Method for blocking holes of secondary cables in relay protection screen cabinet of substation

A relay protection screen, secondary cable technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of damage, low reuse rate of fireproof mud, low sealing of cable threading holes, etc. Simple construction and excellent fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

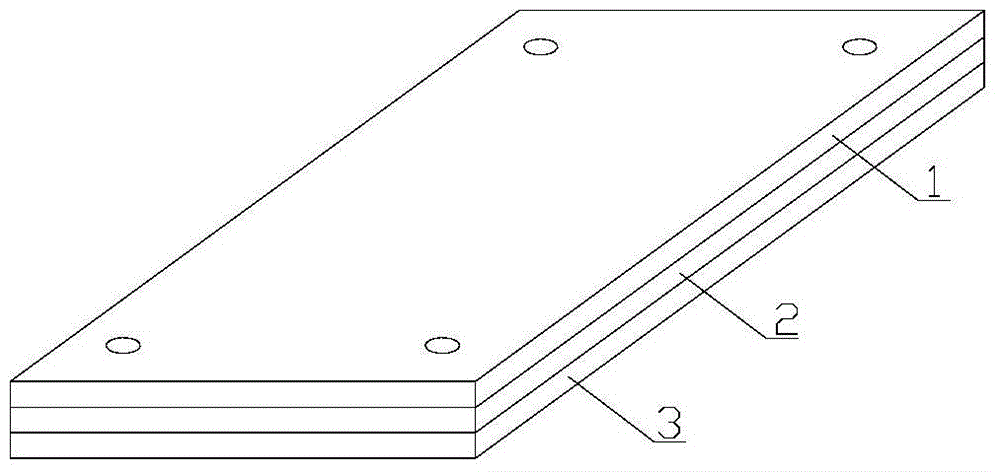

[0028] Such as figure 1 As shown, the foam board is used to seal the secondary cable hole in the substation relay protection screen cabinet, including the upper layer of phenolic resin foam board 1, the middle layer of rigid polyurethane foam board 2 and the lower layer of phenolic resin foam board 3, and the upper and lower layers of foam board It is bonded with the foam board in the middle layer by fireproof glue, and bolt holes are reserved at the four corners of the blocked foam board. The length and width of the plugging foam board are 800X500mm. The thickness of the upper layer phenolic resin foam board 1 and the lower layer phenolic resin foam board 3 is 10-20mm. The thickness of the middle layer rigid polyurethane foam board 2 is 10-15mm.

[0029] It is used in the method of sealing the secondary cable hole in the relay protection screen cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com