Slide way type side-loading classified-compression refuse truck

A garbage truck and slide-type technology, applied in the field of sanitation vehicles, can solve the problems of waste of resources, complicated installation, and small space for the arrangement of hydraulic components, and achieve the effects of strong practicability, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment;

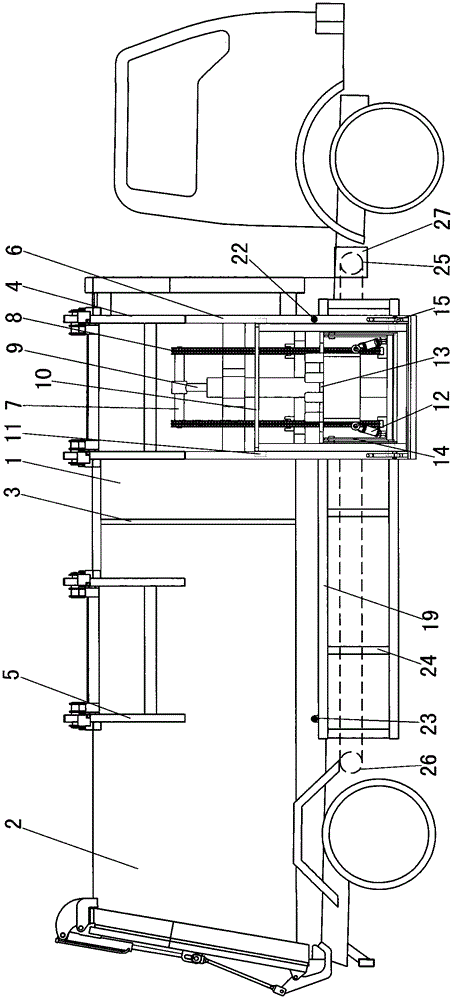

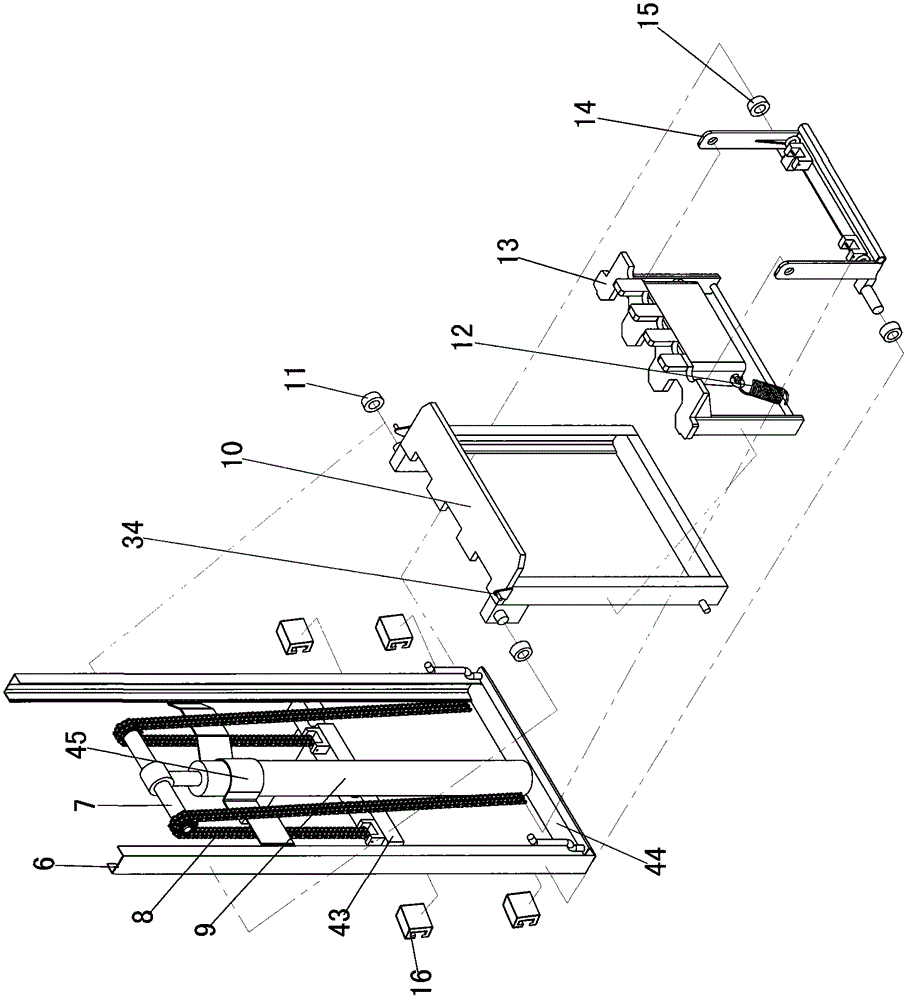

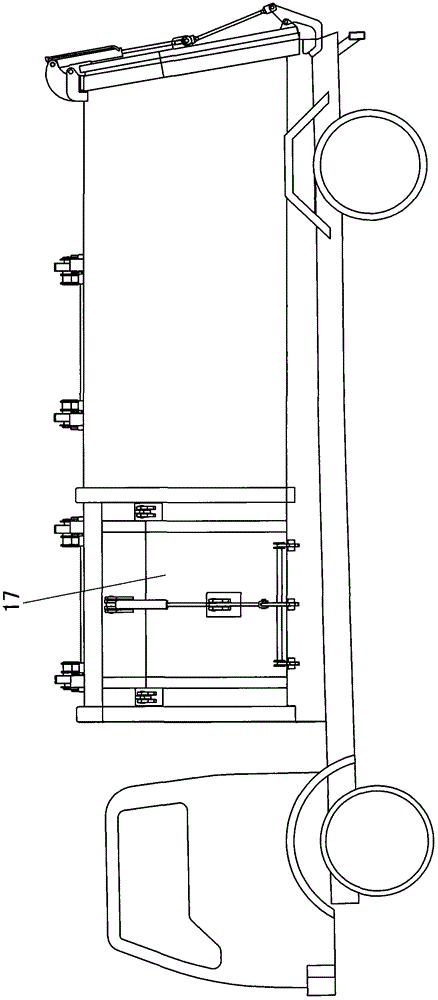

[0032] Such as Figure 1 to Figure 7 As shown, the compartment of the slideway type side-mounted sorting compression garbage truck of the present invention is divided into a front compartment 1 and a rear compartment 2 by a partition 3 . The top of the front bin 1 is provided with a front bin feeding port, and the top of the rear bin 2 is provided with a rear bin feeding port. On the front warehouse 1, the first upper sliding track 4 and the front warehouse opening door 17 are arranged, and the second upper sliding track 5 and the rear warehouse opening door 18 are arranged on the rear warehouse 2. On the front warehouse 1 and the rear warehouse 2, there are also A push rod 30, a spring 31 and a material opening door 32 are arranged respectively. The upper ends of the first upper sliding track 4 and the second upper sliding track 5 extend to the feed port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com