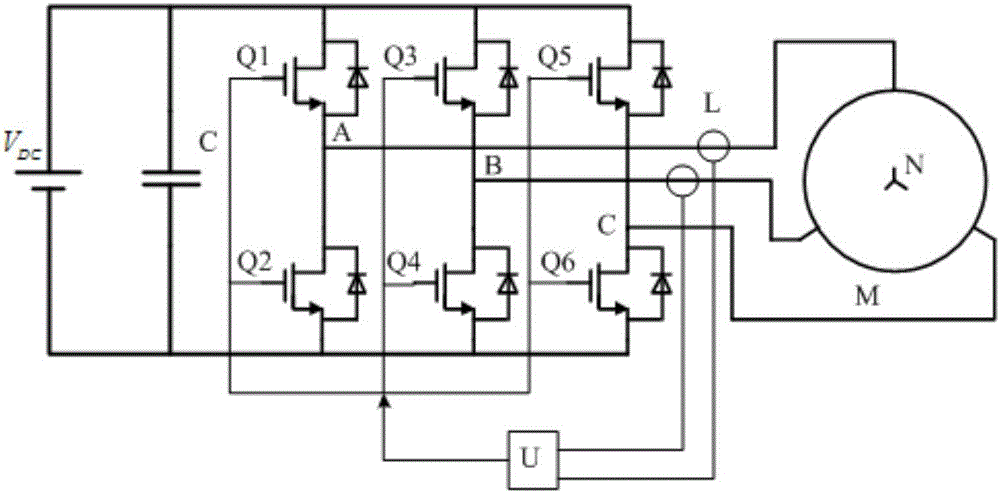

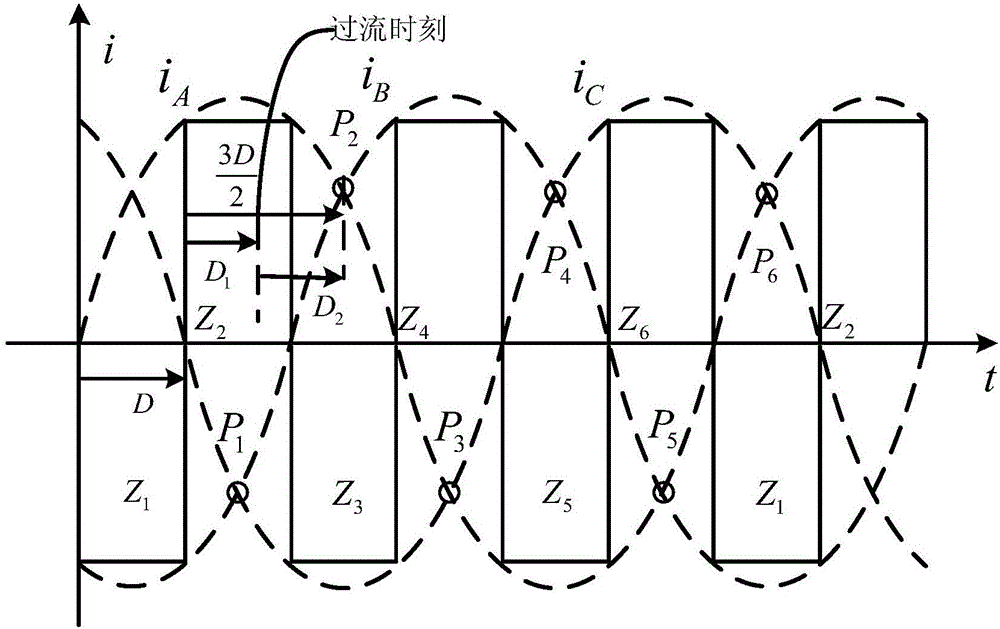

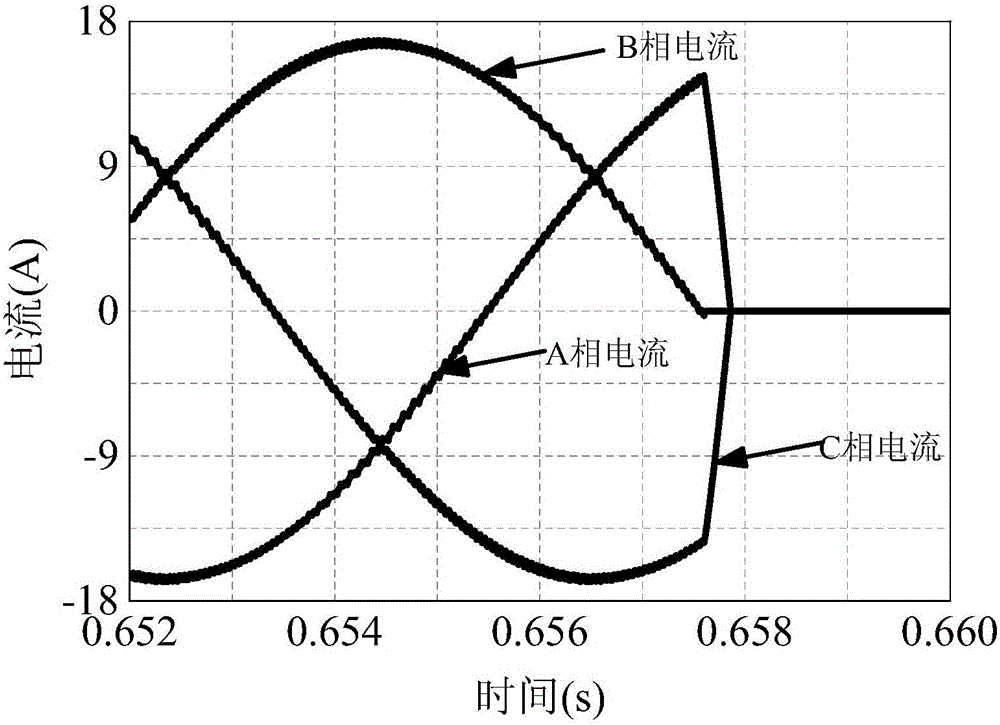

[0024] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, its method steps are:

[0025] Step 1: When the permanent magnet synchronous motor M is running normally, the microcontroller U detects and records the time when any two phase currents are adjacent to the zero crossing point through its internal counter in real time, and this time is denoted by D; the starting time of timing is a certain phase At the zero crossing point of the current, the counter is cleared to zero at the next phase current zero crossing point, and the timing is restarted;

[0026] Step 2: When the permanent magnet synchronous motor M has an overcurrent or needs to be shut down in an emergency, the microcontroller U detects the current status of the three phases A, B, and C through the current sensor L, and controls the switch tubes Q1, Q2, Q3, Q4, The switching states of Q5 and Q6, namely:

[0027] When the A-phase current is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com