Efficient drill cement tool

A high-efficiency and tool-based technology, applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as slow footage, easy to leave residual ash, and irregular well diameter in drilling ash sections, and achieve simple connection structure, reliable and stable connection , Simple and reliable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

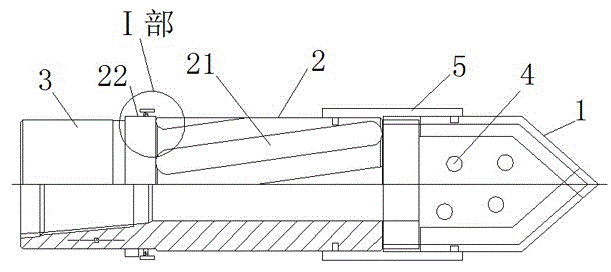

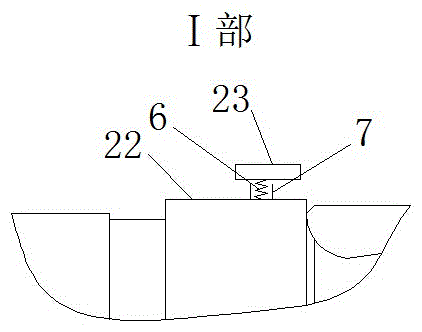

[0016] The present invention comprises a point drill bit 1, a pear-shaped milling cone 2 and a joint 3, the pointed drill bit 1 is arranged at the bottom of the pear-shaped milling cone 2, and the pear-shaped milling cone 2 is arranged at the bottom of the joint 3; the pear-shaped milling cone 2. Some water outlet grooves 21 are evenly distributed around, and a circular protrusion 22 is arranged at the rear of the water outlet groove 21 in the circumferential direction of the pear-shaped milling cone 2, and a hard alloy 23 is arranged on the circular protrusion 22.

[0017] The tool has a cylindrical structure as a whole, and a water eye 4 in the form of a folded structure is arranged inside the cylinder, and the water eye 4 communicates with the water outlet groove 21 .

[0018] The lower part of the pear-shaped milling cone 2 is a plane structure, and a cuboid groove is opened in the plane, and the pointed drill bit 1 is arranged in the cuboid groove.

[0019] A sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com