Power battery module structure for locomotive

A technology of power battery and module structure, applied in the direction of batteries, secondary batteries, structural parts, etc., can solve the problems of lack of safety protection measures in the power battery system, inability to know potential safety hazards in time, complicated production and assembly processes, etc., and achieve rapid cooling. The effect of battery, saving production cycle and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

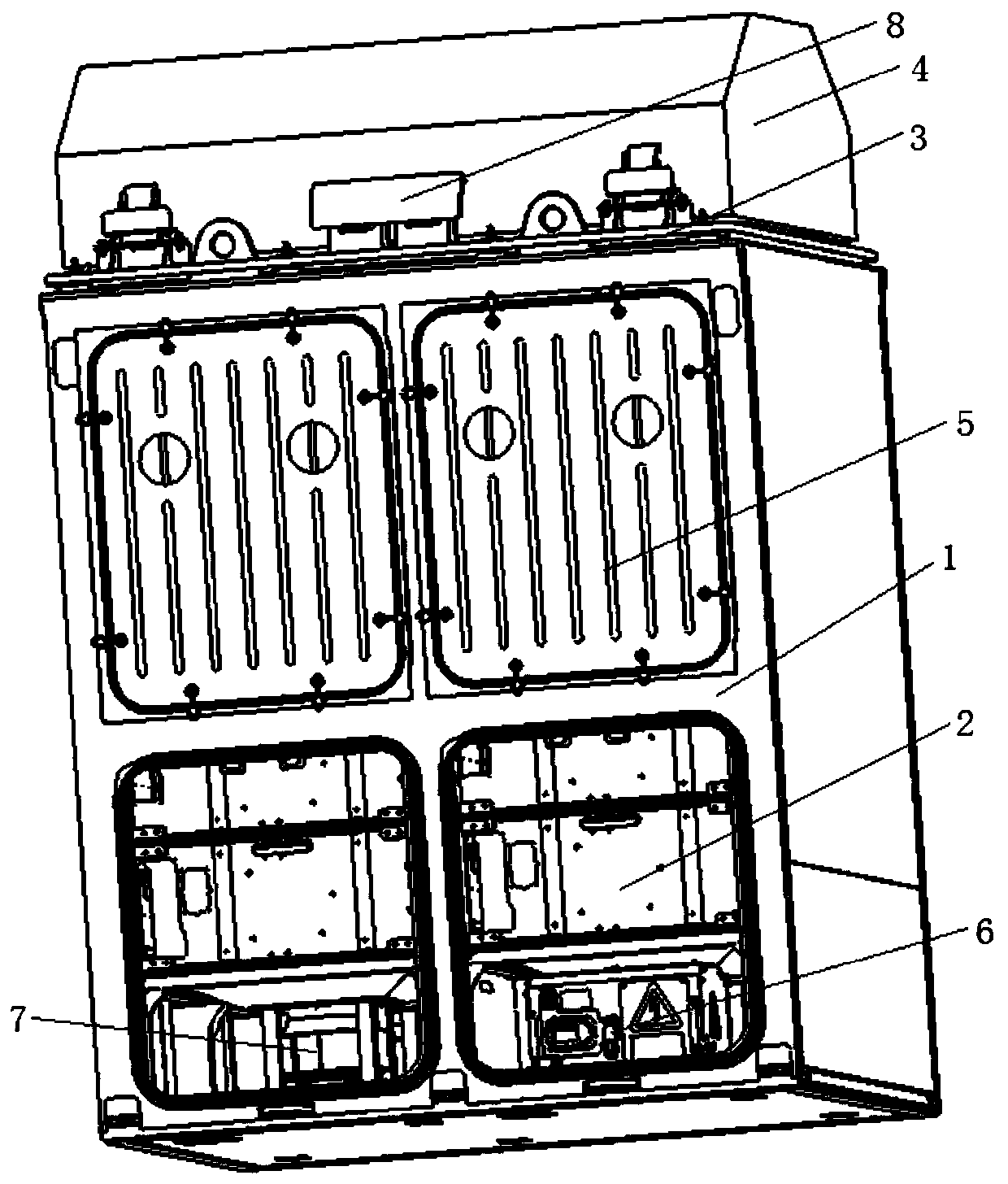

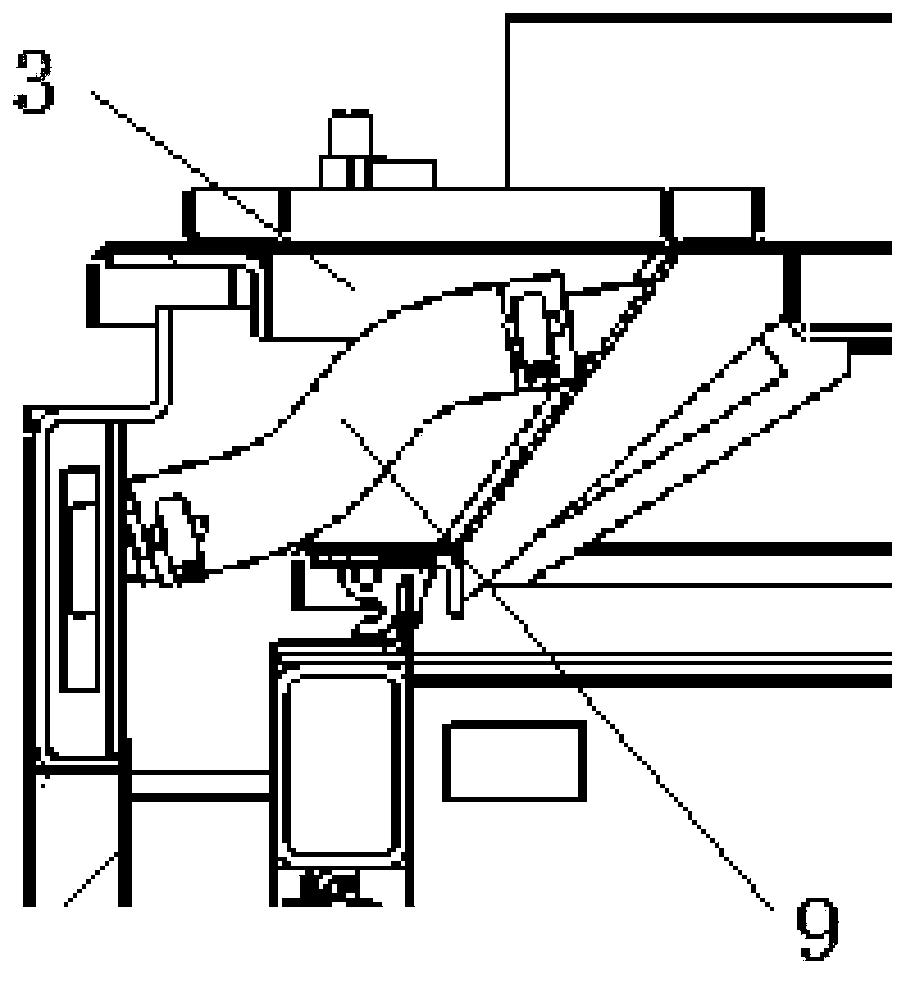

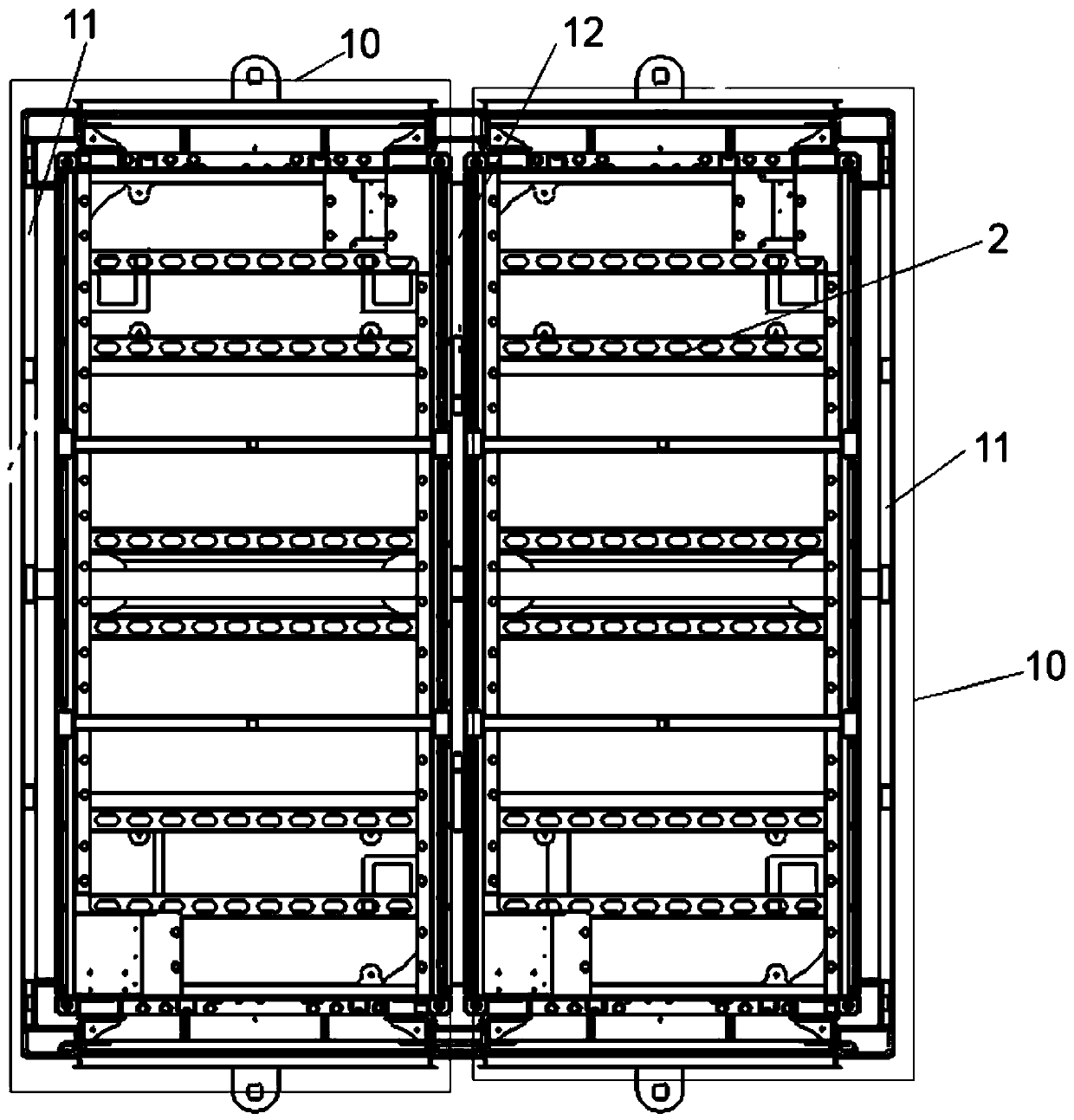

[0041] like figure 1 As shown, in this embodiment, a power battery module structure for a locomotive is specifically provided, including a casing 1 made of a steel structure to serve as a carrier for the entire module structure. Inside the casing 1 There are two power battery compartments 10 arranged side by side, and the two ends of each power battery compartment 10 are respectively provided with a battery compartment air inlet and a battery compartment air outlet, the battery compartment air inlet, the inner cavity of the power battery compartment 10 and the battery compartment The air outlet is connected to form the cooling air duct, which is used to circulate the cold air discharged through the air conditioning unit 4, and realize the heat exchange between the cold air and the heat generated by the power battery pack 2 in the cooling air duct; the power battery compartment A return air duct 13 is provided between the exterior of 10 and the housing 1 , and the return air du...

Embodiment 2

[0062] If the battery is thermally out of control, the electric energy and chemical energy inside the battery are released, and the battery will generate flammable gas, which will heat up and deflagrate. In order to further improve the fireproof and heat insulation effect of the power battery module structure, a The bottom, the side of the casing 1 and the side of the battery cavity all adopt firewalls, on the basis of Embodiment 1, such as Figure 7 As shown, the shell plate 11 on the side and bottom of the installation frame is replaced with a firewall, and the middle partition 12 that forms the power battery compartment 10 is also used as a protective wall, and the inspection door 5 and the top cover 3 The inner surfaces of the two power battery compartments 10 in Example 1 are all coated with fireproof paint, so as to finally realize the complete physical isolation of the two power battery compartments 10 in Example 1.

[0063] The firewall arranged outside the casing 1 an...

Embodiment 3

[0067] In order to further improve the fire protection system of the power battery module structure, such as Figure 9As shown, one side of the inspection door 5 is hinged on the housing 1 through a hinged shaft, and the other side is equipped with a door locking mechanism that controls the opening or closing of the inspection door 5. The door locking mechanism includes an electromagnet 20. Spring and controller. The inspection door 5 is adsorbed on the electromagnet 20 by overcoming the elastic force of the spring, and the electromagnet 20 is electrically connected to the controller. The controller is connected with a control button. When the user presses the operation button , the corresponding electromagnet 20 can be controlled to be disconnected or connected, so that the maintenance door 5 will be opened under the elastic action of the spring or be firmly adsorbed by the magnetic force of the electromagnet 20. In this embodiment, the spring can be a torsion spring And inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com