Method for preparing laser cladding layer through double-layer organic coating iron-based alloy powder

An iron-based alloy and laser cladding technology, applied in coatings, metal material coating processes, etc., can solve the problems of reduced mechanical properties, high boron and silicon content, easy cracking of the cladding layer, etc. The effect of comprehensive high quality and less defects such as slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

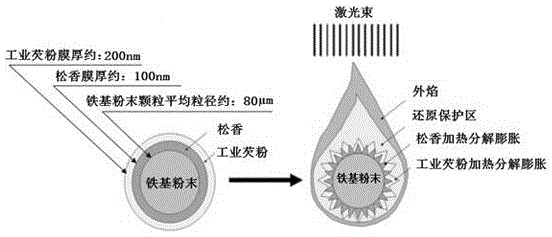

[0033] For the preparation of iron-based alloy powder, according to the mass percentage, 15%-19% of chromium, 2%-9% of nickel, 0.05%-0.15% of boron content, 0.1%-0.7% of silicon content, and no more than 0.3% of carbon content are selected. The balance is iron; it is 0.06%-0.2% rosin (molecular formula C 19 h 29 COOH), and alloy powder weight percentage is 0.15%-0.4% industrial gorgon powder (molecular formula (C 6 h 10 o 5 )n).

[0034] Then add the selected rosin in absolute ethanol, the ratio is to add 0.85-2.85g of rosin per 100mL of absolute ethanol; then stir to dissolve; the above-mentioned iron-based alloy powder containing Cr, Ni, B, Si, C and other elements , according to the ratio of adding 100g of iron-based alloy powder to every 7mL of absolute ethanol, adding the weighed above-mentioned iron-based alloy powder into absolute ethanol in which rosin has been dissolved, and stirring to obtain a mixed slurry;

[0035] Put the prepared mixed slurry on the electric...

Embodiment 1

[0057] According to the mass percentage, choose 15% Cr, 2% Ni, 0.05% B, 0.1% Si, 0.1% C, and the iron-based alloy powder whose balance is Fe; The rosin and the iron-based alloy powder are 0.15% by weight of industrial gorgon powder. Then add the selected rosin in dehydrated alcohol, the ratio is to add 0.85g rosin in every 100mL dehydrated alcohol; then stir and dissolve; the above-mentioned iron-based alloy powder containing elements such as Cr, Ni, B, Si, C, according to The proportion of adding 100g of iron-based alloy powder per 7mL of absolute ethanol, the above-mentioned iron-based alloy powder containing elements such as Cr, Ni, B, Si, C, etc., is added to the absolute ethanol in which rosin has been dissolved, and stirred to obtain a mixed Slurry: put the prepared mixed slurry on the electric furnace while heating and stirring, evaporate the absolute ethanol to dryness, put the evaporated material in a blast drying oven at a drying temperature of 40°C, further dry it, ...

Embodiment 2

[0059] According to the mass percentage, choose 17% Cr, 5.0% Ni, 0.10% B, 0.5% Si, 0.3% C, and the iron-based alloy powder whose balance is Fe; the weight percentage with the iron-based alloy powder is 0.1% The rosin and the iron-based alloy powder are 0.3% by weight of industrial gorgon powder. Then add the selected rosin in absolute ethanol, the ratio is to add 2.85g of rosin per 100mL of absolute ethanol; then stir to dissolve; The ratio of adding 100g of iron-based alloy powder to absolute ethanol is to add the above-mentioned iron-based alloy powder containing Cr, Ni, B, Si, C and other elements into the absolute ethanol in which rosin has been dissolved, and stir to obtain a mixed slurry ; Place the prepared mixed slurry on the electric furnace while heating and stirring, evaporate the absolute ethanol to dryness, put the evaporated material in a blast drying oven at a drying temperature of 80°C, further dry it, and take it out after 12 hours; The mixed powder material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com