Rubber pad independent of base mold and preparing method of rubber pad

A technology of rubber pad and mold body, applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of complex production process, loss of isostatic pressure effect, loss of mold body pressure, etc., and achieve more sensitive and more sensitive pressure equalization effect. Improve product defects and ensure the effect of pressure equalization function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

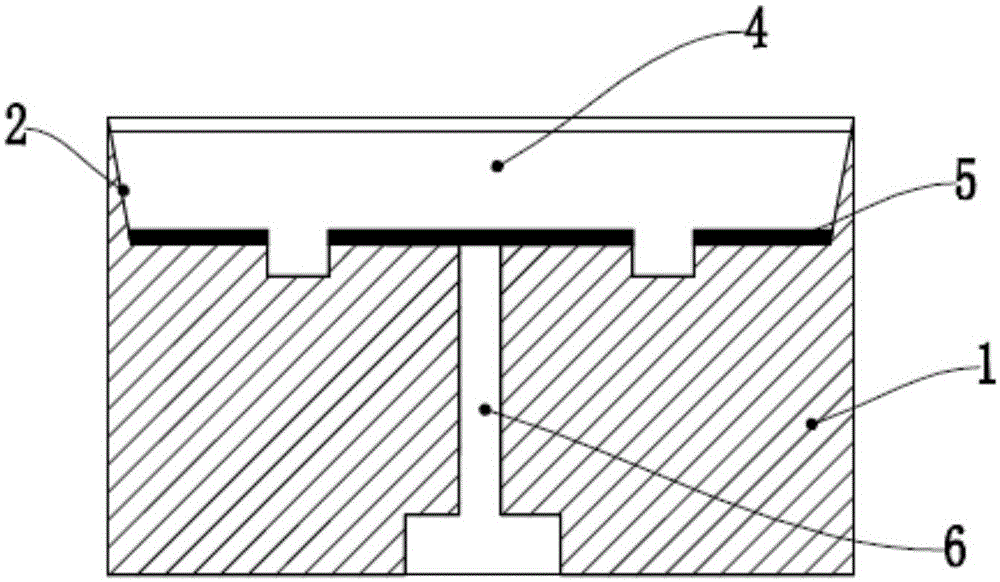

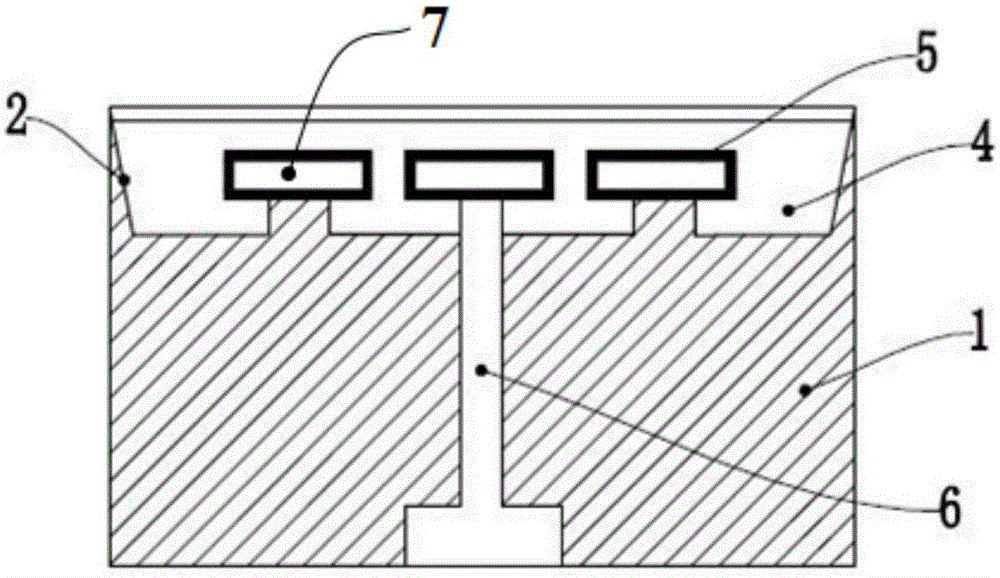

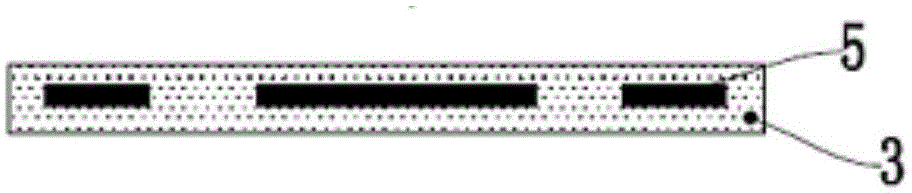

[0046] Such as Figure 4 Shown, use above-mentioned a kind of isostatic pressure ceramic tile mold that is independent of the rubber pad outside the matrix mold body, comprise base body 1, glue-holding cavity 2, elastic geometric cushion body 3 and filling colloid 4, described glue-holding cavity Cavity 2 is opened on the stamping surface of the base body 1, the glue-holding cavity 2 is filled with the filling colloid 4, and the elastic geometric cushion body 3 is fixed and poured in the glue-holding space of the isostatic tile mold by the filling colloid 4 chamber 2.

[0047] In the present invention, the elastic geometric cushion body 3 filled with a liquid substance is placed in the surface-cast concave surface of the base body 1, the elastomer liquid glue is poured into the poured concave surface and molded and solidified to form the filling colloid 4, and the elastic geometric cushion body 3 is fixed In the plastic cavity 2. The obtained mold for isostatic pressing cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com