All-glass curtain wall support structure and installation method of all-glass curtain wall

A technology of supporting structure and installation method, which is applied in the direction of walls, building components, building structures, etc., can solve problems such as broken glass ribs, and achieve the effects of preventing breakage, ensuring safety, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

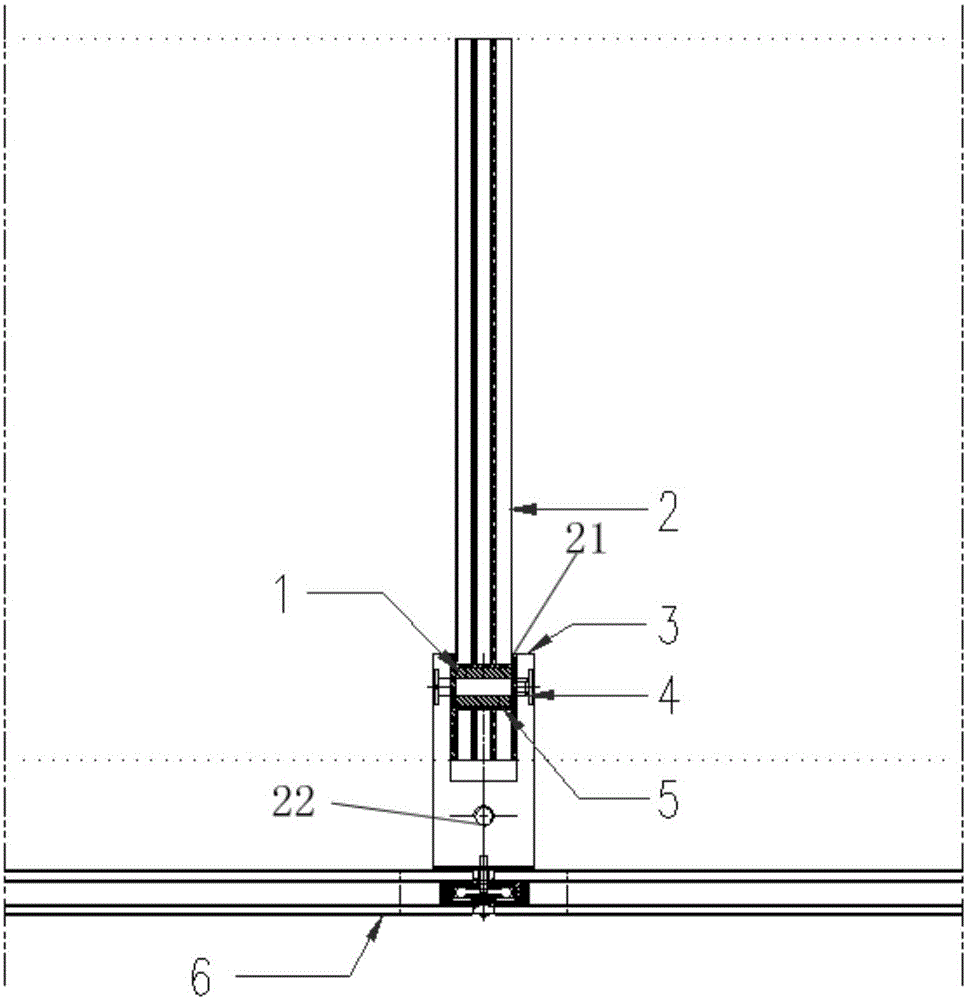

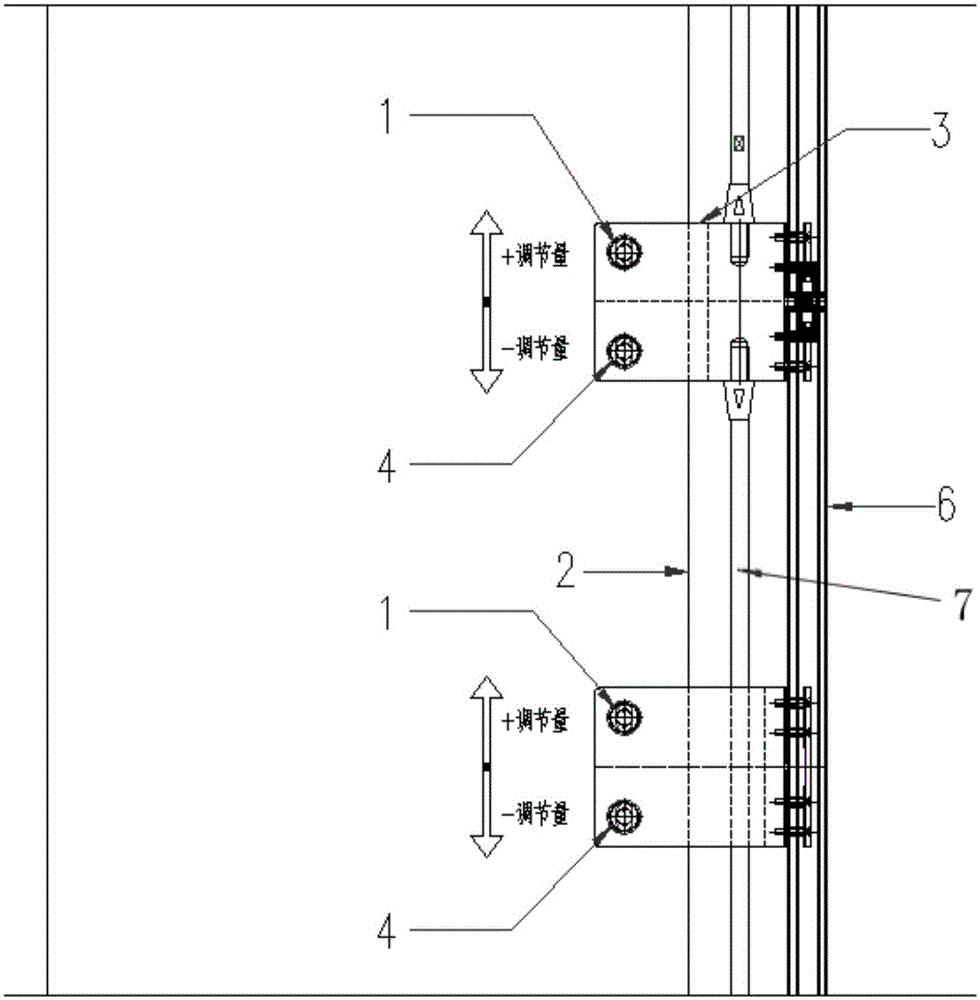

[0032] This embodiment provides an all-glass curtain wall support structure, such as Figure 1-3 as shown,

[0033] It includes a tie rod 7 arranged in the vertical direction, a connecting piece 3 is arranged on the tie rod 7, one end of the connecting piece 3 is connected with the glass panel 6, and the other end of the connecting piece 3 is connected to the glass rib through the fixing piece 4 2 fixed.

[0034] Such as figure 1 As shown, the connecting member 3 is also provided with a connecting hole 22 through which the pull rod 7 passes or is fixed, and the pull rod 7 is connected to the connecting member 3 through the connecting hole 22 .

[0035] Such as figure 1 As shown, the connector 3 is also formed with a receiving groove 21 along the vertical direction for accommodating part of the glass rib 2, and the part of the glass rib 2 located in the receiving groove 21 has a through hole, and the groove of the receiving groove 21 A mounting hole is provided on the wall,...

Embodiment 2

[0047] This embodiment provides an all-glass curtain wall installation method having the all-glass curtain wall support structure described in Embodiment 1, comprising the following steps:

[0048] Position and install the glass rib 2 and the pull rod 7 along the vertical direction;

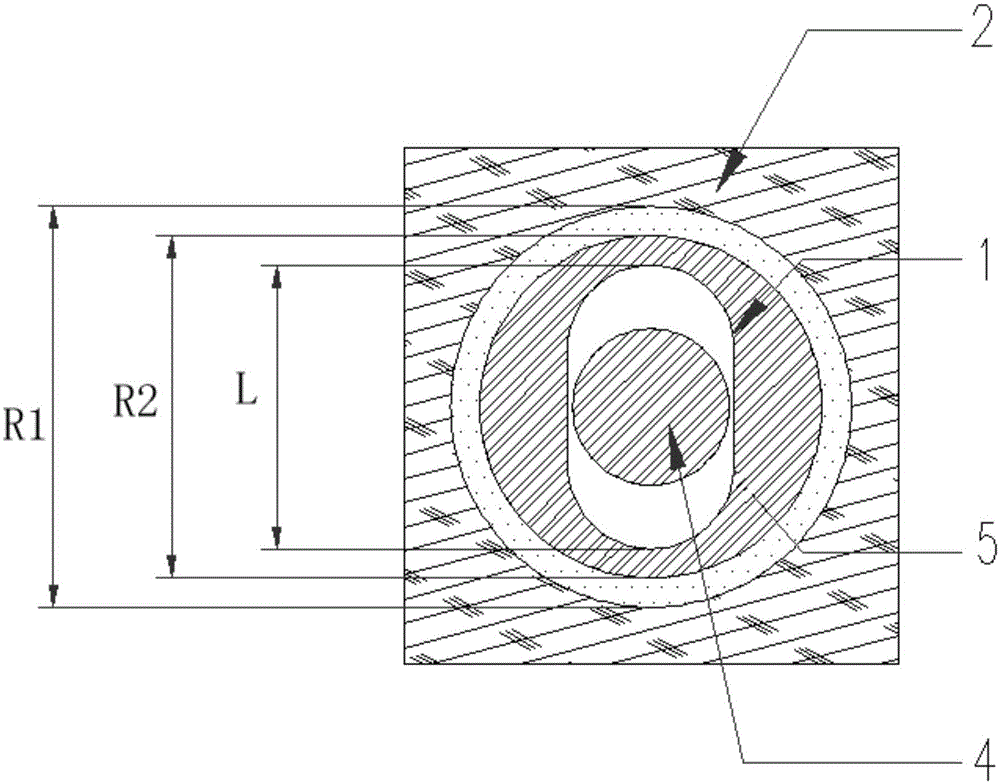

[0049] Put the gasket 1 into the through hole of the glass rib 2, and use glass glue to fill the gap between the gasket 1 and the through hole of the glass rib 2 with glass glue;

[0050] The connecting piece 3 is arranged on the pull rod 7, and the fixing piece 4 is passed through the installation hole, the long waist hole or the strip hole in the washer 1 and the installation hole on the other side of the connecting piece 3 from one side of the connecting piece 3. The connecting piece 3 is fixed to the glass rib 2, and the fixing piece 4 is arranged in the middle of the long waist hole or the strip-shaped hole, and there is a certain gap between the top and bottom inner walls of the long waist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com