Three-phase separator

A technology of three-phase separator and cyclone separator, which is applied in the direction of production fluid, wellbore/well components, and only multi-stage series refining process, etc., which can solve the problem of short circuit of electrode plate, gas-liquid separation and oil-water separation The effect is not good enough, the oil-water separation efficiency is not high, etc., to achieve good gas separation effect, improve oil-water separation effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

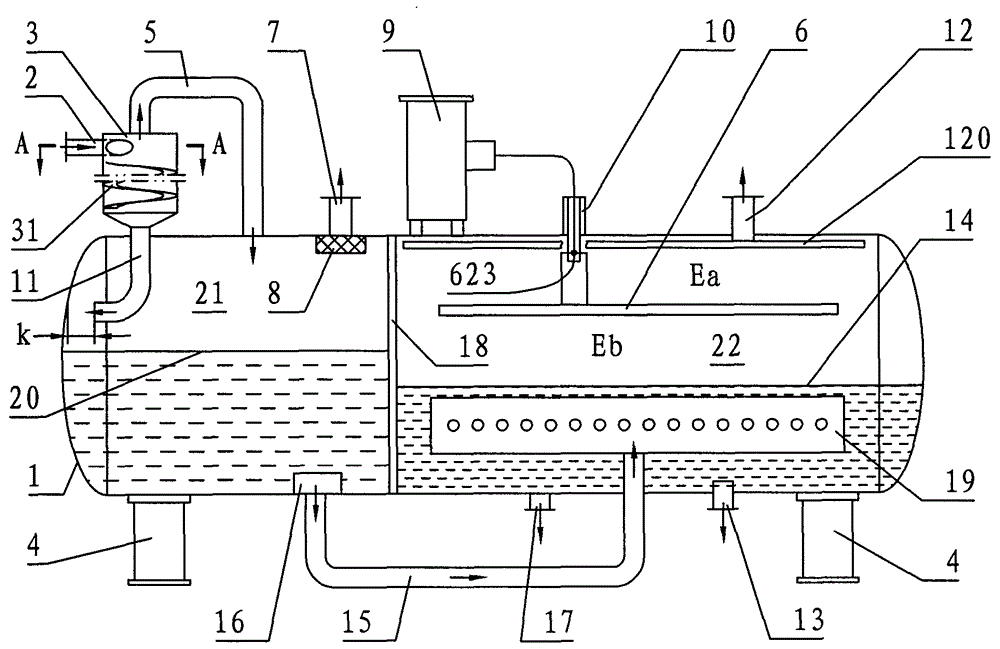

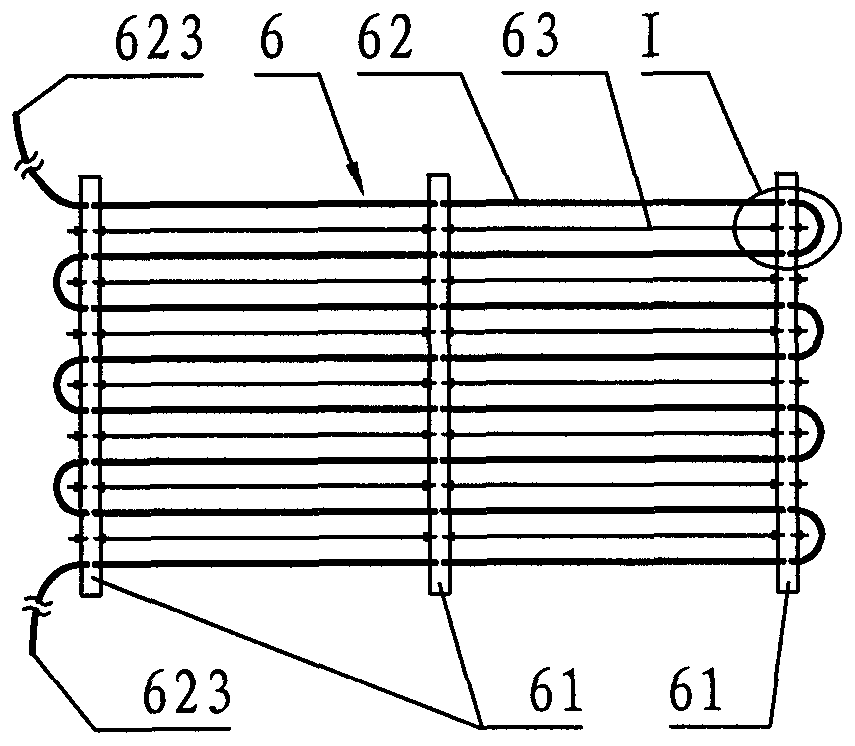

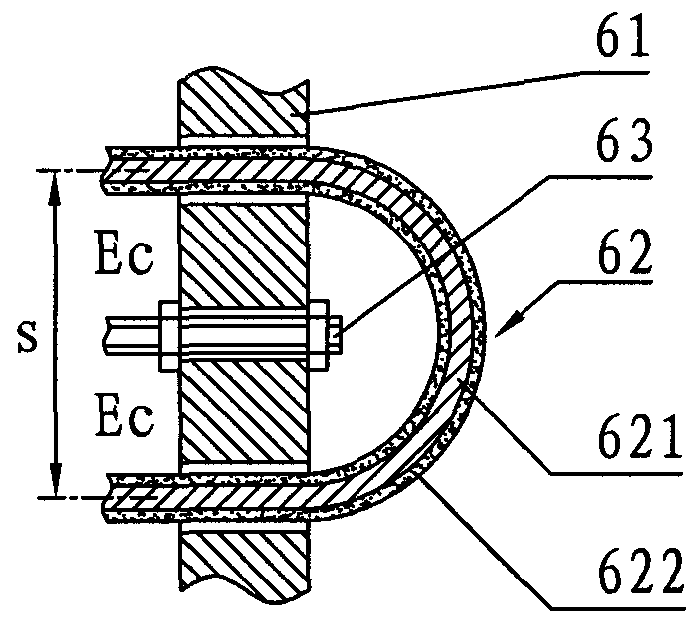

[0014] see figure 1 , A three-phase separator of the present invention is provided with a tank body 1, a cyclone separator 3, an exhaust pipe 7, a transformer 9, and a high-voltage electricity introduction pipe 10. The tank body 1 is a horizontal tank supported by a support 4 . The inner cavity of the tank body 1 is provided with a partition 18 , and the partition plate 18 divides the inner cavity of the tank body 1 into a gas-liquid separation chamber 21 and an oil-water separation chamber 22 . The shell of the cyclone separator 3 is composed of an upper cylindrical shell and a lower inverted truncated conical shell, and a feed pipe 2 is provided along the tangential direction of the cylindrical shell of the cyclone separator 3 . A liquid outlet pipe 11 is provided at the bottom of the cyclone separator 3 , and the outlet of the liquid outlet pipe 11 is located in the gas-liquid separation chamber 21 . An oil outlet pipe 12 is provided at the position of the oil-water separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com