System for detecting gas tightness of compressed natural gas dispenser

A technology of air tightness detection and compressed natural gas, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and detecting the appearance of fluid at the leakage point, etc., can solve the problem that the effect of the pressure holding value is not obvious, and achieve the detection effect Intuitive and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

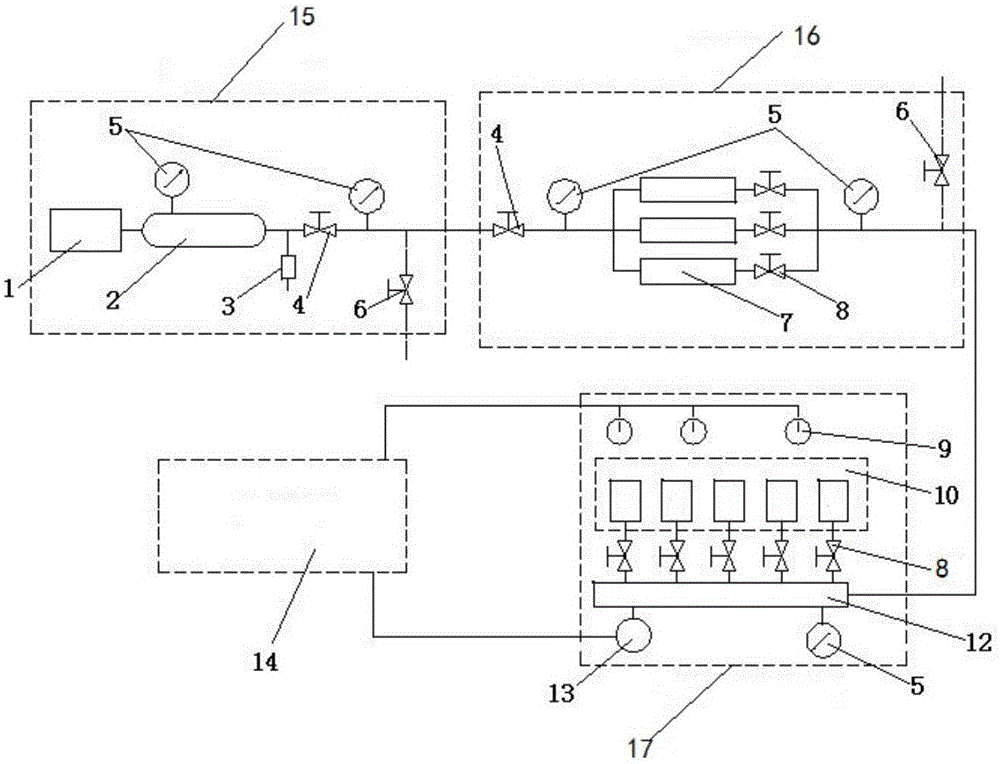

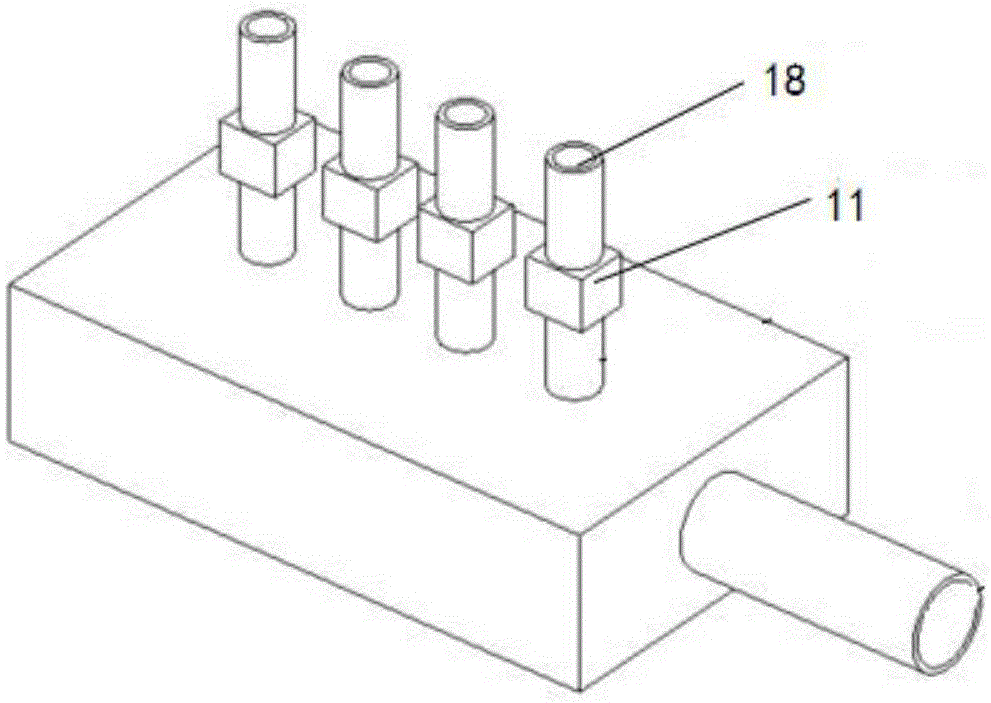

[0021] Such as Figure 1-2 As shown, a compressed natural gas dispenser airtightness detection system includes gas source generating equipment 15, pressure regulating equipment 16, airtightness testing equipment 17 and monitoring equipment 14, the output end of the gas source generating equipment 15 is connected to the pressure regulating Equipment 16, air tightness detection equipment 17 are used to connect pressure regulating equipment 16, and gas source generating equipment 15 comprises high-pressure compressor 1, and the output end of high-pressure compressor 1 is connected with high-pressure gas storage container 2, and the output of high-pressure gas storage container 2 There is a cut-off valve 4 connected to the end, and a safety valve 3 is provided between the cut-off valve 4 and the high-pressure gas storage contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com