Rubber composition for heavy load pneumatic tire

A technology of rubber composition and pneumatic tires, applied in the direction of heavy-duty tires, special tires, tire parts, etc., can solve the problems of insufficient durability and insufficient effect of reducing rolling resistance, and achieve the improvement of tire durability and reduction Effects of rolling resistance and fuel efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

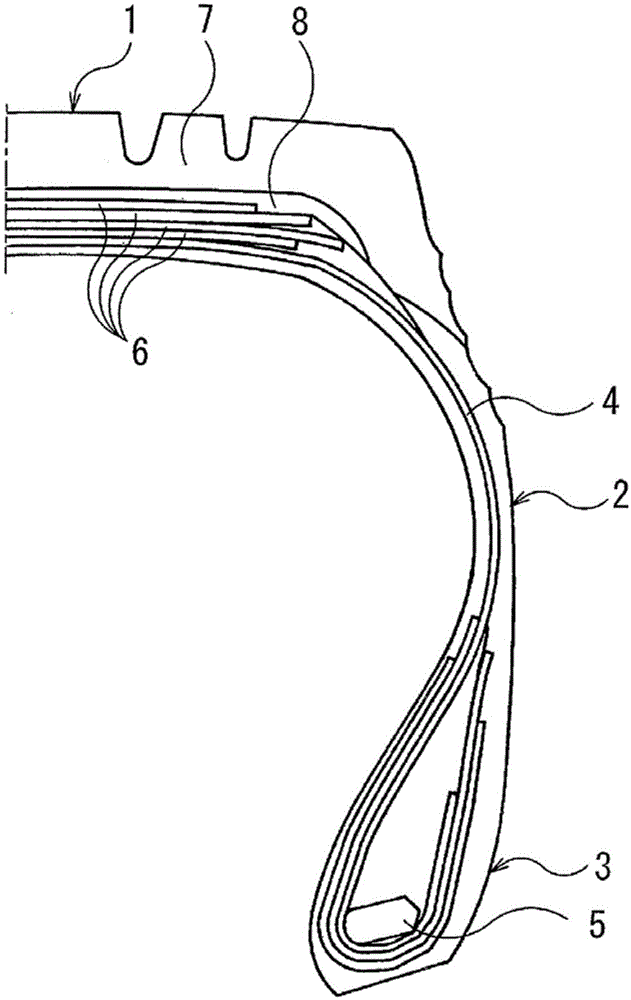

Image

Examples

Embodiment

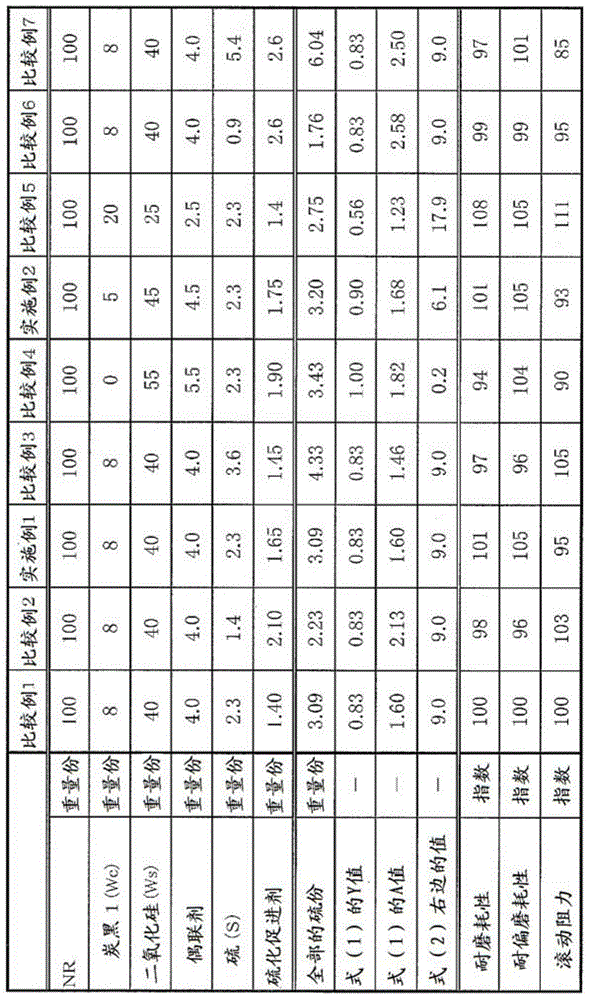

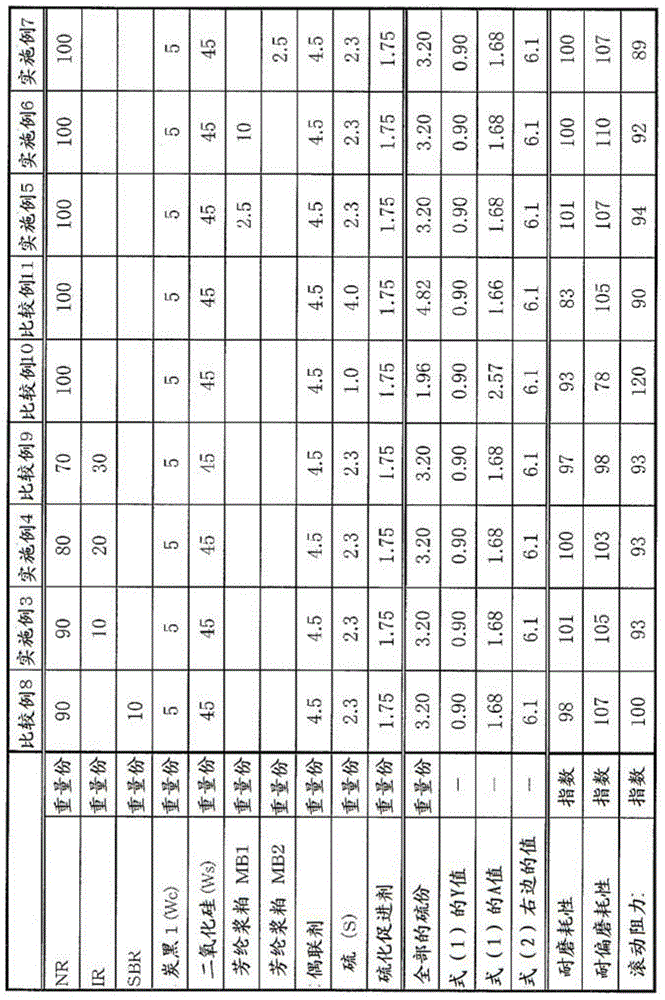

[0074] Using the compounding ingredients shown in Table 3 as a common compound, 18 kinds of rubber compositions for pneumatic truck tires (Examples 1-7, Comparative Examples 1-11) containing the compounds shown in Tables 1 and 2 were prepared in the following manner: Components other than sulfur and vulcanization accelerator were kneaded in a 1.8L closed mixer at 160°C for 5 minutes, then sulfur and vulcanization accelerator were added to the discharged masterbatch and kneaded with an open mixer. The total of sulfur and sulfur in the sulfur-containing silane coupling agent is shown in the column of "total sulfur content" in Tables 1 and 2. In addition, the addition amount of the common compounding agent described in Table 3 is shown by weight with respect to 100 weight part of diene-type rubbers described in Table 1, 2 (100 weight part of the net amount of rubber).

[0075] The obtained 18 types of rubber compositions for pneumatic truck tires were used in the crown tread port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com