Feeding, cleaning, gasket installing and closing-in integrated machine for fire work columnar shells

A cylindrical shell, integrated machine technology, applied in weapon accessories, ammunition, offensive equipment and other directions, can solve the problems of low work efficiency, high labor intensity, large labor volume, etc., to improve the operation level, low labor intensity, high installation The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

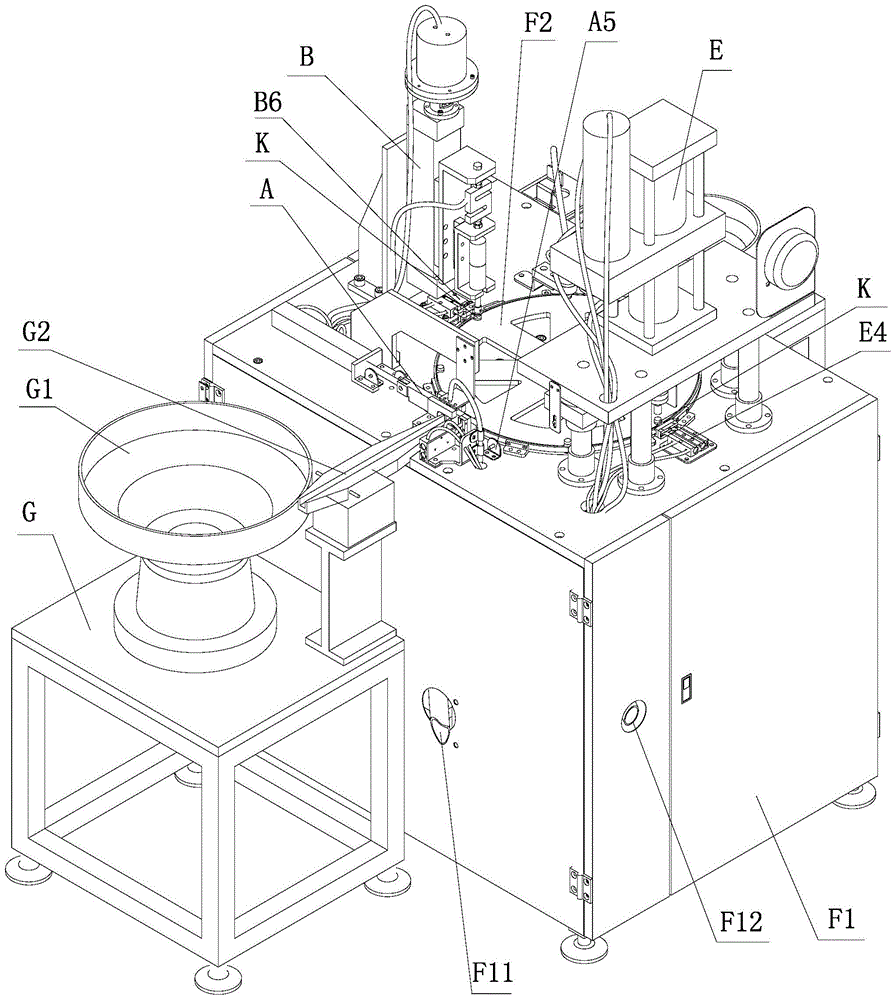

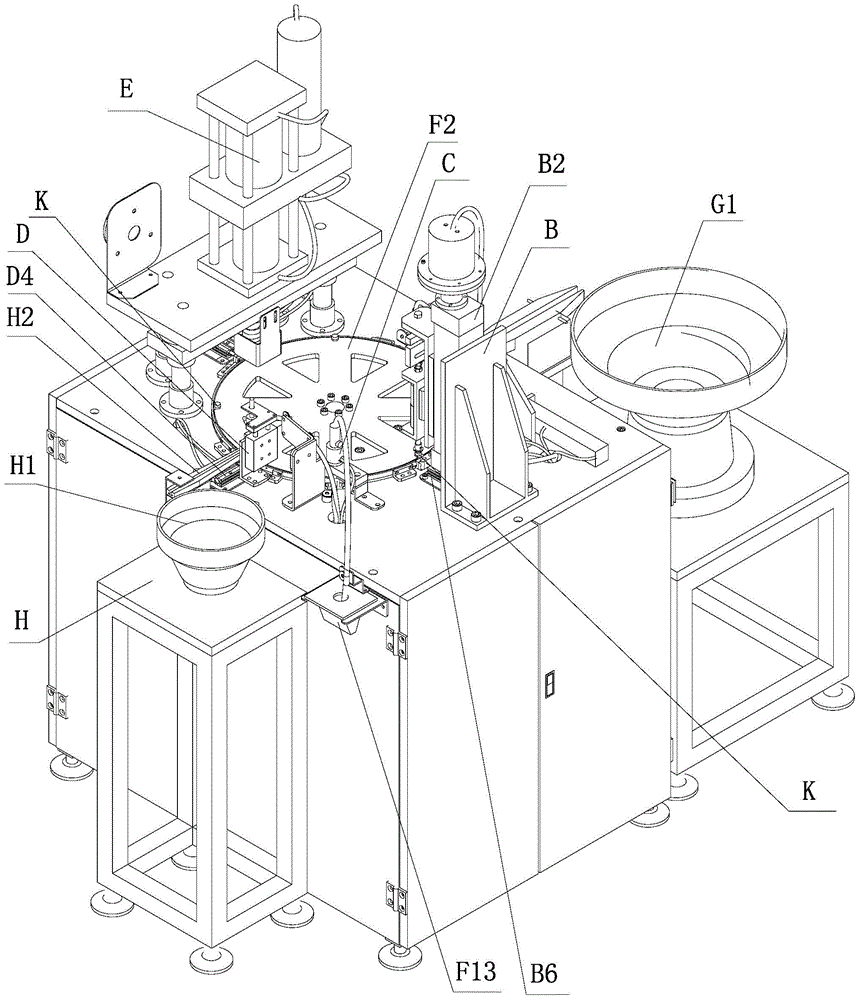

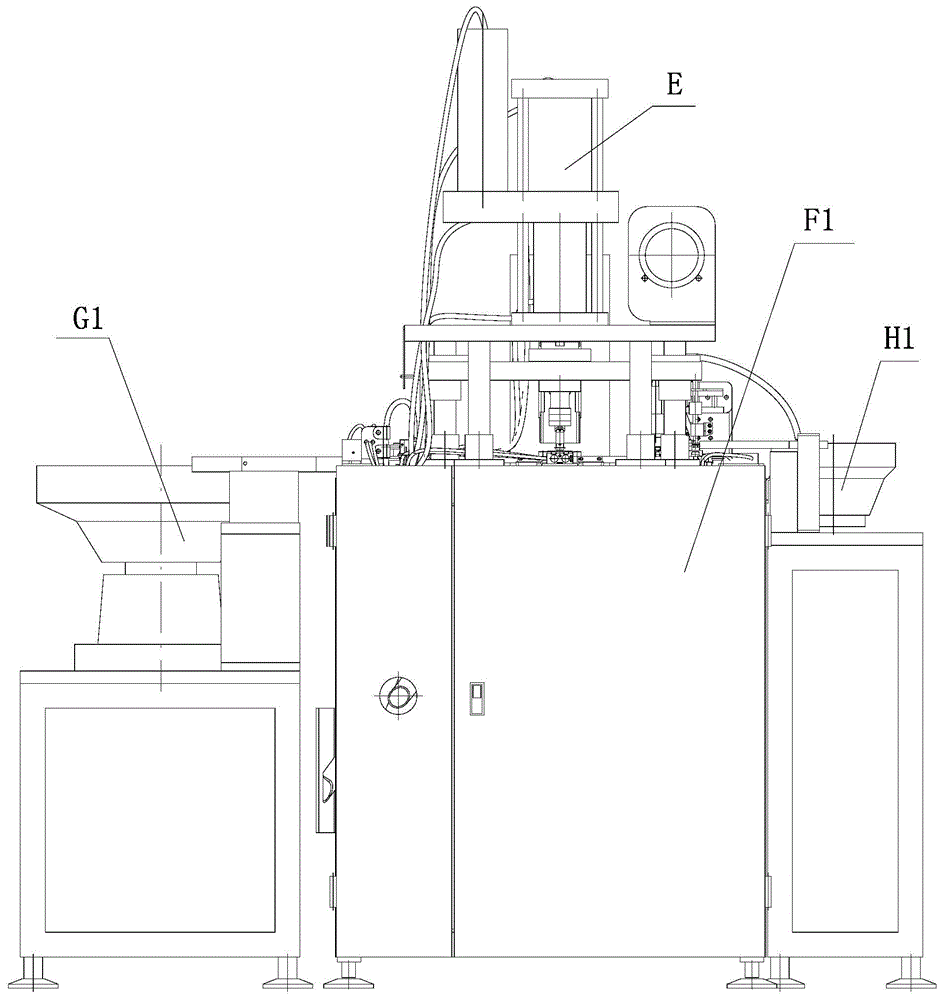

[0011] Specific implementation mode one: combine Figure 1-Figure 9 Explanation, the pyrotechnic columnar shell feeding, cleaning, padding and closing machine of this embodiment includes a shell feeding mechanism G and a gasket feeding mechanism H; it also includes a host; the host includes a main frame F1 and a rotary station mechanism F2, Detection station mechanism A, cleaning station mechanism B, ash suction station mechanism C, padding station mechanism D, closing station mechanism E and closing clamping assembly E4;

[0012] Shell feeding mechanism G and gasket feeding mechanism H are respectively arranged on the opposite sides of the main base F1, and a rotary station mechanism F2 is installed on the main base F1, and the shell feeding mechanism G is used to transport the pyrotechnic cylindrical shell to the rotary station Mechanism F2 and rotary station mechanism F2 are used to transfer pyrotechnic cylindrical shells to detection station mechanism A, cleaning station m...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-Figure 2 and Figure 6 Explain that the cleaning station mechanism B in this embodiment includes a cleaning station bracket B7, a power motor B1, a linear movement assembly B2, a pressure sensor B3, a drive motor B4, a cleaning knife B5 and a cleaning clamping assembly B6; the cleaning clamping assembly B6 Including cleaning clamping cylinder B61 and cleaning clamping piece B62;

[0019] The cleaning station bracket B7 is installed on the main frame F1, the power motor B1 is installed on the cleaning station bracket B7, the output shaft of the power motor B1 is vertically arranged, and the output shaft of the power motor B1 is connected to the linear moving component B2 and drives the linear moving component B2 Moving up and down, a drive motor B4 is installed on the linear movement component B2, the output shaft of the drive motor B4 is vertically arranged, and a pressure sensor B3 connected with the drive motor ...

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 1-Figure 2 and Figure 7 Note that the cushioning station mechanism D in this embodiment includes a cushioning station support D1, a cushioning cylinder D2, a cushioning push rod D3, a cushioning clamping assembly D4, and a cushioning photoelectric sensor D5; the cushioning clamping assembly D4 Including cushioning cylinder D41 and cushioning clamp D42;

[0021] The cushioning station support D1 is installed on the main base F1, the cushioning displacement sensor D5 and the cushioning cylinder D2 are installed on the cushioning station support D1, the piston rod of the cushioning cylinder D2 moves vertically, and the cushioning push rod D3 It is arranged side by side with the piston rod of the pad feeding cylinder D2 and the two are detachably connected as one. The pad feeding displacement sensor D5 is set adjacent to the pad feeding push rod D3. The pad clamping cylinder D41 is installed on the pad loading statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com