fan

A fan and fan blade technology, applied in the field of fans with heat dissipation structure, can solve problems such as shortening the life of motor bearings, and achieve the effects of reducing noise, reducing stagnation area and turbulence, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] A fan according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

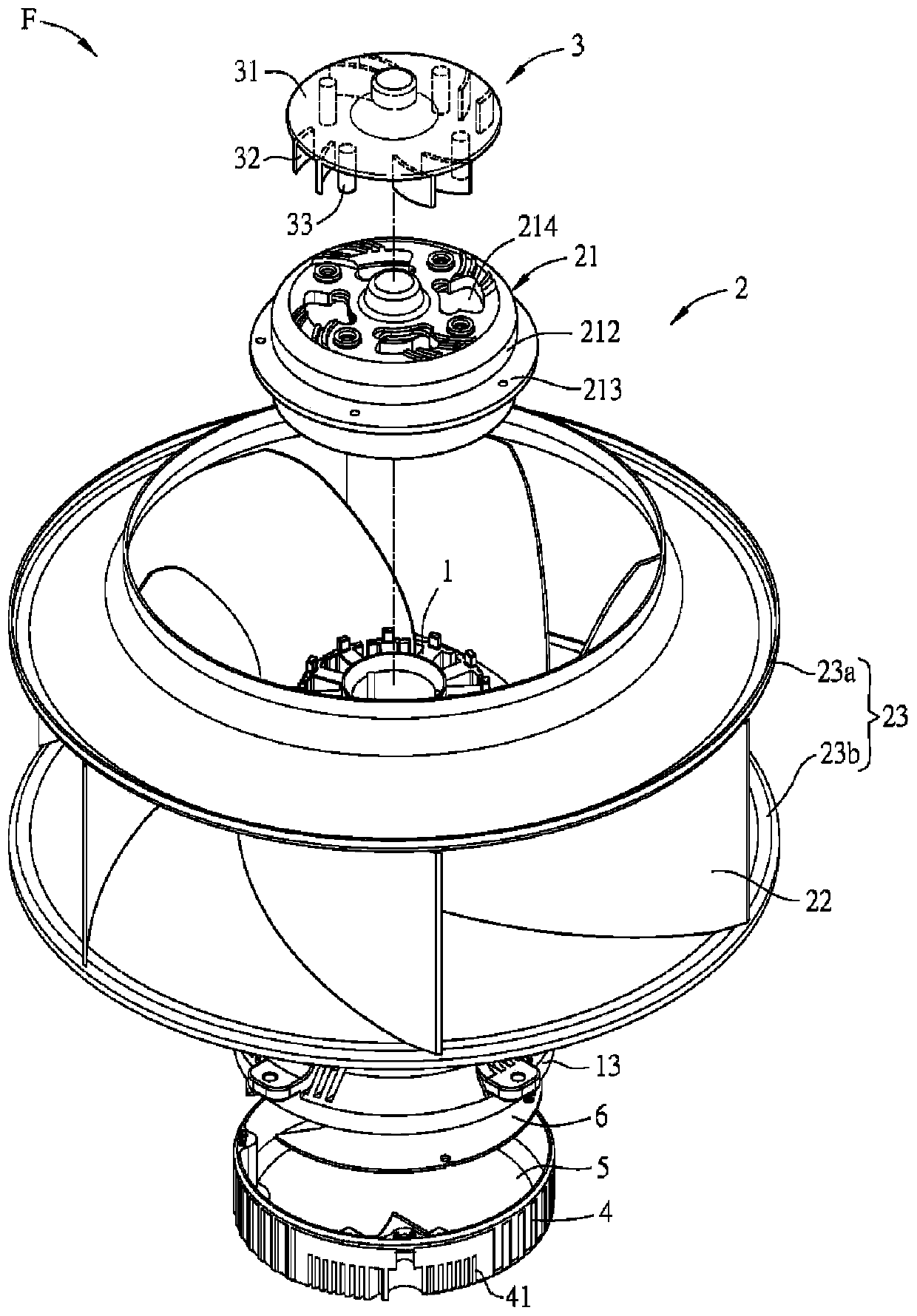

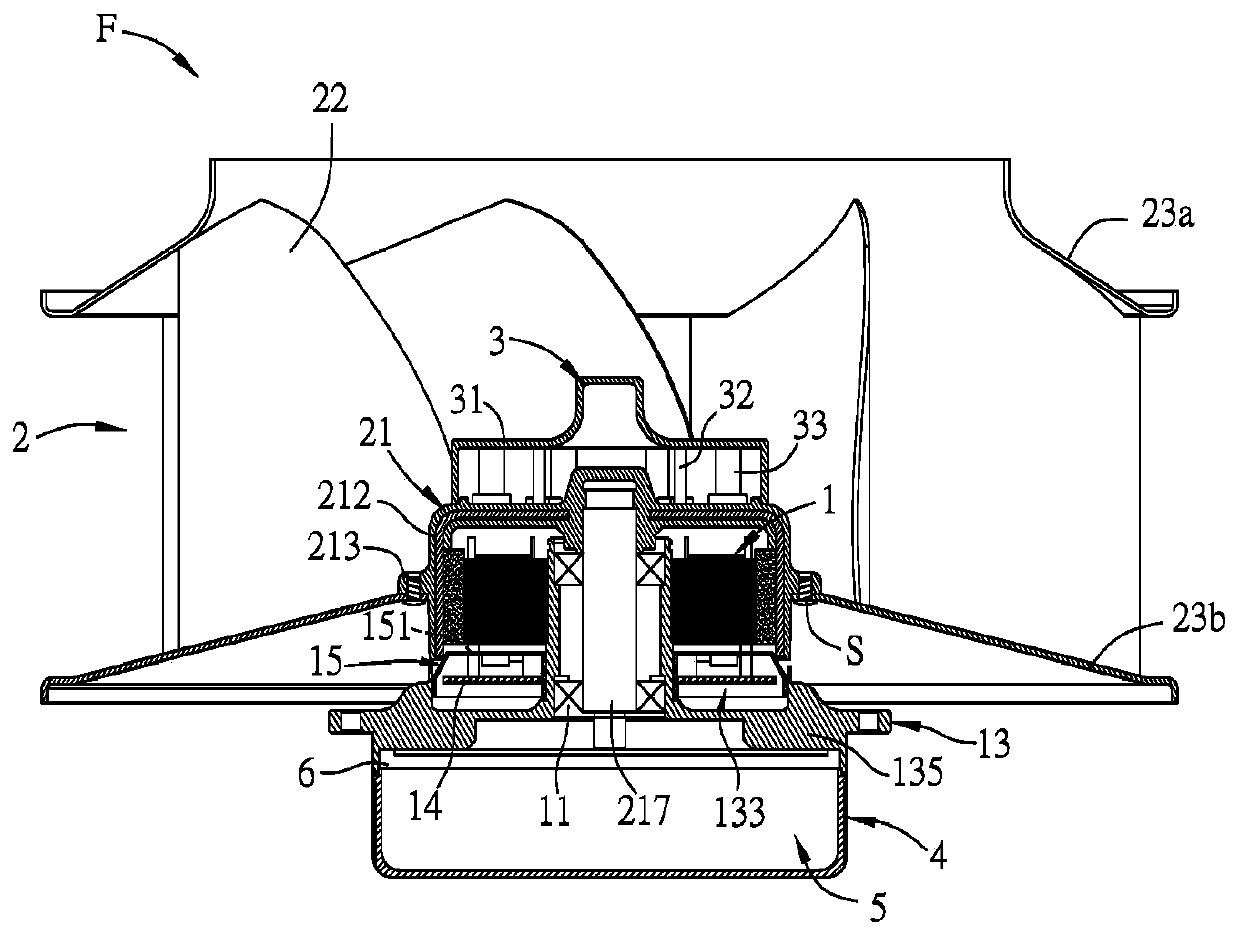

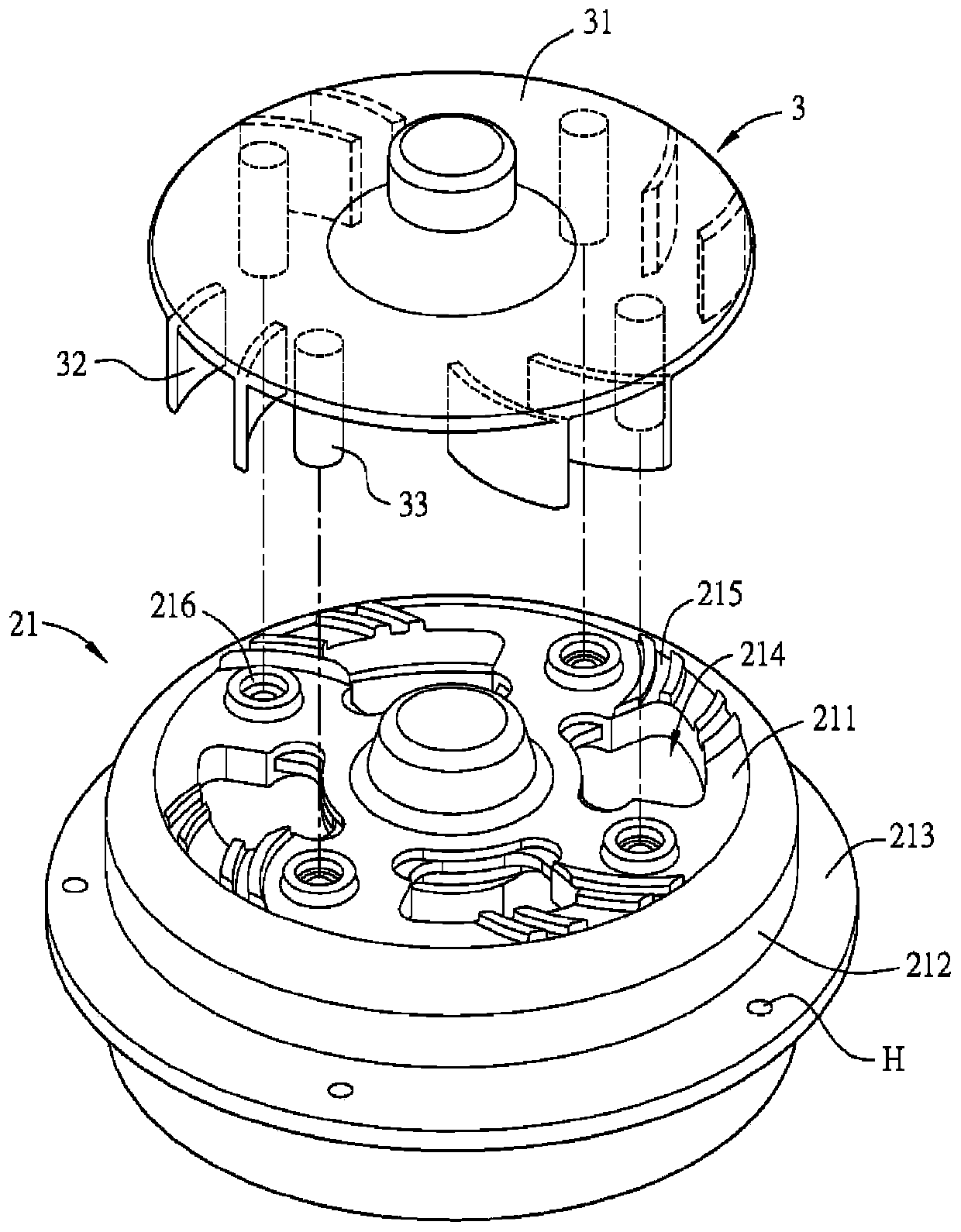

[0095] Figure 1A It is a three-dimensional exploded top view of a fan in a preferred embodiment of the present invention, Figure 1B for Figure 1A Sectional view of the fan shown, please also refer to Figure 1A and Figure 1B shown. The fan F includes a motor 1 , an impeller 2 and a heat dissipation structure 3 . The impeller 2 includes a hub 21 and a plurality of outer fan blades (or first fan blades) 22 . Wherein the hub 21 is a hollow structure, which is used to accommodate the motor 1 and can be divided into a top 211 and a side wall 212 surrounding its outer periphery according to the structure of the hub 21, such as figure 2 shown.

[0096] Please refer to Figure 1A and 1B As shown, the impeller 2 also has two annular structures 23 , and the outer fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com