Heat source machine

A heat source machine and latent heat technology, applied in fluid heaters, lighting and heating equipment, combustion methods, etc., can solve problems such as nozzle hole clogging and gas not coming out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

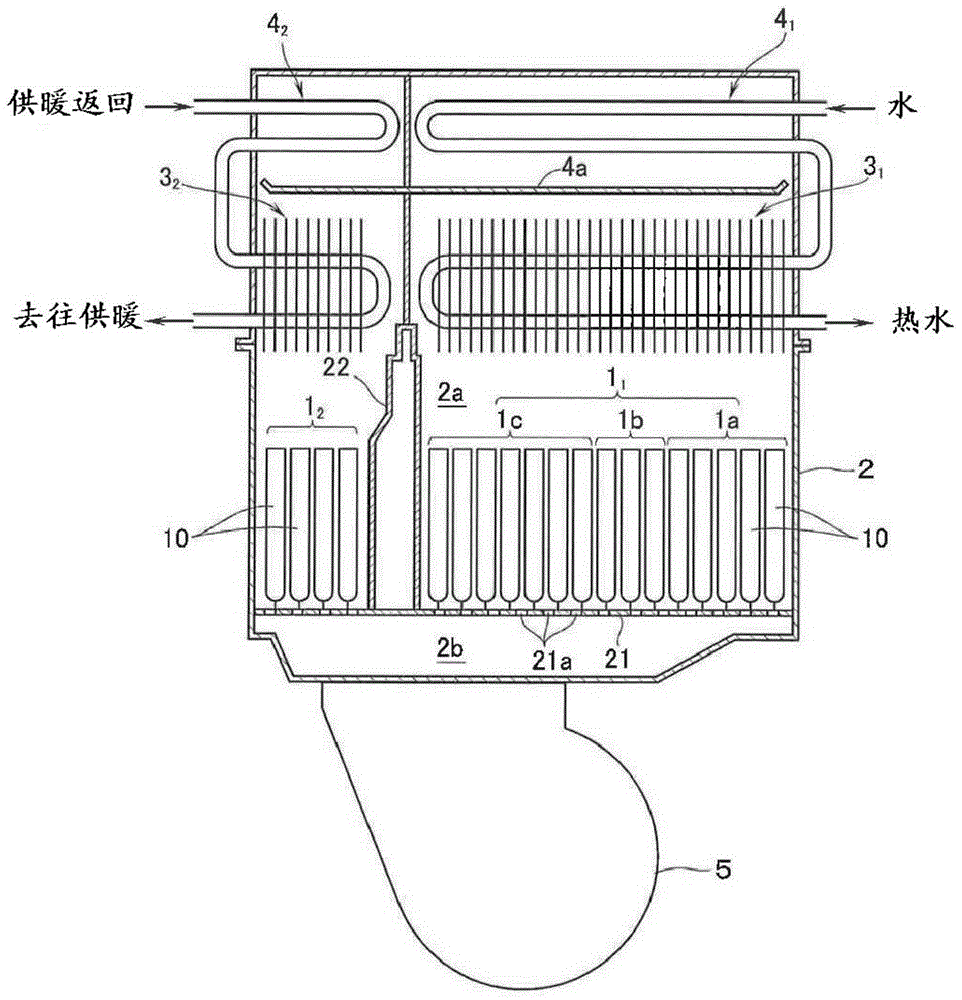

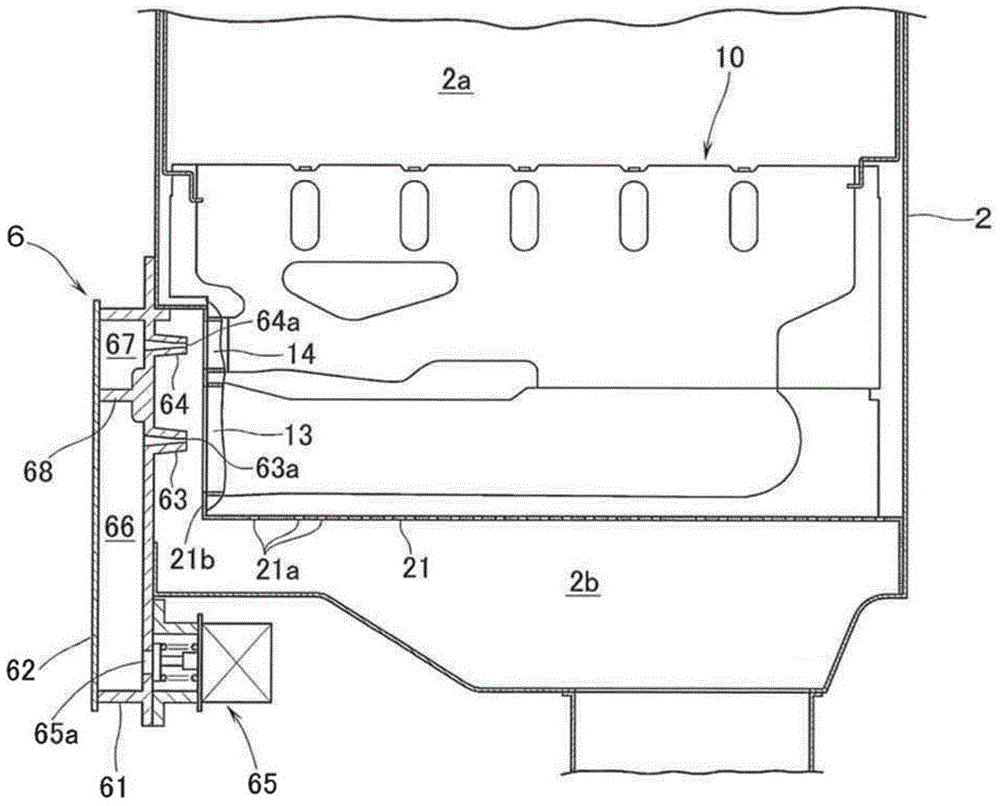

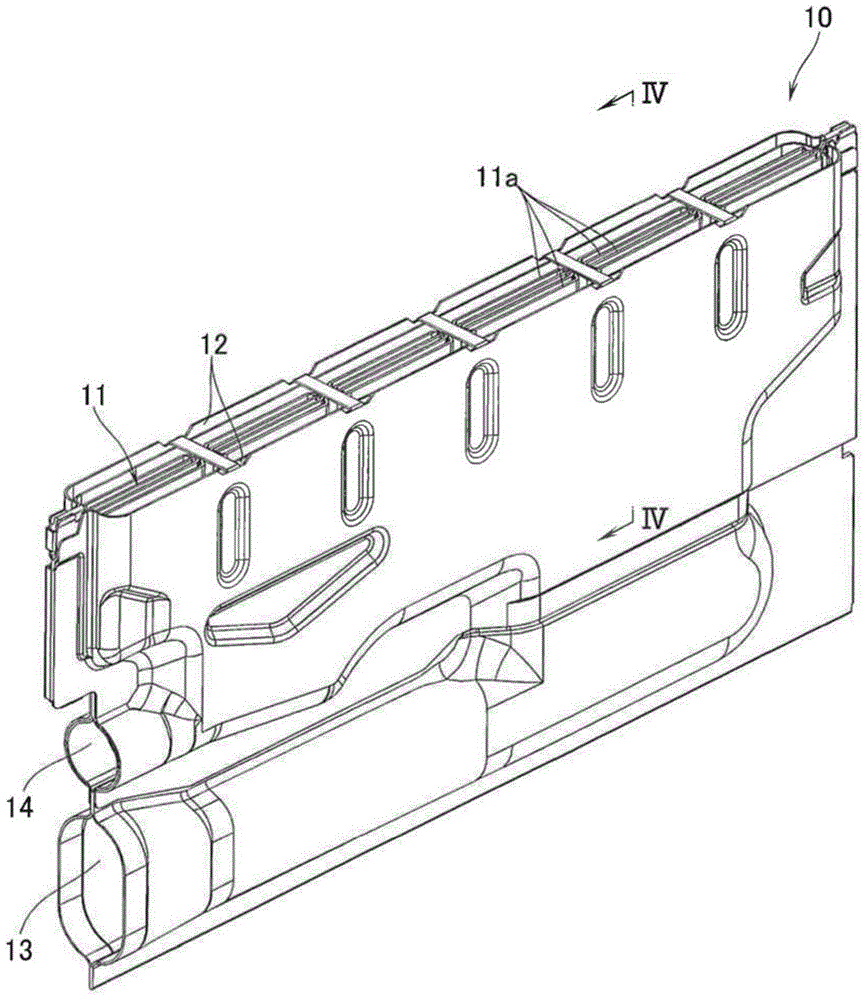

[0017] figure 1 The heat source unit according to the embodiment of the present invention shown is a device for supplying hot water and heating, and the first burner unit 1 for supplying hot water 1 and 2nd burner unit 1 for heating 2 On top of the built-in combustion shell, the 1st burner unit 1 is arranged side by side 1 The first sensible heat recovery type heat exchanger 3 for hot water supply heated by combustion exhaust gas 1 , and using the second burner unit 1 2 The second sensible heat recovery type heat exchanger 3 for heating to heat the combustion exhaust gas 2 , and then, in the first sensible heat recovery heat exchanger 3 1 The first latent heat recovery type heat exchanger 4 for supplying hot water is arranged above 1 , the first latent heat recovery type heat exchanger 4 1 recovery through the 1st sensible heat recovery type heat exchanger 3 1 The latent heat in the combustion exhaust, moreover, in the 2nd sensible heat recovery type heat exchanger 3 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com