Method for preparing novel classification TiO2 nanotube array

A nanotube array, a new type of technology, applied in the field of preparation of new graded TiO2 nanotube arrays, can solve the problems of ZnO inexhaustible etching and affecting the performance of TiO nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

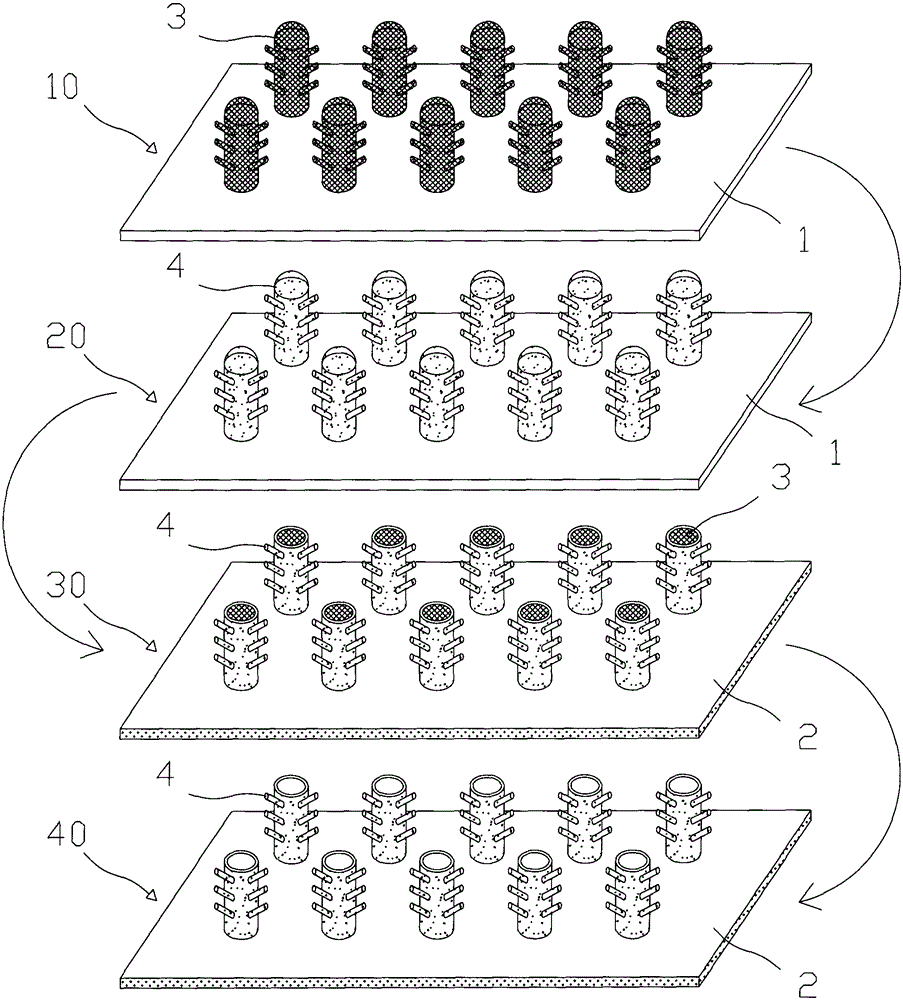

[0021] For further describing the novel graded TiO of the present invention 2 The preparation method of the nanotube array will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 As shown, a novel hierarchical TiO 2 The preparation method of nanotube array, the steps are as follows:

[0023] ①. Preparation of ZnO hierarchical structure template by electrolytic deposition method 10

[0024] Dissolve 0.0063M zinc nitrate and 0.0063M hexamine (Hexamine) into 200mL deionized water as the electrolyte, connect the ITO substrate to the gold wire of the working electrode, and conduct electrolytic deposition with the same gold wire as the reference electrode (process parameters The deposition voltage is -2.5V, the deposition time is 60 minutes, and the temperature of the electrolyte is 95°C), and then the prepared sample is annealed at 350°C for 30 minutes in an air environment to obtain ZnO nanorods.

[0025] Dissolve 0.0063M zinc nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com