A ball mill grinding ball and a method for improving the performance of construction waste recycled concrete aggregate

A technology of recycled concrete and construction waste, applied in the direction of climate sustainability, sustainable waste treatment, grain treatment, etc., can solve the problem of affecting the physical properties and usability of recycled aggregates, affecting the physical properties and usability of recycled coarse aggregates Surface roughness and other problems, to reduce the surface and internal crack damage of the aggregate, enhance the mechanical stability and anti-wear performance, and achieve the effect of full and round aggregate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Ball mill grinding ball:

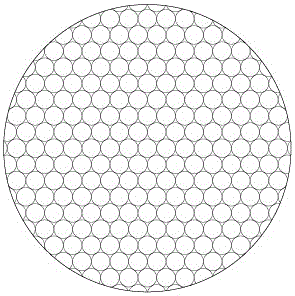

[0031] The schematic diagram of the structure of the ball mill used in this embodiment is as follows: figure 1 As shown, the ball surface of the ball mill is provided with spherical crown-shaped pits along the circumferential direction, the pits in the same row and the pits in the two adjacent rows are tangent, and the pits in the two adjacent rows are in the same position. Wrong; the diameters of the grinding balls of the ball mill are respectively 30mm, 40mm and 50mm, the diameters of the spherical crowns of the pits are respectively 4.0mm, 5.3mm and 6.5mm, and the corresponding depths are respectively 0.13mm, 0.18mm and 0.21mm, The total surface area of the pits is 80%-90% of the surface area of the ball.

[0032] Two, a method for improving the performance of construction waste recycled concrete aggregate:

[0033] In this embodiment, when processing the concrete block of construction waste, the concrete block is firstly treated w...

Embodiment 2

[0049] 1. Ball mill grinding ball:

[0050] The grinding ball surface of the ball mill used in this embodiment is provided with spherical crown-shaped pits along the circumferential direction, and the pits in the same row and between the two adjacent rows of pits are equally spaced, and the positions of the two adjacent rows of pits The diameters of the grinding balls of the ball mill are 30mm, 40mm and 50mm respectively, the diameters of the spherical caps of the pits are respectively 5.0mm, 6.6mm and 8.3mm, and the corresponding depths are 0.21mm, 0.27mm and 0.34mm respectively , the total surface area of the pits is 83%-93% of the surface area of the ball.

[0051] Two, a method for improving the performance of construction waste recycled concrete aggregate:

[0052] In this embodiment, when processing the concrete block of construction waste, the concrete block is firstly treated with jaw crusher, and the discharge diameter of the jaw crusher is adjusted to 20-25mm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com