Ultrasonic effect evaluation component and method

An evaluation method, ultrasonic technology, applied in semiconductor/solid-state device testing/measurement, etc., can solve problems such as difficulty in obtaining accurate data, misjudgment of ultrasonic performance of ultrasonic cleaning equipment, and disputes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

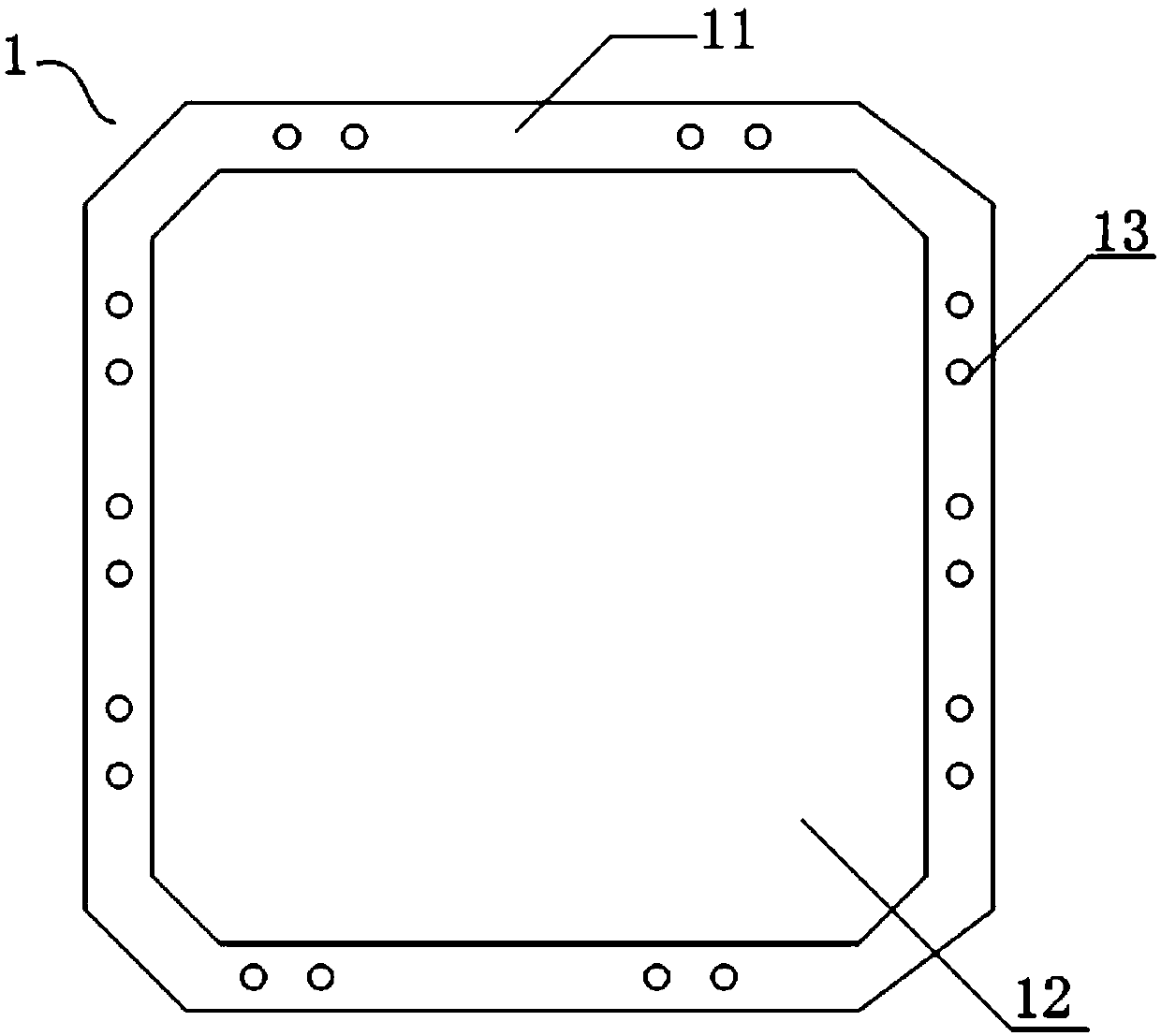

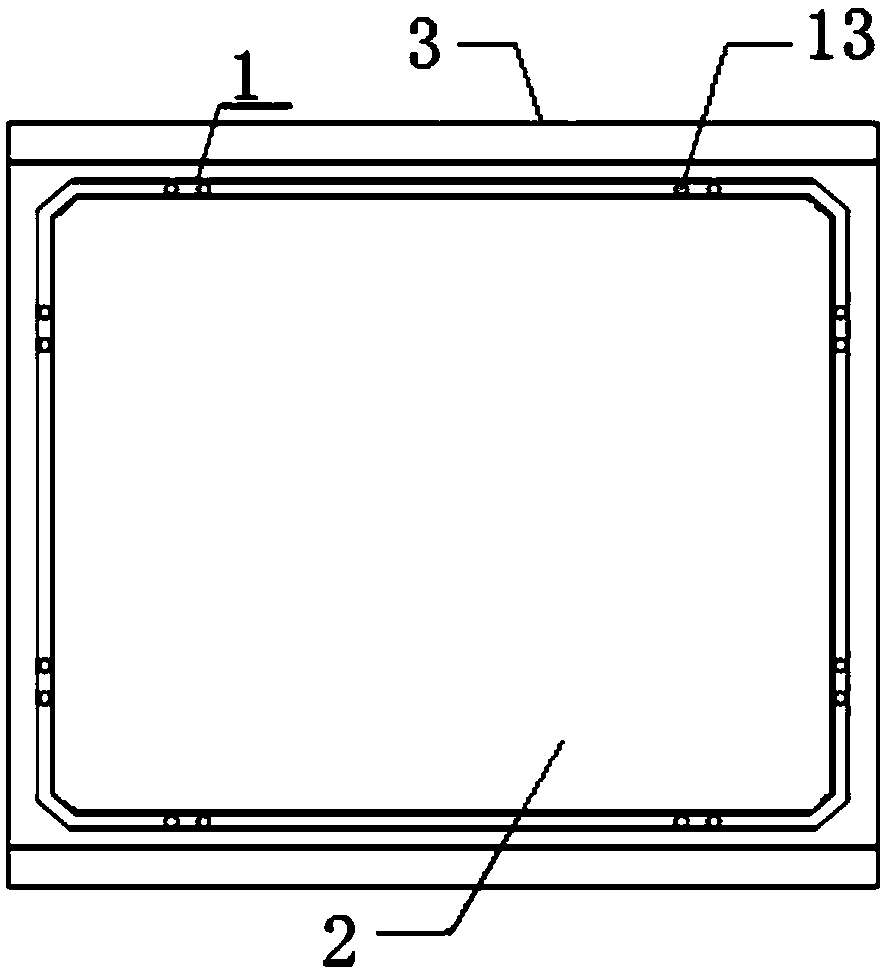

[0030] This embodiment provides an ultrasonic effect evaluation component for evaluating the ultrasonic effect of an ultrasonic cleaning device. This ultrasonic effect evaluation component includes at least one such as figure 1 The supporting frame 1 shown, and the membrane layer 2 arranged on the surface of the supporting frame 1 , preferably, the membrane layer 2 is detachably arranged on the surface of the supporting frame 1 . The ultrasonic cleaning device applies ultrasonic action to the membrane layer 2 .

[0031] The supporting frame 1 mainly plays a role of fixing and supporting the spreading of the film layer 2 , and it is a frame structure including an outer frame body 11 . The film layer 2 is fixed on the frame body 11 and at least partially covers the area surrounded by the frame body 11 , where the area is the hollow portion 12 inside the frame body 11 . The film layer 2 is laid to cover the hollow portion 12 and fixed to the frame portion 11. It should be point...

Embodiment 2

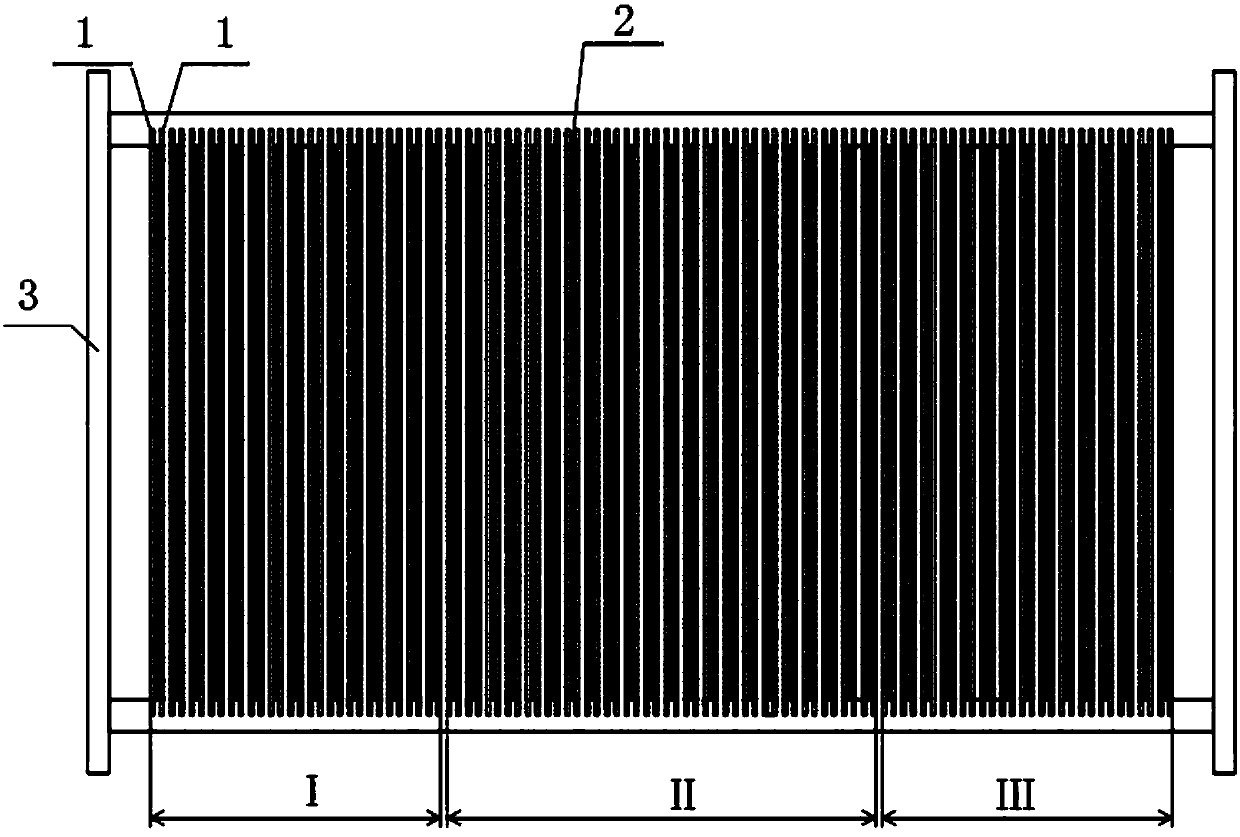

[0036] This embodiment provides another ultrasonic effect evaluation component, such as figure 2 and image 3As shown, two supporting frames 1 are included, and the film layer 2 is sandwiched between the two supporting frames 1 . Regarding the structural setting and manufacturing materials of the supporting frame 1, and the fixing method of the film layer 2 on the supporting frame 1, please refer to Embodiment 1, and details are not repeated here. It should be pointed out that the shape and size of the two support frames 1 can be consistent (same) or slightly different, but this difference should not affect the evaluation of the ultrasonic effect of the ultrasonic cleaning equipment.

[0037] The manufacturing method of this ultrasonic effect evaluation component can be roughly described as: taking two supporting frames 1; clamping the film layer 2 with the two supporting frames 1 and performing necessary fixing; cropped.

[0038] During the processing of silicon wafers, u...

Embodiment 3

[0041] This embodiment provides a specific ultrasonic effect evaluation component, which is used to evaluate the ultrasonic effect of ultrasonic cleaning equipment. The supporting frame 1 is made of stainless steel, the hollow part (inner frame) is 156mm×156mm in size, which is equivalent to the length and width of silicon wafers; the frame body (outer frame) is 170mm×170mm in size and 1mm thick, and is processed in the frame body 16 M5 threaded holes for locking tin foil. The tin foil should be the thickness of the packaging film. It is best to choose tin foil from the same manufacturer. Different manufacturers have different thickness and strength of tin foil, which will affect the test results. Two stainless steel support frames clamp the tin foil, cut off the excess tin foil with scissors, and then lock the stainless steel support frame with screws, and the ultrasonic effect evaluation component is completed. When fixing the tin foil, try to ensure that the test surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com