Flocculating and water-saving washing machine and control method

A technology of a water-saving washing machine and a control method, applied in the field of washing machines, can solve the problems of high use cost, inability to recycle laundry water, and inability to use, and achieve the effects of reducing pollution, eliminating manual cleaning, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

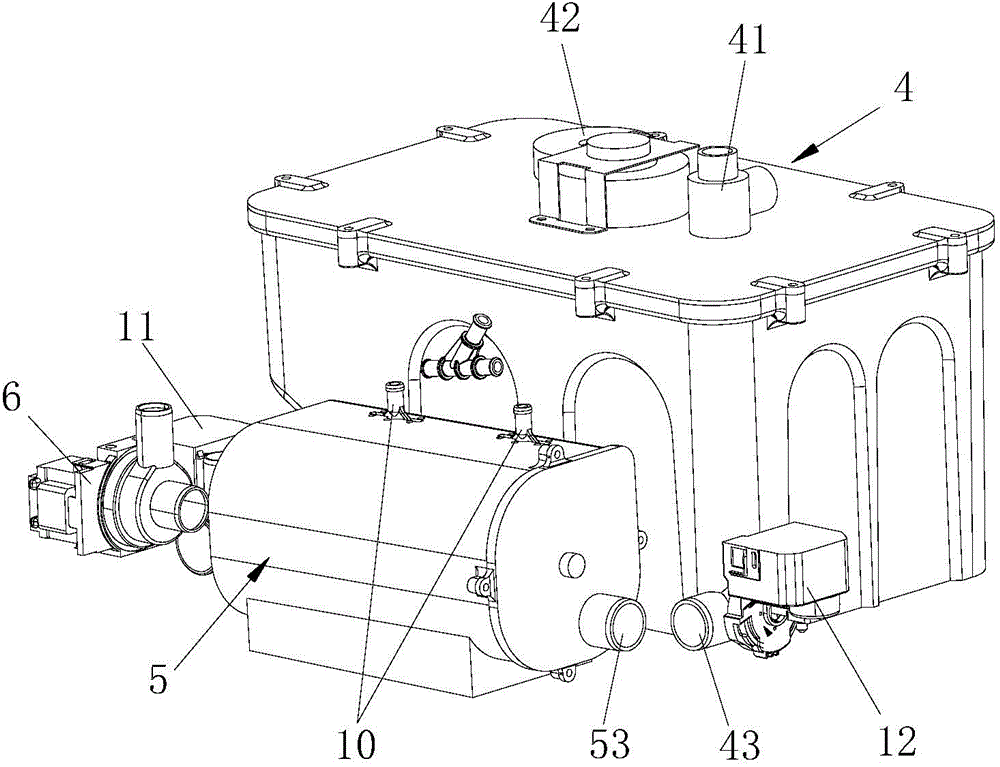

[0049] Such as Image 6 As shown, the cleaning mechanism 8 described in this embodiment includes a water throwing impeller 81 that throws the incoming water toward the inner wall of the flocculation container 4 and a driving motor 82 that drives the water throwing impeller 81 to rotate; A stirring motor 71 outside the container 4 , a stirring shaft 72 extending to the inside of the flocculation container 4 and a stirring impeller 73 installed on the stirring shaft 72 .

[0050] The driving motor 82 described in this embodiment is arranged above the flocculation container 4 , the stirring motor 71 is arranged at the bottom of the flocculation container 4 , and the stirring shaft 72 extends upward to the interior of the flocculation container 4 . In addition to this structure, the stirring motor can also be arranged on the side of the flocculation container, and the stirring shaft extends from the side to the inside of the flocculation container, or both the stirring motor and t...

Embodiment 2

[0052] Such as Figure 7 with Figure 8 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. The drive motor 82 and the stirring motor 71 are the same motor, and the water throwing impeller 81 is coaxially installed on the stirring shaft 72, the bending direction of the stirring impeller 73 is opposite to the rotation direction of the stirring shaft during the stirring process. The structure of the stirring impeller can not only stir the water flow to accelerate the dissolution of the flocculant, but also prevent the water flow from breaking up the flocs due to excessive water flow. A water guiding groove 44 is arranged in the flocculation container 4 to guide the water from the water inlet 41 of the flocculation container to the impeller 81 for throwing water. The gutter structure is not essential, as Image 6 As shown, the water inlet 41 is above the water-spinning impeller 81, and the water enters until the water-spinning impeller.

[005...

Embodiment 3

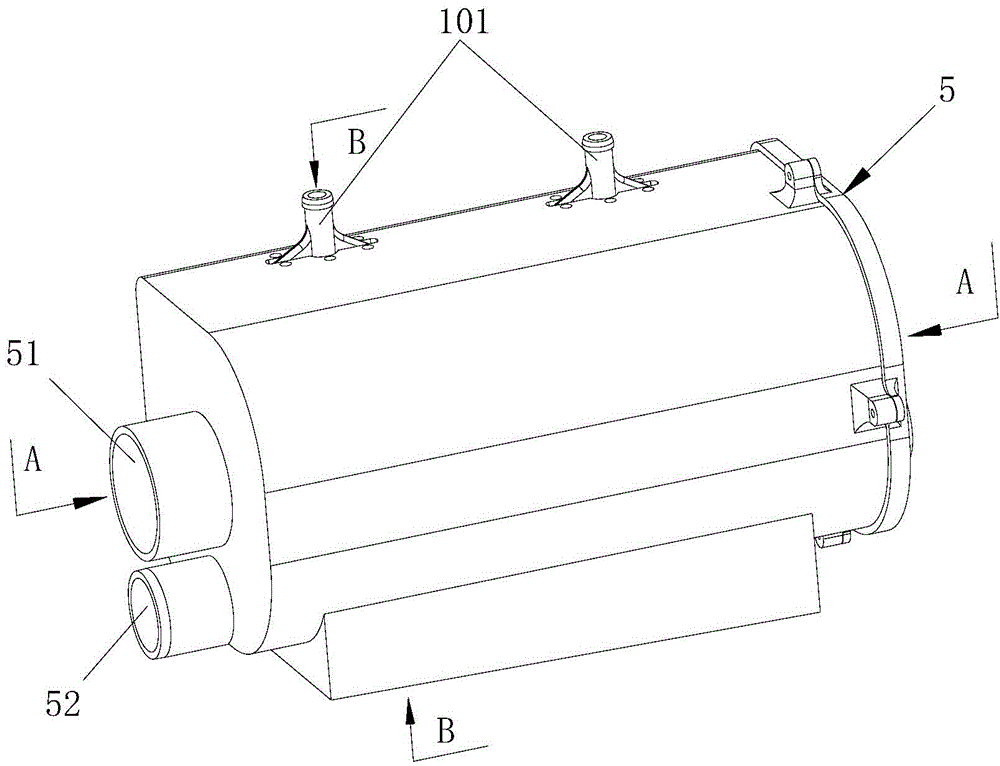

[0055] Such as Figure 4 with Figure 5 As shown, the filter mechanism 9 described in this embodiment includes a filter bucket 91 and a filter screen 92 located on the filter bucket. The water outlet joint 93 is rotated, and the other end is sealed; the rotation axial direction L of the filter mechanism 9 and the horizontal plane R have an inclined angle α, 0≤α≤30°. By tilting or placing the filtering mechanism horizontally, not only the filtering area can be increased, the filtering speed can be accelerated, but also the cleaning of the filtering net can be facilitated.

[0056] The filtered water flow path of this embodiment is that the treated water after flocculation in the flocculation container 4 enters the filter container 5 through the filter water inlet 53, enters the filter barrel 91 after being filtered by the filter screen 92, and then is filtered by the rotary water outlet joint 93 at the end. The water outlet 51 is discharged into the tub 2 of the washing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com