Method for inhibiting peanut aspergillus flavus pollution by perillaldehyde-sodium alginate composite coating

A technology of sodium alginate and perillaldehyde, which is applied in the direction of preserving seeds with a coating protective layer, and can solve the problem of no perillaldehyde.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 40ul of food additive perillaldehyde to 100g of peanut kernels, mix well in a closed container, put it into an ultrasonic processor for ultrasonic treatment, the ultrasonic frequency is 60kHz, the ultrasonic power is 120W, the ultrasonic temperature is 30°C, and the ultrasonic time is 30min .

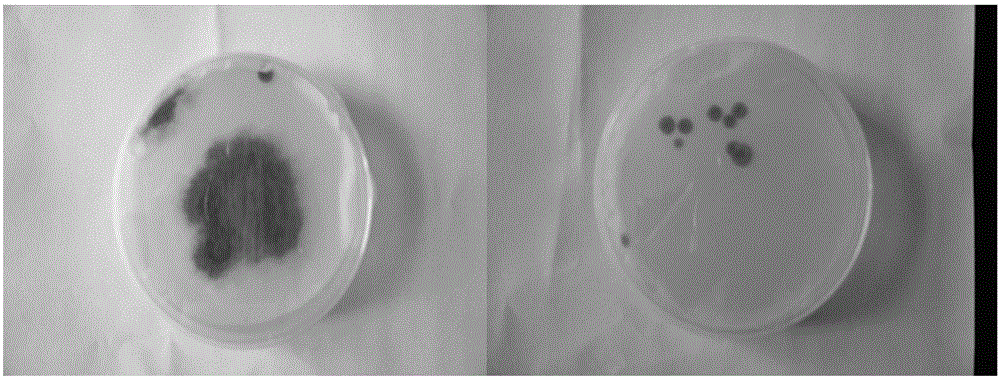

[0022] Add 100 g of peanut kernels and 40 ml of 0.2% sodium alginate coating liquid that have been ultrasonically treated with perillaldehyde into a coating machine for coating to obtain coated peanuts, which are stored at room temperature. Preserve the peanuts coated with the method of the present invention and the peanuts not treated with the coating at room temperature (30° C.) for 100 days, the results are shown in figure 2 ,3. From figure 2 and image 3 It can be seen that the number of Aspergillus flavus in the peanuts coated with perillaldehyde-sodium alginate composite film was 10 after being stored at 30°C for 100 days. 3 cfu / g peanut ( figure 2 ), the number...

Embodiment 2

[0024] Add 35ul of food additive perillaldehyde to 100g of peanut kernels, mix well in a closed container, put it into an ultrasonic processor for ultrasonic treatment, the ultrasonic frequency is 70kHz, the ultrasonic power is 110W, the ultrasonic temperature is 40°C, and the ultrasonic time is 40min . Add 100 g of peanut kernels and 60 ml of 0.1% sodium alginate coating liquid that have been ultrasonically treated with perillaldehyde into a coating machine for coating to obtain coated peanuts, which are stored at room temperature. The peanuts coated with the method of the present invention and the peanuts not treated with coatings were stored at room temperature (30°C) for 100 days, and the results are shown in Figure 4 .

[0025] Add 35ul of food additive perillaldehyde to 100g of peanut kernels, mix them evenly in an airtight container, and let them stand for 40min. Add the treated 100g of peanut kernels and 60ml of 0.1% sodium alginate coating solution into the coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com