Device and method for generating power by virtue of waste heat of internal combustion engine

A waste heat power generation and internal combustion engine technology, applied in the direction of internal combustion piston engines, noise reduction devices, exhaust devices, etc., can solve the problems of low thermoelectric conversion efficiency and limited heat from exhaust gas, so as to increase the installation area and quantity, fully collect and utilize, The effect of raising the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

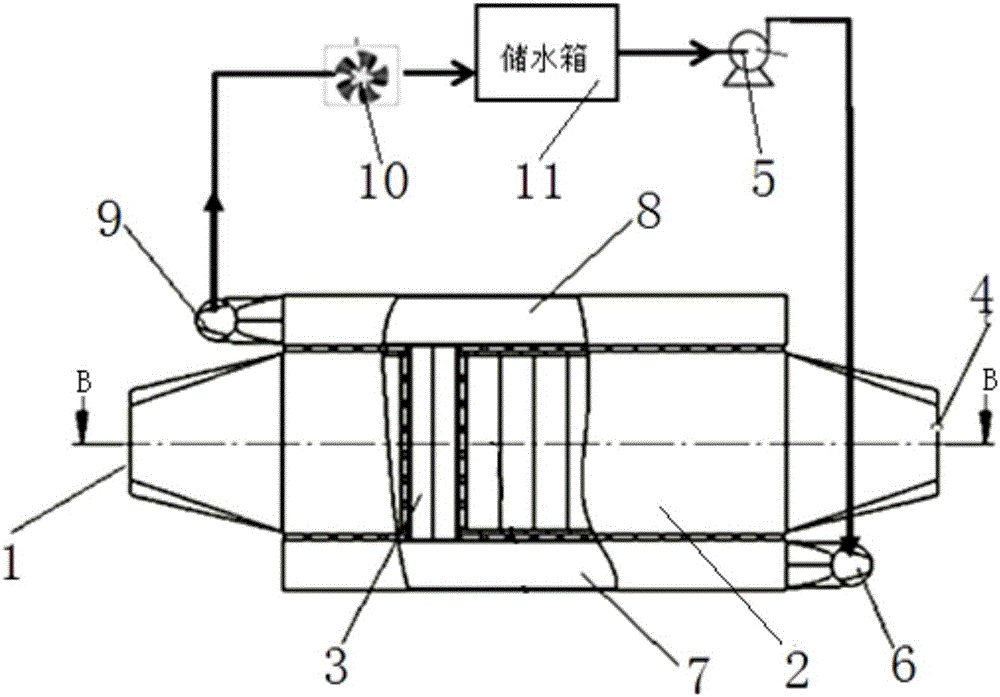

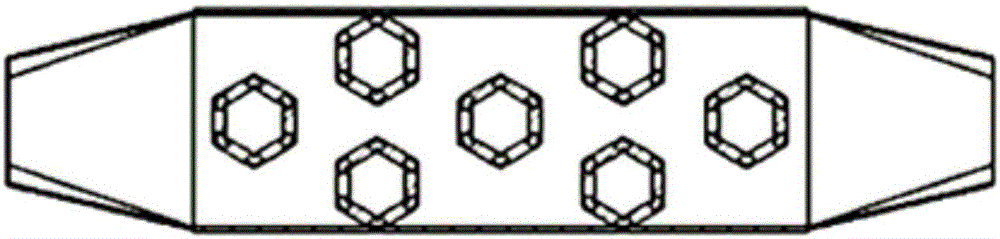

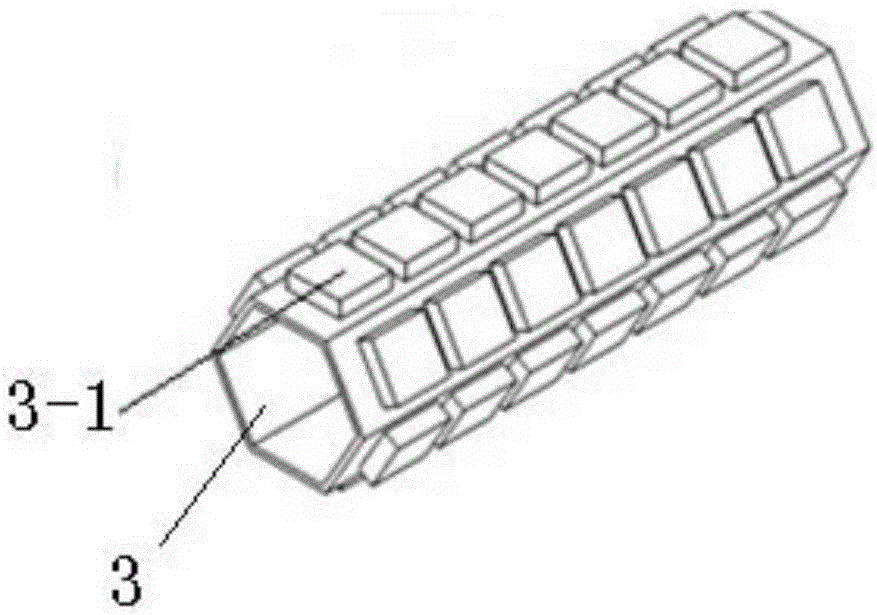

[0029] Such as Figures 1 to 4 shown. The present invention describes a waste heat power generation device of an internal combustion engine, which includes an exhaust gas passage body 2 connected in series to the hot end pipeline of the exhaust pipe of the internal combustion engine, a cooling water pipe 3 arrayed in the exhaust passage body 2, and a cooling water pipe attached and distributed in the cooling water A plurality of thermoelectric power generation modules 3 - 1 on the outer surface of the pipeline 3 , and a cooling water circulation supply system for circulating the cooling water in the cooling water pipeline 3 .

[0030] The cooling water pipe 3 is an array composed of a plurality of cooling water pipes. The cooling water pipes 3 are spaced apart from each other and vertically distributed inside the exhaust gas passage body 2 .

[0031] The cooling water circulation supply system includes the water outlet of the water outlet main pipe 8, the cooling water air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com