Composite damping baseball bat and production process thereof

A production process and technology for baseball bats, applied to rackets, sports accessories, etc., can solve the problems of fragile structure, complex production methods, laborious and other problems, and achieve the effect of not easy to break or concave damage, high overall structural strength, and comfortable hitting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

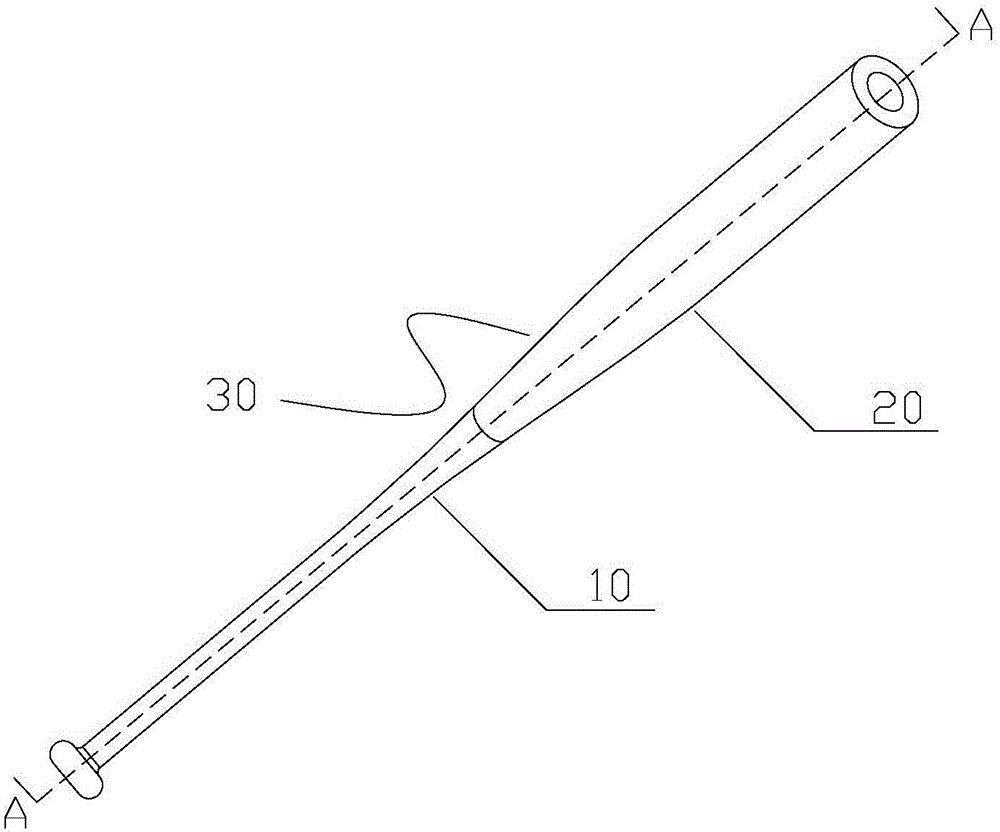

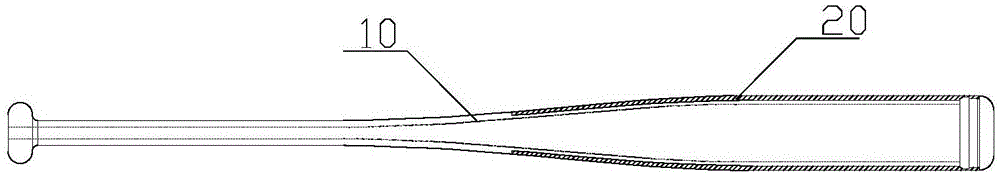

[0031] refer to Figure 1 to Figure 5 , propose an embodiment of a composite shock-absorbing baseball bat of the present invention:

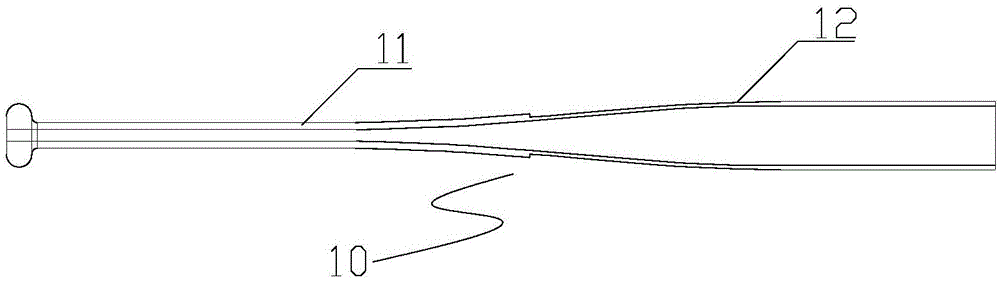

[0032] A composite shock-absorbing baseball bat includes a baseball bat body 30 composed of a mandrel 10 and a striking sleeve 20 , and an epoxy resin layer 40 formed by potting epoxy resin on the outer wall of the baseball bat body 30 . The core rod 10 is a soft rod formed by weaving carbon fiber (or glass fiber or aramid fiber), which has a shock-absorbing effect. The mandrel 10 includes a grip portion 11 and a shock absorbing portion 12 .

[0033] The hitting sleeve 20 is a hollow hitting sleeve 20 rolled from an aluminum alloy pipe. The hitting sleeve 20 is set on the ball hitting shock absorbing portion 12 to cover the ball hitting shock absorbing portion 12. The hitting sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com