Split type fresh air machine

A split-type, new fan technology, applied in heating methods, ventilation systems, space heating and ventilation, etc., can solve problems such as loss of energy and increase in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

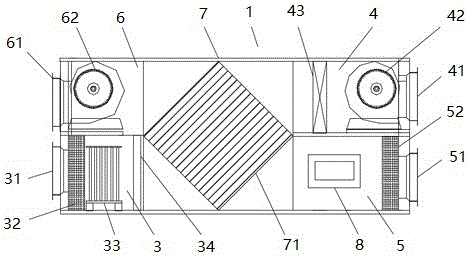

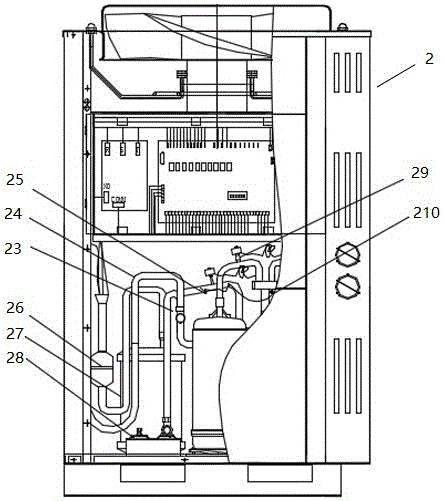

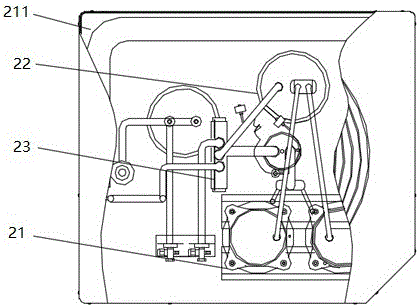

[0017] Embodiment 1: A split type fresh air machine, including an indoor unit 1 and an outdoor unit 2, the indoor unit 1 includes a fresh air chamber 3, an air supply chamber 4, a return air chamber 5, an exhaust chamber 6 and a heat exchange chamber 7; The outer wall of the fresh air chamber 3 is provided with a fresh air interface 31; the outer wall of the air supply chamber 4 is provided with an air supply interface 41; the outer wall of the return air chamber 5 is provided with a return air interface 51; the outer wall of the exhaust chamber 6 An exhaust interface 61 is provided on the top; a total heat exchanger 71 is installed in the heat exchange chamber 7, and the fresh air chamber 3 communicates with the air supply chamber 4, and the return air chamber 5 communicates with the exhaust chamber 6; The chamber 4 is provided with a first centrifugal fan 42; the exhaust chamber 6 is provided with a second centrifugal fan 62; the air supply chamber 4 is provided with an evapo...

Embodiment 2

[0018] Embodiment 2: A split type fresh air machine, including an indoor unit 1 and an outdoor unit 2, the indoor unit 1 includes a fresh air chamber 3, an air supply chamber 4, a return air chamber 5, an exhaust chamber 6 and a heat exchange chamber 7; The outer wall of the fresh air chamber 3 is provided with a fresh air interface 31; the outer wall of the air supply chamber 4 is provided with an air supply interface 41; the outer wall of the return air chamber 5 is provided with a return air interface 51; the outer wall of the exhaust chamber 6 An exhaust interface 61 is provided on the top; a total heat exchanger 71 is installed in the heat exchange chamber 7, and the fresh air chamber 3 communicates with the air supply chamber 4, and the return air chamber 5 communicates with the exhaust chamber 6; The chamber 4 is provided with a first centrifugal fan 42; the exhaust chamber 6 is provided with a second centrifugal fan 62; the air supply chamber 4 is provided with an evapo...

Embodiment 3

[0019] Embodiment 3: A split type fresh air machine, including an indoor unit 1 and an outdoor unit 2, the indoor unit 1 includes a fresh air chamber 3, an air supply chamber 4, a return air chamber 5, an exhaust chamber 6 and a heat exchange chamber 7; The outer wall of the fresh air chamber 3 is provided with a fresh air interface 31; the outer wall of the air supply chamber 4 is provided with an air supply interface 41; the outer wall of the return air chamber 5 is provided with a return air interface 51; the outer wall of the exhaust chamber 6 An exhaust interface 61 is provided on the top; a total heat exchanger 71 is installed in the heat exchange chamber 7, and the fresh air chamber 3 communicates with the air supply chamber 4, and the return air chamber 5 communicates with the exhaust chamber 6; The chamber 4 is provided with a first centrifugal fan 42; the exhaust chamber 6 is provided with a second centrifugal fan 62; the air supply chamber 4 is provided with an evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com