Intelligent road construction device with good heat radiation

A road construction device and a technology for road construction, applied in the field of intelligent road construction devices, can solve the problems that the amount of material removal is not large, the cost of grinding machinery and equipment is not suitable, and achieves increased flexibility, increased diameter, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

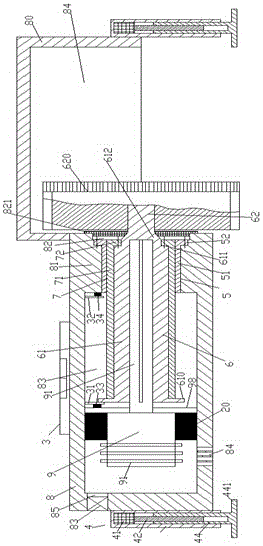

[0008] Combine below figure 1 The present invention will be described in detail.

[0009] An intelligent road construction device with good heat dissipation according to an embodiment, used for grinding local protrusions on the construction road surface during road construction, including an external casing 8, a motor 9 and a grinding head driven by the motor 9 The drive rod part 6, wherein the motor 9 is axially and slidably power-coupled with the spline hole in the drive sleeve part 61 of the grinding head drive rod part 6 through the fixedly coupled spline rod 91, so The driving sleeve part 61 of the grinding head driving rod part 6 is fixedly connected with the grinding head installation rod part 62 of the grinding head driving rod part 6 through the tapered connection part 612, and the grinding head installation rod part 62 is detachably installed There is a grinding head 620, and the outer peripheral surface of the driving sleeve part 61 is provided with an axially exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com