Cleaning compositions containing a polyetheramine

A technology of cleaning composition and polyetheramine, applied in the field of cleaning composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

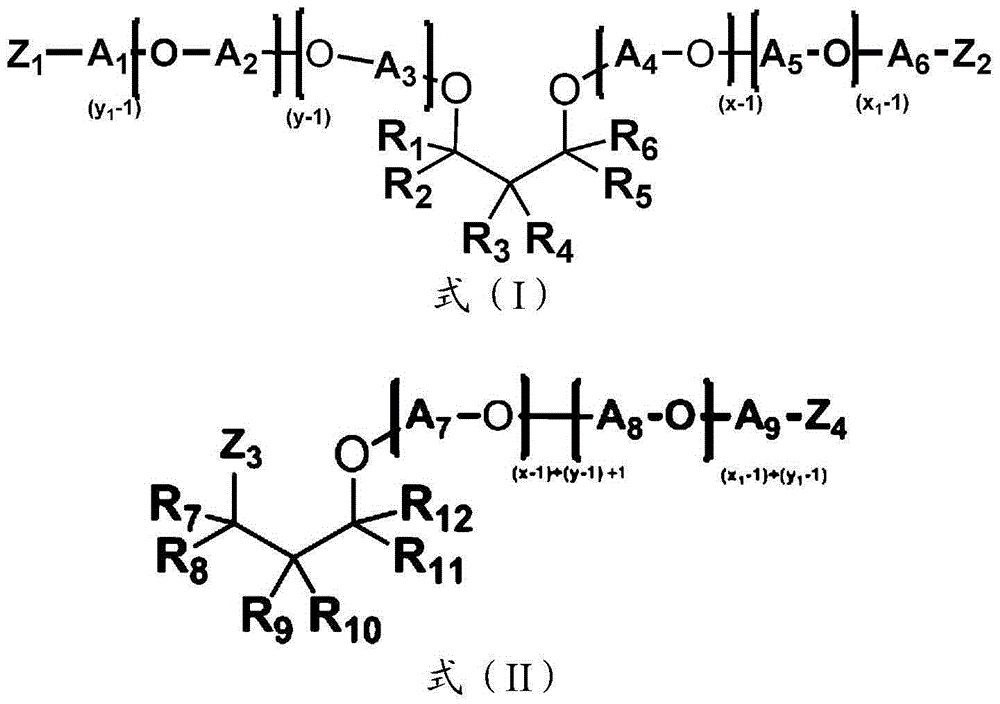

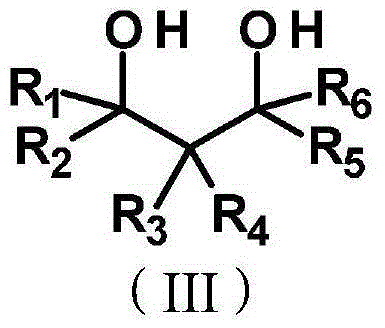

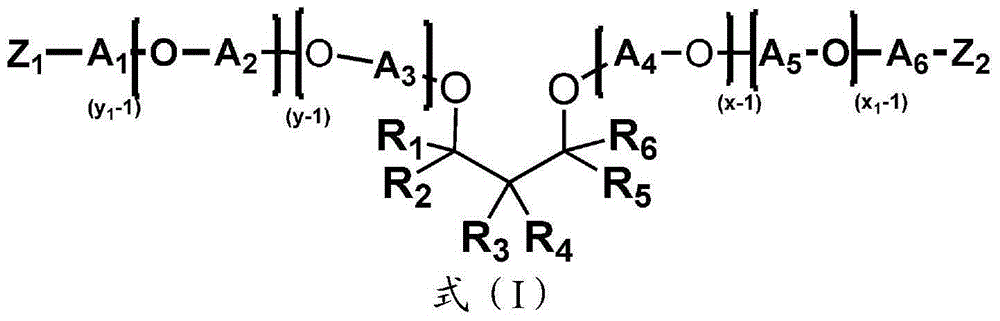

Method used

Image

Examples

example

[0300] In the following examples, the individual ingredients in the cleaning compositions are expressed as percentages by weight of the cleaning composition.

example 1

[0303] 1mol 2-butyl-2-ethyl-1,3-propanediol + 4mol propylene oxide / OH, aminated

[0304] a) 1mol 2-butyl-2-ethyl-1,3-propanediol + 4mol propylene oxide / OH

[0305]In a 2 l autoclave, 322.6 g of 2-butyl-2-ethyl-1,3-propanediol and 7.9 g of KOH (50% in water) were mixed and stirred at 120° C. for 2 h under vacuum (<10 mbar). The autoclave was purged with nitrogen and heated to 140°C. 467.8 g of propylene oxide were added in portions within 6 h. To complete the reaction, the mixture was post-reacted for an additional 5 h at 140°C. The reaction mixture was sparged with nitrogen, and volatile compounds were removed in vacuo at 80 °C. The catalyst potassium hydroxide was removed by adding 2.3 g of synthetic magnesium silicate (Macrosorb MP5plus, Ineos Silicas Ltd.), stirring at 100° C. for 2 h and filtering. A light yellow oil (772.0 g, hydroxyl value: 248.5 mgKOH / g) was obtained.

[0306] b) 1mol 2-butyl-2-ethyl-1,3-propanediol + 4mol propylene oxide / OH, aminated

[030...

example 2

[0311] 1mol 2,2,4-trimethyl-1,3-propanediol + 4mol propylene oxide, aminated

[0312] a) 1mol2,2,4-trimethyl-1,3-propanediol+4mol propylene oxide

[0313] 327.3 g of molten 2,2,4-trimethyl-1,3-propanediol and 8.5 g of KOH (50% in water) were dehydrated for 2 h in a 2 l autoclave at 80° C. and <10 mbar. The autoclave was purged with nitrogen and heated to 140°C. 519.4 g of propylene oxide were added in portions within 6 h. To complete the reaction, the mixture was post-reacted for an additional 5 h at 140°C. The reaction mixture was sparged with nitrogen, and volatile compounds were removed in vacuo at 80 °C. The catalyst was removed by adding 2.5 g Macrosorb MP5plus, stirring at 100° C. for 2 h and filtering. A light yellow oil (825.0 g, hydroxyl value: 172.3 mgKOH / g) was obtained.

[0314] b) 1mol 2,2,4-trimethyl-1,3-propanediol + 4mol propylene oxide, aminated

[0315] In a 9 l autoclave, 700 g of the diol mixture obtained from example 2-a, 1000 mL THF and 1500 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap