Green tea processing process

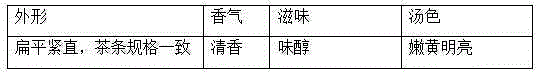

A processing technology and green tea technology, applied in the field of tea processing, can solve the problems affecting processing quality, mixed tea leaves, astringent taste of green tea, etc., and achieve the effect of ensuring quality, green color and uniform specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The processing technology of present embodiment green tea comprises the following steps:

[0028] The first step: select leaves, choose medium and small tea tree varieties, and choose fresh leaves with one bud and one leaf for exhibition, and the buds are longer than the leaves;

[0029] The second step: the tea leaves selected in the first step are fixed, using a drum continuous greening machine, the amount of leaves is 0.15Kg each time, and the leaves are evenly dumped when the leaves are thrown, the drum speed is 20rpm / min, and the temperature is controlled at 130 o until the moisture content of the tea leaves is 58%;

[0030] The third step: put the tea leaves obtained in the second step on the sieve to redistribute the water, and control the cooling temperature at 18 o C, the relative humidity is controlled at 50%, the wind speed is 0.4m / s, and the cooling time is controlled at 6 hours;

[0031] The fourth step: sieve the tea leaves obtained in the third step to ...

Embodiment 2

[0037] The processing technology of present embodiment green tea comprises the following steps:

[0038] The first step: select leaves, choose medium and small tea tree varieties, and choose fresh leaves with one bud and one leaf for exhibition, and the buds are longer than the leaves;

[0039] The second step: the tea leaves selected in the first step are fixed, using a drum continuous greening machine, the amount of leaves thrown is 0.18Kg each time, and the leaves are evenly dumped when the leaves are thrown, the rotating speed of the drum is 25rpm / min, and the temperature is controlled at 135 o until the moisture content of the tea leaves is 65%;

[0040] The third step: put the tea leaves obtained in the second step on the sieve to redistribute the water, and control the cooling temperature at 19 oC , the relative humidity is controlled at 50%, the wind speed is 1.2m / s, and the cooling time is controlled at 8 hours;

[0041] The fourth step: sieve the tea leaves obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com