Chemical fertilizer drying machine

A drying machine and fertilizer technology, applied in the field of drying, can solve the problems of wind dead angle, insufficient drying, inconvenient fertilization, etc., and achieve the effect of avoiding wind dead angle, improving processing quality and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

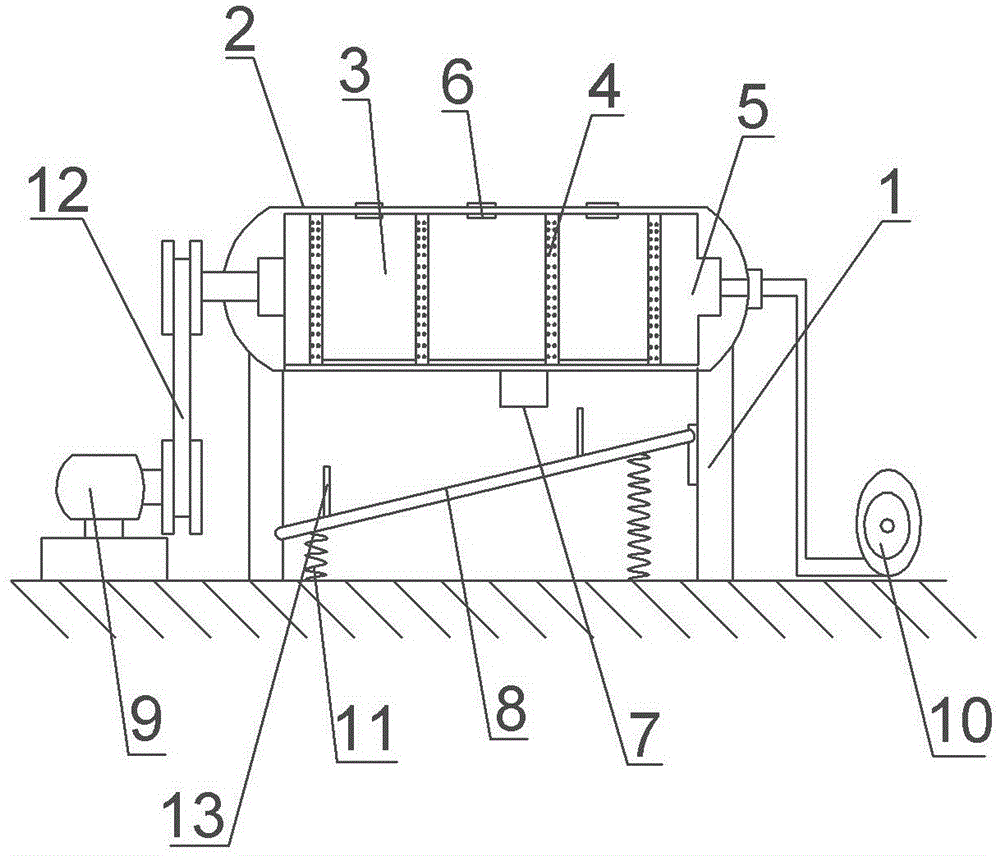

[0012] The reference signs in the accompanying drawings of the description include: frame 1, cylinder body 2, drying chamber 3, exhaust pipe 4, rotating cylinder 5, feed port 6, discharge port 7, sieve plate 8, motor 9, Fan 10, spring 11, belt 12.

[0013] The embodiment is basically as attached figure 1 Shown: cylinder 2 is a kind of fertilizer dryer, including frame 1, motor 9, belt 12, rotating cylinder 5, the rotating shaft running through the rotating cylinder 5 and the cylinder 2 arranged outside the rotating cylinder 5, the motor 9 passes through The belt 12 is connected to one end of the rotating shaft, and several feeding ports 6 are arranged on the top of the cylinder shell; four exhaust pipes 4 are arranged inside the rotating cylinder 5, and the exhaust pipes 4 divide the rotating cylinder 5 into several drying chambers 3 Each drying chamber 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com