Optical mask

An optical surface, optical technology, applied in the direction of phototherapy, can solve the problems of difficult process, troublesome product maintenance, serious hygiene problems, etc., and achieve the effect of convenient use, ingenious structure design and powerful function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

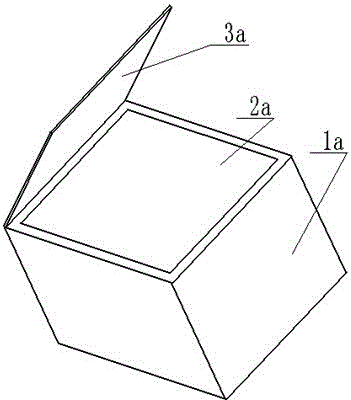

[0030] Such as figure 1 As shown, an optical mask includes an optical host and a maintenance film. The maintenance film is a mask, and the maintenance film is composed of a light-absorbing layer, a base layer and a surface layer. The light-absorbing layer, the base layer, and the surface layer are arranged in sequence. The light-absorbing layer is made by mixing rare metal particles and light-absorbing crystal materials, and the rare metal particles are nanoparticles. When absorbing light, put the maintenance film into the optical host. The optical host includes pulse light source, controller, host body and function keys. The pulse light source includes blue light waves of 410-430nm, red light waves of 640-660nm, and purple light waves of 380-420nm. , 600-630nm orange light wave and 890-920nm far-infrared light wave combined light source, the pulse light source and controller are set inside the optical host, the function keys are set outside the optical host, the controller is...

Embodiment 2

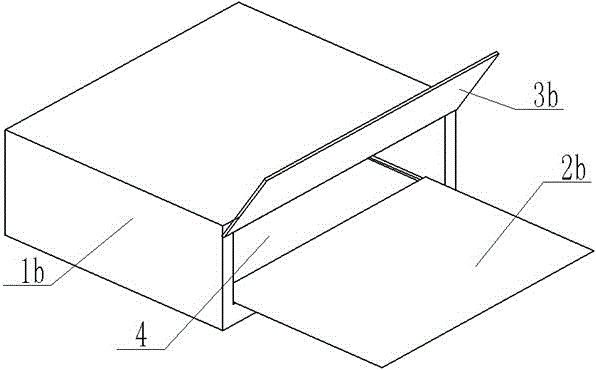

[0032] Such as figure 2 As shown, an optical mask includes an optical host and a maintenance film. The maintenance film is a mask, and the maintenance film is composed of a light-absorbing layer. The light-absorbing layer includes rare metal particles and light-absorbing crystal materials. , there are rare metal particles as nanoparticles, and the maintenance film is placed in the optical host when absorbing light. The optical host includes a pulse light source, controller, main body and function keys. The pulse light source includes blue light waves of 410-430nm, red light waves of 640-660nm, purple light waves of 380-420nm, orange light waves of 600-630nm and 890-920nm light waves. The combined light source of the far-infrared light wave, the pulse light source and the controller are set inside the optical host, the function keys are set outside the optical host, the controller is connected with the pulse light source and the function keys, the main body is set as a pull-ou...

Embodiment 3

[0034] Such as figure 1 As shown, an optical mask includes an optical host and a maintenance film. The maintenance film is a body film, and the maintenance film is a light-absorbing layer. The light-absorbing layer includes rare metal particles and light-absorbing crystal materials, and the light-absorbing layer is formed by mixing rare metal particles and light-absorbing crystal materials. , with rare metal particles as nanoparticles. When absorbing light, put the maintenance film into the optical host. The optical host includes pulse light source, controller, host body and function keys. The pulse light source includes blue light waves of 410-430nm, red light waves of 640-660nm, and purple light waves of 380-420nm. , 600-630nm orange light wave and 890-920nm far-infrared light wave combined light source, the pulse light source and controller are set inside the optical host, the function keys are set outside the optical host, the controller is connected with the pulse light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com