Tilting-type automatic coating machine and working method

An automatic coating and tilting technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of liquid and liquid splashing, confinement, and coating liquid splashing outward, so as to improve the drying efficiency and improve the efficiency. , the effect of simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

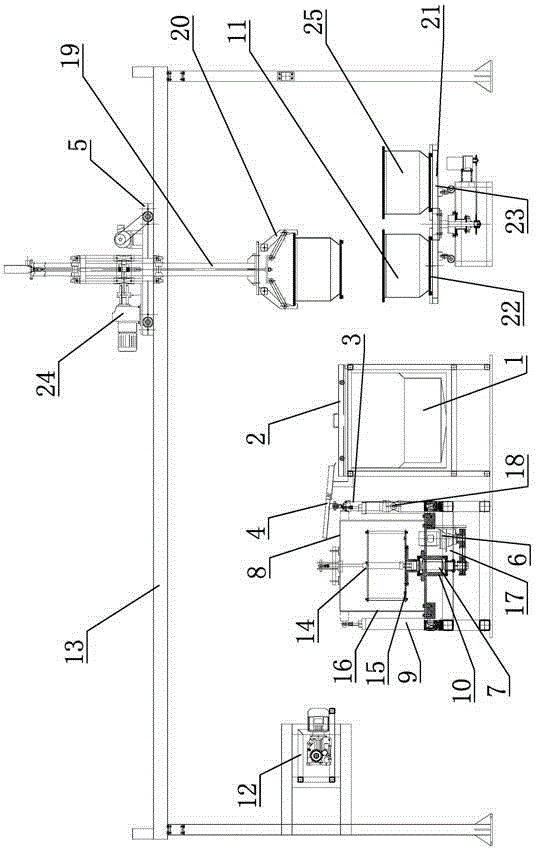

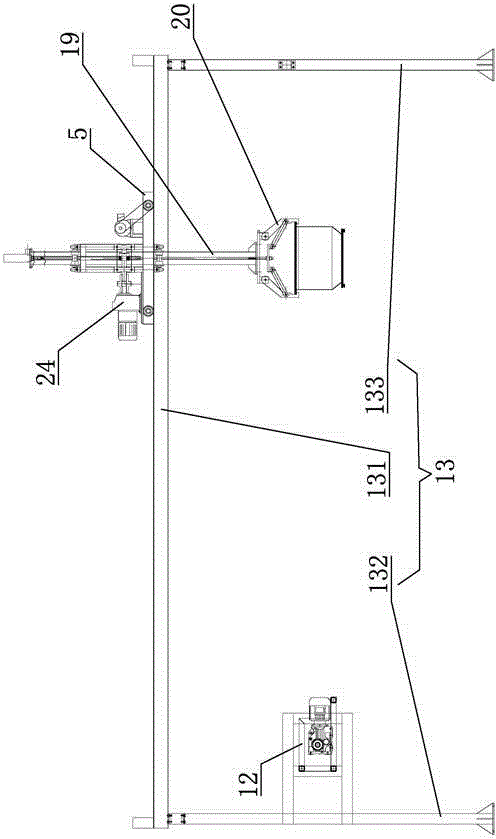

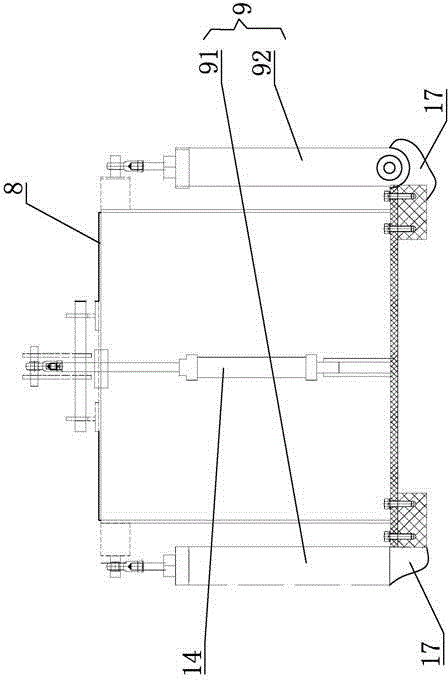

[0037] Such as Figure 1-7 As shown, the inclined automatic coating machine of the present invention includes: liquid coating tank 1, liquid coating tank cover 2, cylinder 3, transition plate 4, trolley 5, reduction motor 6, transmission shaft 7, cylinder cover 8, swing hydraulic cylinder 9. Shaft sleeve 10, basket one 11, turnover mechanism 12, walking frame 13, hydraulic cylinder 14, spin bracket 15, spin slot 16, base 17, hinge 18, lift cylinder 19, manipulator 20, rotating tray 21. Grabbing station 22, waiting station 23, lifting motor 24, basket two 25.

[0038] The coating liquid tank 1 for holding the coating liquid has an opening facing upward and a coating liquid tank cover 2 is provided on the top. The coating liquid tank 1 is provided with a transition plate 4 on the upper left side. The transition plate 4 is composed of a transition plate 41 that is hinged to each other. The bottom of the second transition plate 42 is fixedly connected to the left edge of the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com